An adjustable injection mold

An injection mold, adjustable technology, applied in the field of molds, can solve the problem of inability to adjust the size of injection molding castings, and achieve the effect of reducing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

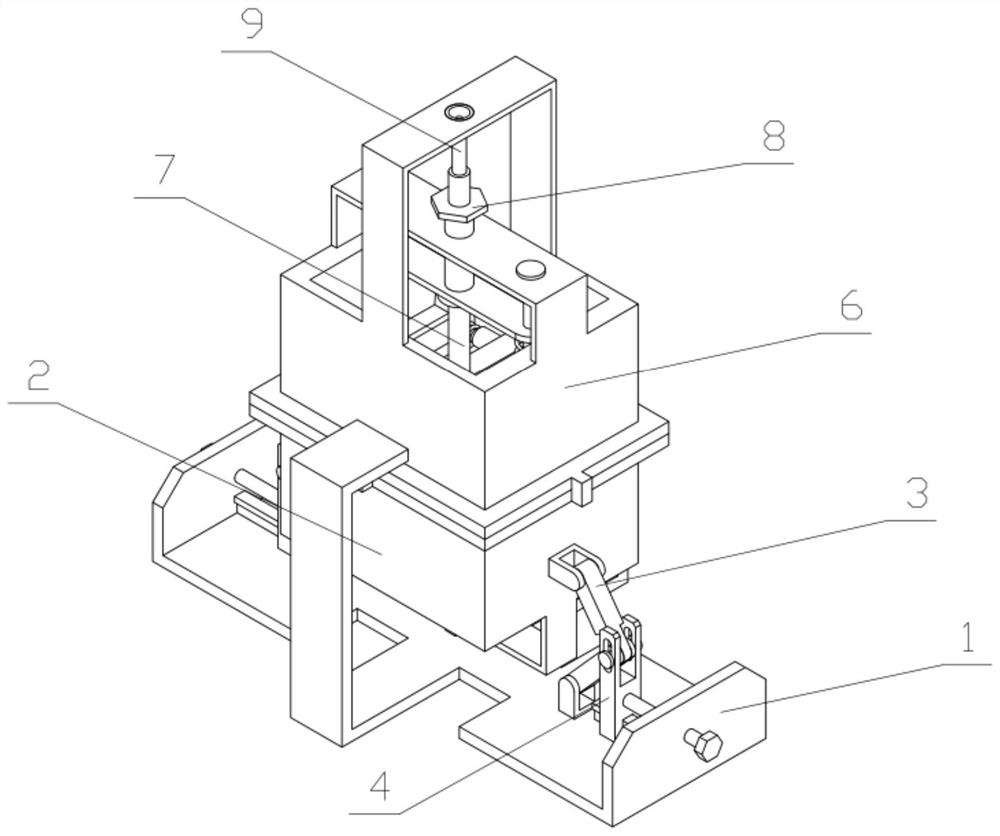

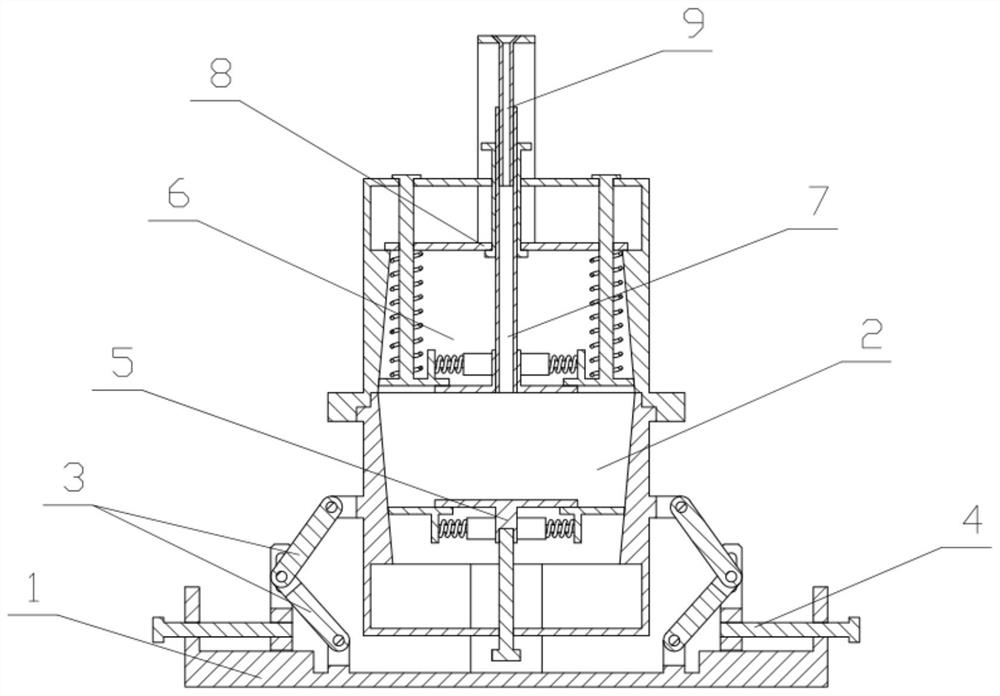

[0036] Combine below Figure 1-12 Describe this embodiment, an adjustable injection mold, including a device bracket 1, a molding mold I2, a demoulding link 3, a demoulding mechanism 4, an adjustment mechanism 5, a molding mold II6, an extrusion mechanism 7, a pretensioning mechanism 8 and Injection tube 9, both sides of the device bracket 1 are hinged with demoulding connecting rods 3, both sides of forming mold I2 are hinged with demoulding connecting rods 3, and the inner sides of the two demoulding connecting rods 3 on both sides are connected to each other. Hinged on the demoulding mechanism 4, the two demoulding mechanisms 4 are slidingly connected to the device bracket 1, and the adjusting mechanism 5 whose horizontal height can be changed is arranged in the forming mold I2, and the forming mold II6 is stuck on the forming mold I2, and the forming mold II6 is provided with an extruding mechanism 7 whose horizontal height can be changed, and a compression spring III is a...

specific Embodiment approach 2

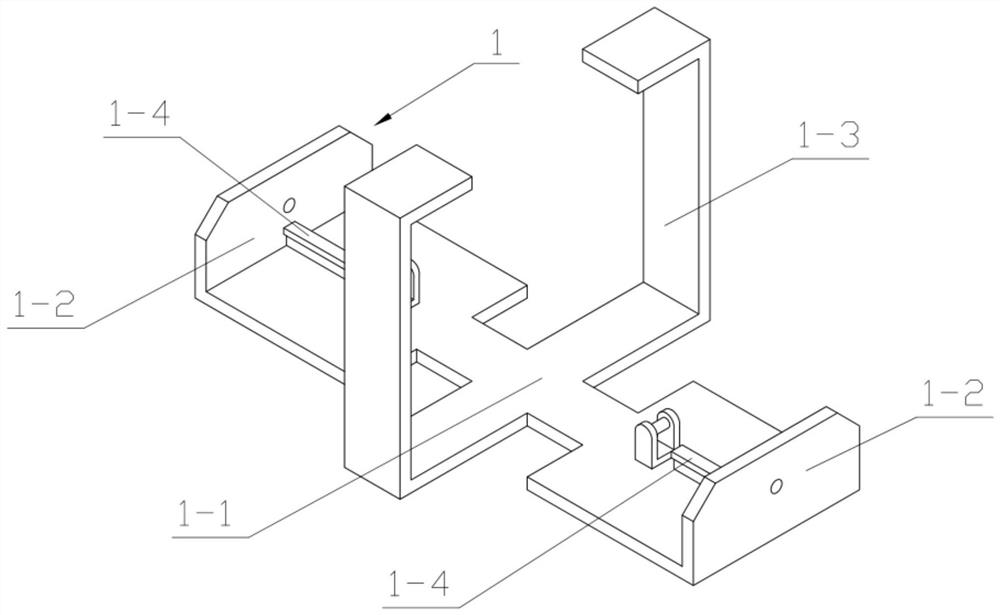

