Transporting system for gypsum powder production

A conveying system and technology of gypsum powder, applied in the direction of conveyor, conveying bulk materials, transportation and packaging, etc., can solve the need for larger work site for gypsum powder transmission, the inability of chain plate elevator to reverse direction, and reduce the transfer speed of gypsum powder, etc. problems, to achieve the effect of convenient and efficient storage, avoid leakage, and avoid dust drifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

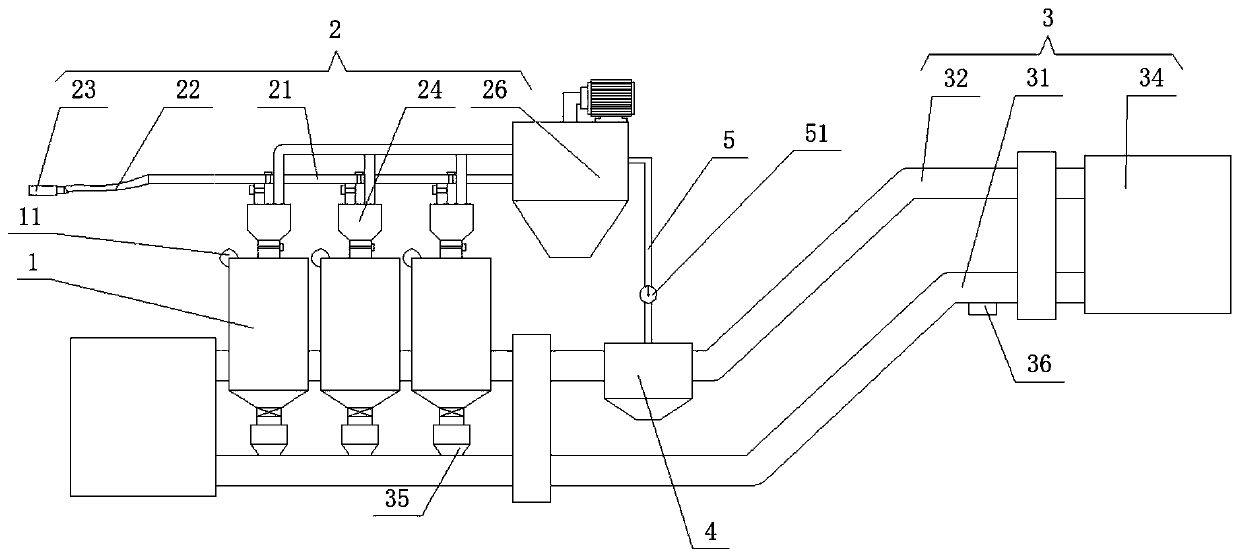

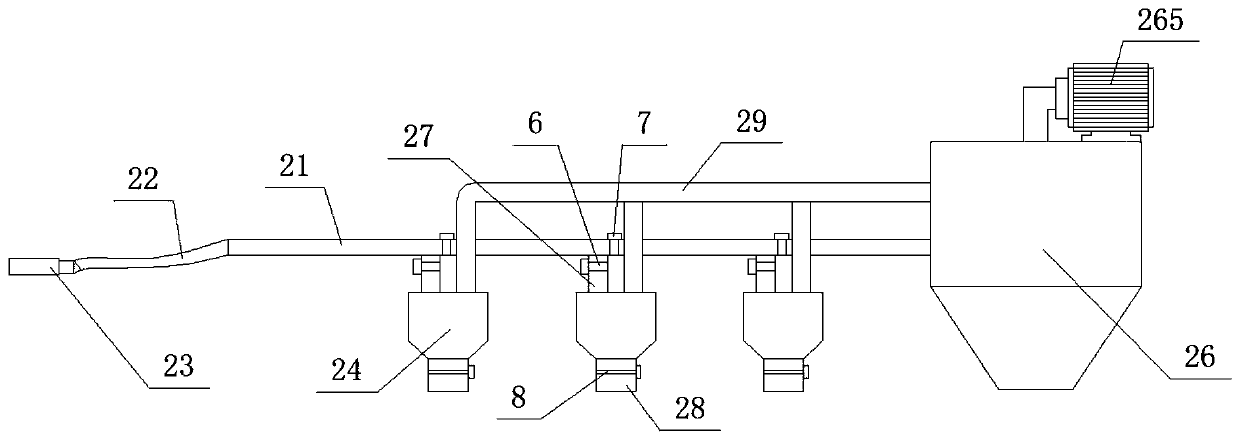

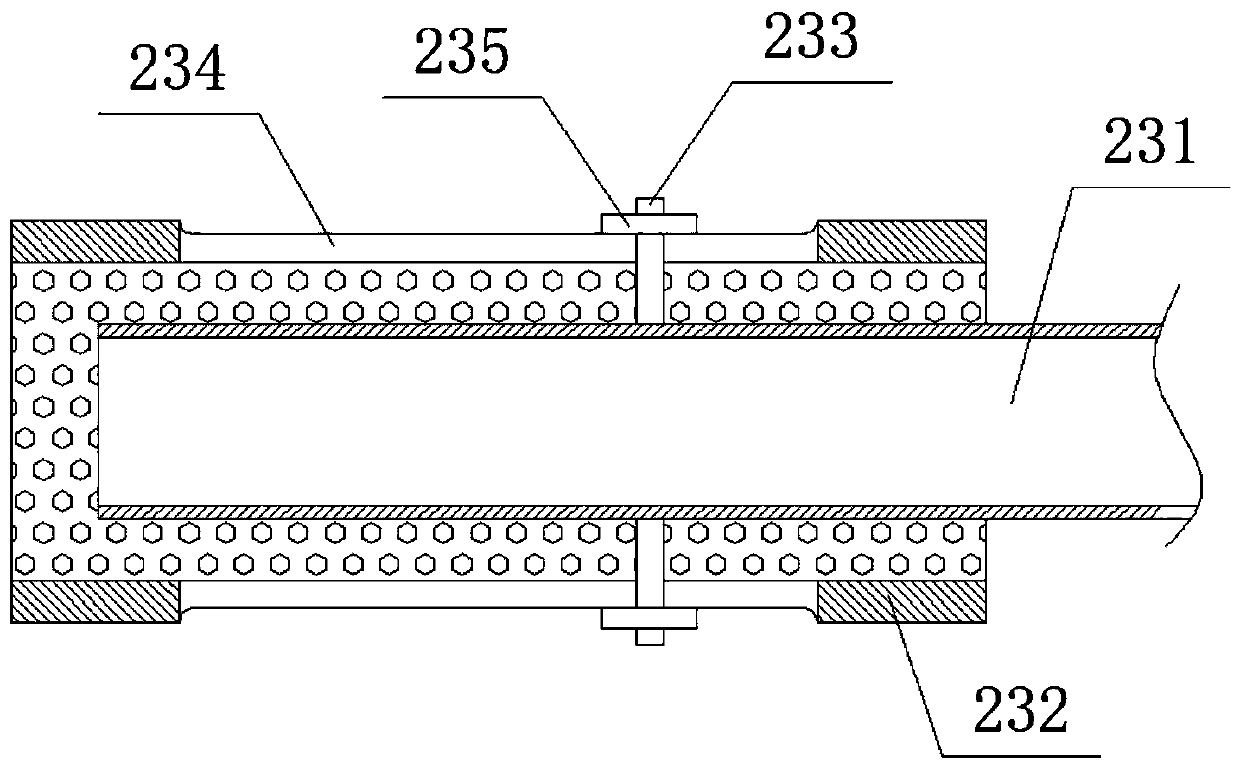

[0036] Such as Figure 1 to Figure 10 As shown, the conveying system for the production of gypsum powder provided in this embodiment includes a plurality of storage tanks 1 and a suction system 2 and a delivery system 3 which are respectively sealed and connected to the plurality of storage tanks 1, and the storage tanks 1 are equipped with There is a material level gauge 11 for detecting the height of the raw material, a valve 12 is provided at the bottom of the material storage tank 1, and the material suction system 2 includes a material distribution pipe 21, a hose 22, a suction head 23, a separator 24, an exhaust pipe 29, a separator cylinder 26 and fan 265, one end of the distribution pipe 21 is connected to the suction head 23 through the hose 22, and the other end is connected to the separation cylinder 26 for absorbing materials. separator 24, the top of each separator 24 is connected with the feed pipe 27 with the feed pipe 21, and the feed pipe 27 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com