Breast pump and breast pump assembly

A breast pump and component technology, which can be applied to breast pumps, suction devices, etc., can solve the problems of increasing use cost, energy consumption, and many parts, and achieve convenient alternate use and storage, reduce use cost, and simple and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

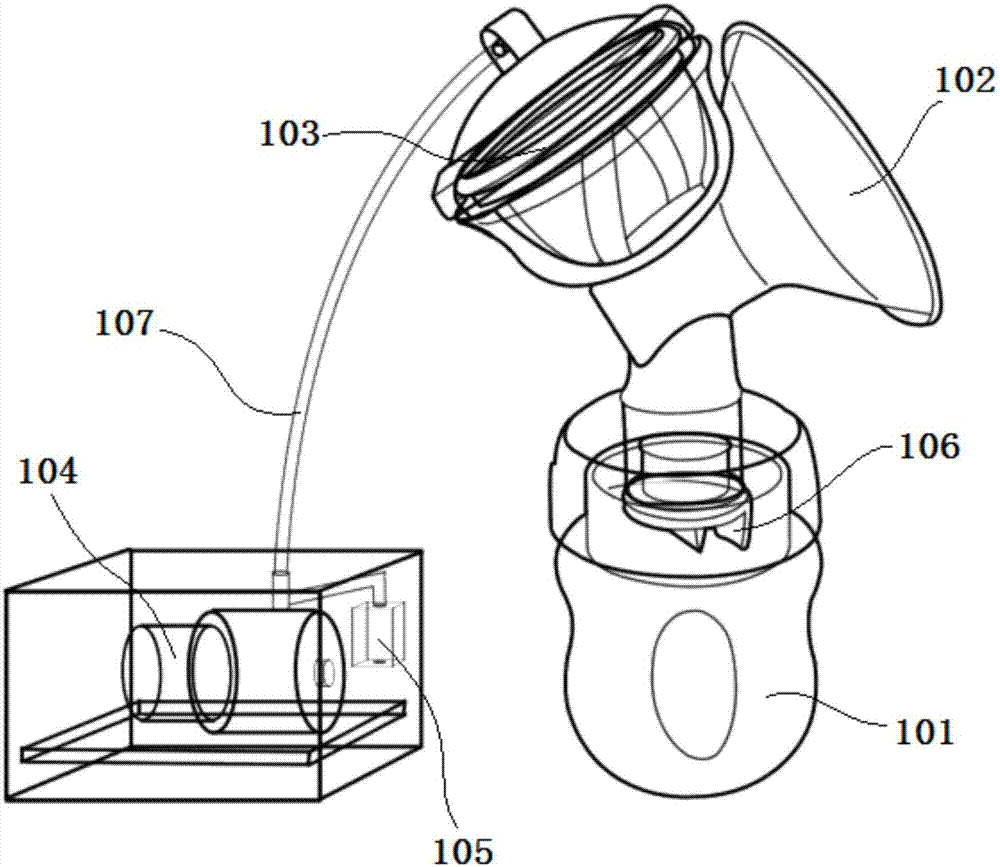

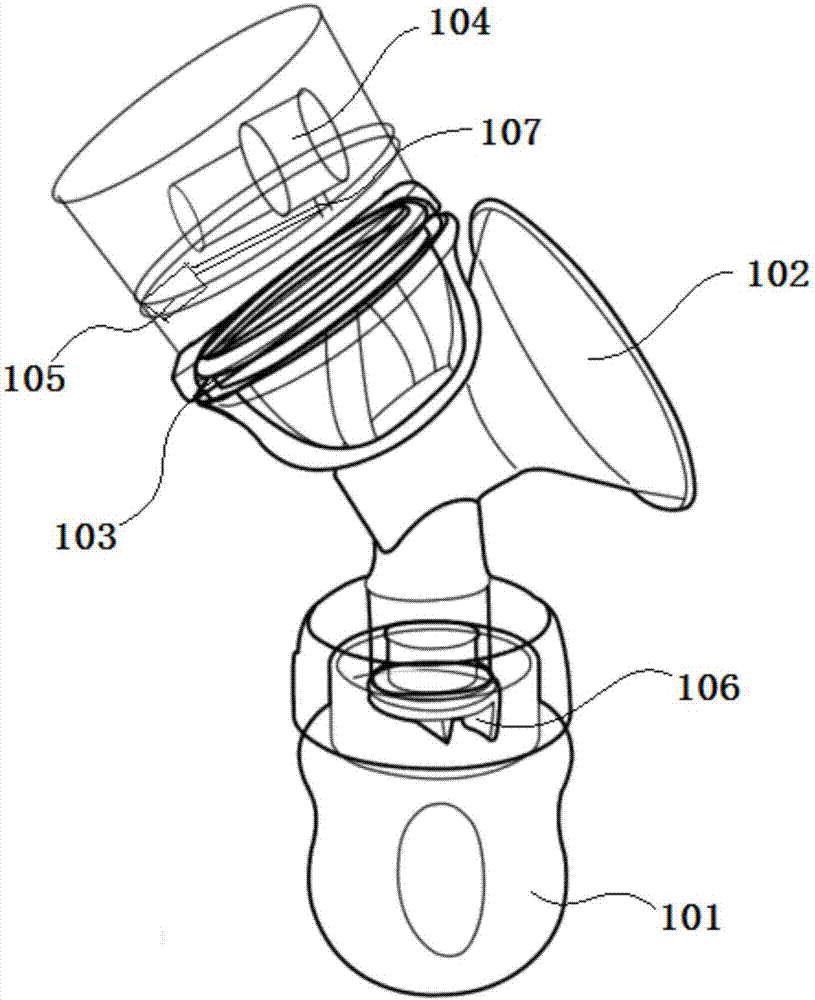

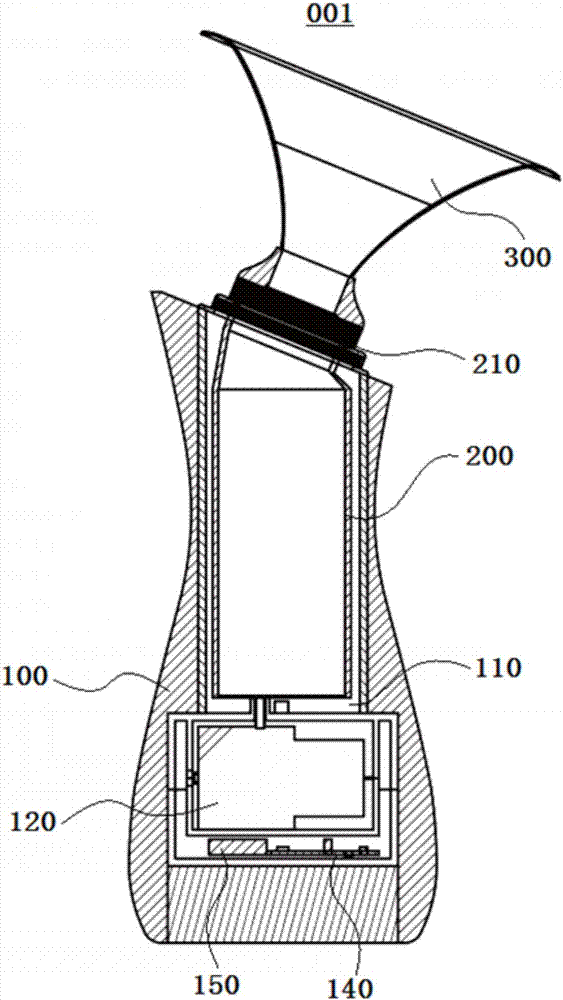

[0038] Please refer to image 3 , Figure 4 , Figure 5 and Figure 6 , the present embodiment provides a breast pump 001, which includes a housing 100, an expandable and contractable breast milk device 200, and a breast shield 300 communicating with the breast milk device 200. The cavity 110 and the air pump assembly for alternately pumping out or injecting air into the cavity 110 , the cavity 110 is closed when the milk holding device 200 is placed in the cavity 110 .

[0039] The breast pump 001 provided in this embodiment has the advantages of simple and compact structure, multiple functions, convenient assembly and disassembly, disinfection and use. When the breast pump 001 is sterilized, it is only necessary to take out the milk holding device 200 from the cavity 110, and sterilize the two components of the milk holding device 200 and the breast shield 300 before use; when using the breast pump 001, the user Place the breast milk device 200 in the cavity 110 to close...

Embodiment 2

[0048] Please refer to Figure 5 , Figure 6 , Figure 7 and Figure 8 , the present embodiment provides a breast pump assembly 003, which includes a breast pump 002 and a base 400, wherein the breast pump 002 includes a housing 100, an expandable and contractable milk holding device 200, and a suction pump connected to the milk holding device 200. Brassiere 300, the housing 100 is provided with a cavity 110 for accommodating the breast milk device 200 and an air pump assembly for alternately extracting or injecting air into the cavity 110, the air pump assembly includes an air pump 120 for extracting air from the cavity 110, and The solenoid valve 130 communicated with the cavity 110 closes the cavity 110 when the breastfeeding device 200 is placed in the cavity 110 . The milk holding device 200 is connected with a detachable adapter ring. When the milk holding device 200 is placed in the cavity 110, the adapter ring and the housing 100 are connected by threads to close th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com