[0038] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the first embodiment, the device bracket 1 includes a bottom plate 1-1, a side plate 1-2, a support plate 1-3 and a T-shaped slide rail 1-4, the bottom plate 1-1 Side plates 1-2 are fixedly connected to the front and rear sides of the base plate 1-1, support plates 1-3 are fixed to the left and right sides of the base plate 1-1, and T-shaped slide rails 1-3 are fixedly connected to the front and rear sides of the base plate 1-1. 4. The two T-shaped slide rails 1-4 are respectively located on the inner sides of the two side plates 1-2, and the front and rear sides of the bottom plate 1-1 are hinged with demoulding links 3 .

specific Embodiment approach 3

[0040] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the forming mold I2 includes a forming mold body I2-1, a closed connecting plate I2-2, a closed card slot 2-3, a closed baffle plate 2-4 and Adjust the support plate Ⅰ2-5, the upper end of the forming mold body Ⅰ2-1 is fixedly connected with the closed connection plate Ⅰ2-2, and the closed connection plate Ⅰ2-2 is provided with a plurality of closed card slots 2-3, and the closed connection plate Ⅰ2-2 The closed baffle 2-4 is fixedly connected, the lower end of the forming mold body I2-1 is fixedly connected with an adjusting support plate I2-5, and the front and rear sides of the forming mold body I2-1 are hinged with demoulding connecting rods 3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap