Floating continuous crawler-type water surface oil absorption device

A crawler-type, oil-absorbing sponge technology, which is used in grease/oily substance/float removal devices, general water supply conservation, and open-air water surface cleaning, etc. The effect of reduced resource recovery, fast oil absorption, and high oil absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

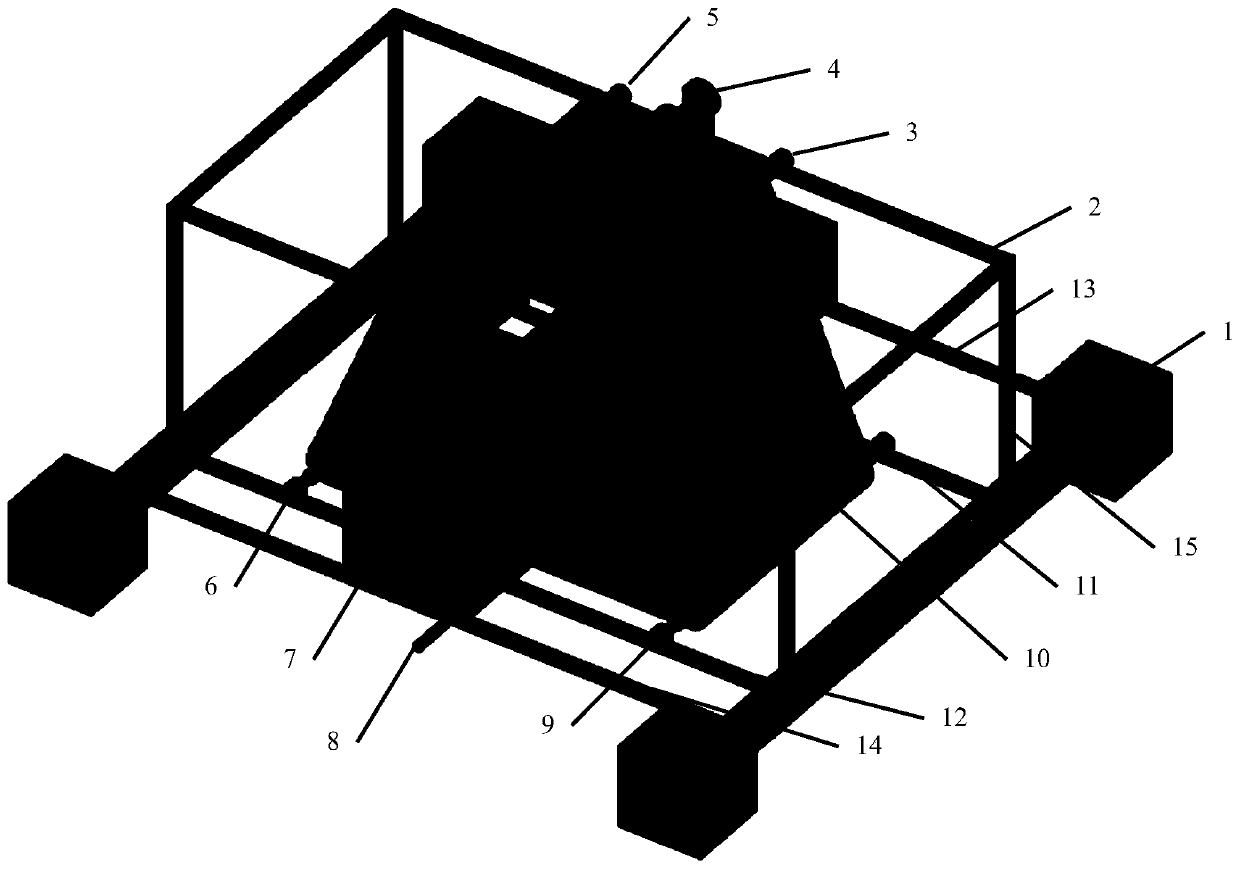

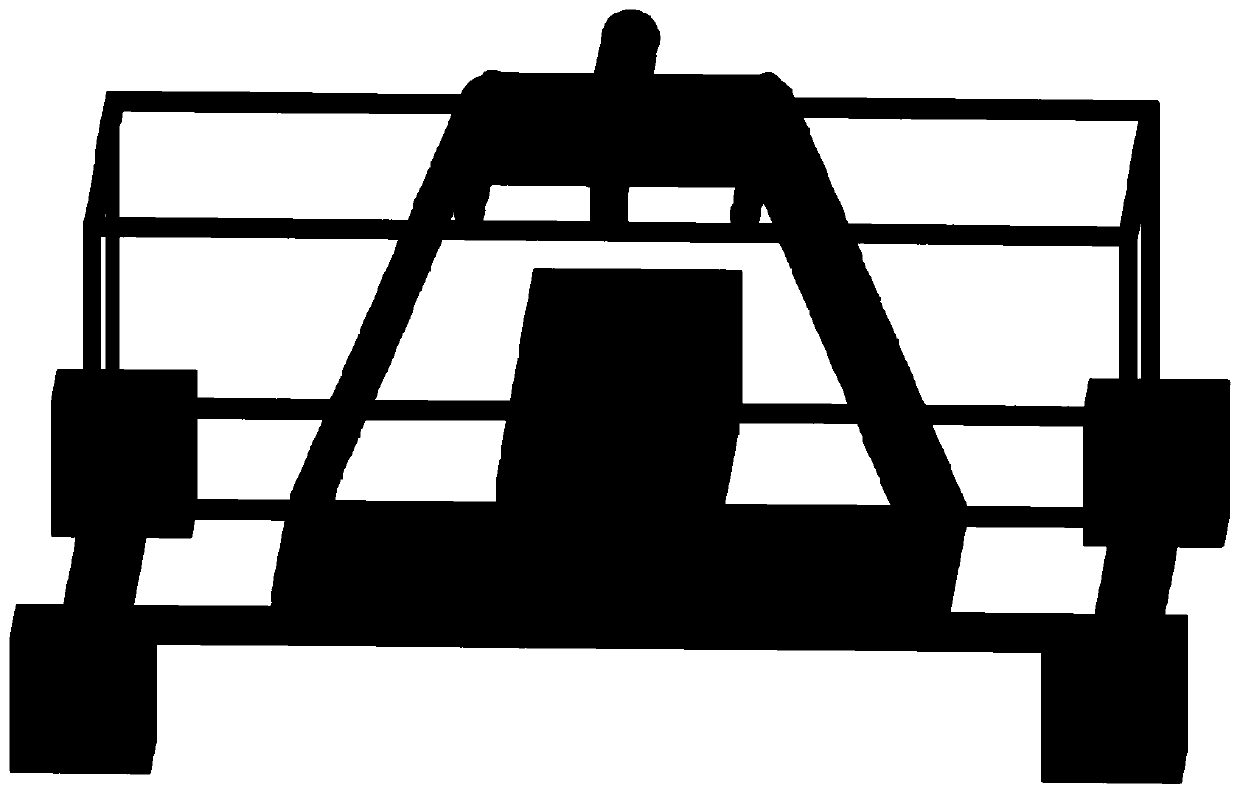

[0025] As shown in the figure, the floating continuous crawler-type water surface oil suction device of the present invention includes two elongated hollow buoys 1 on the left and right, a rectangular frame 2, an upper right driving roller 3, an opposing roller 4, an upper left driving roller 5, Lower left driven roller 6, oil tank 7, lower right driven roller 9, crawler type oil-absorbing sponge 10, driven roller support bar 11 / 12, oil tank support bar 13 / 14 and rectangular frame support bar 15, the rectangular frame passes 4 rectangular frame support rods 15 are fixed on two elongated hollow buoys, and the upper right driving drum 3 and the upper left driving drum 5 are fixedly arranged on the long side frame of the rectangular frame 2, while the upper right driving drum 3 and the upper left driving drum Between the rollers 5 there are fixedly arranged counter-roller rollers 4 that extrude crawler-type oil-absorbing sponges, and between the two elongated hollow buoys 2 there ...

Embodiment 2

[0027] As shown in the figure, the floating continuous crawler-type water surface oil suction device of the present invention includes two elongated hollow buoys 1 on the left and right, a rectangular frame 2, an upper right driving roller 3, an opposing roller 4, an upper left driving roller 5, Lower left driven roller 6, oil tank 7, lower right driven roller 9, crawler type oil-absorbing sponge 10, driven roller support bar 11 / 12, oil tank support bar 13 / 14 and rectangular frame support bar 15, the rectangular frame passes 4 rectangular frame support rods 15 are fixed on two elongated hollow buoys, and the upper right driving drum 3 and the upper left driving drum 5 are fixedly arranged on the long side frame of the rectangular frame 2, while the upper right driving drum 3 and the upper left driving drum Between the rollers 5 there are fixedly arranged counter-roller rollers 4 that extrude crawler-type oil-absorbing sponges, and between the two elongated hollow buoys 2 there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com