Film coating system and film coating method for milling tool

A technology of coating system and milling cutter, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of reduced efficiency of carburizing furnace, low efficiency of manual cleaning, etc., and achieves easy cleaning and convenient pick-and-place Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

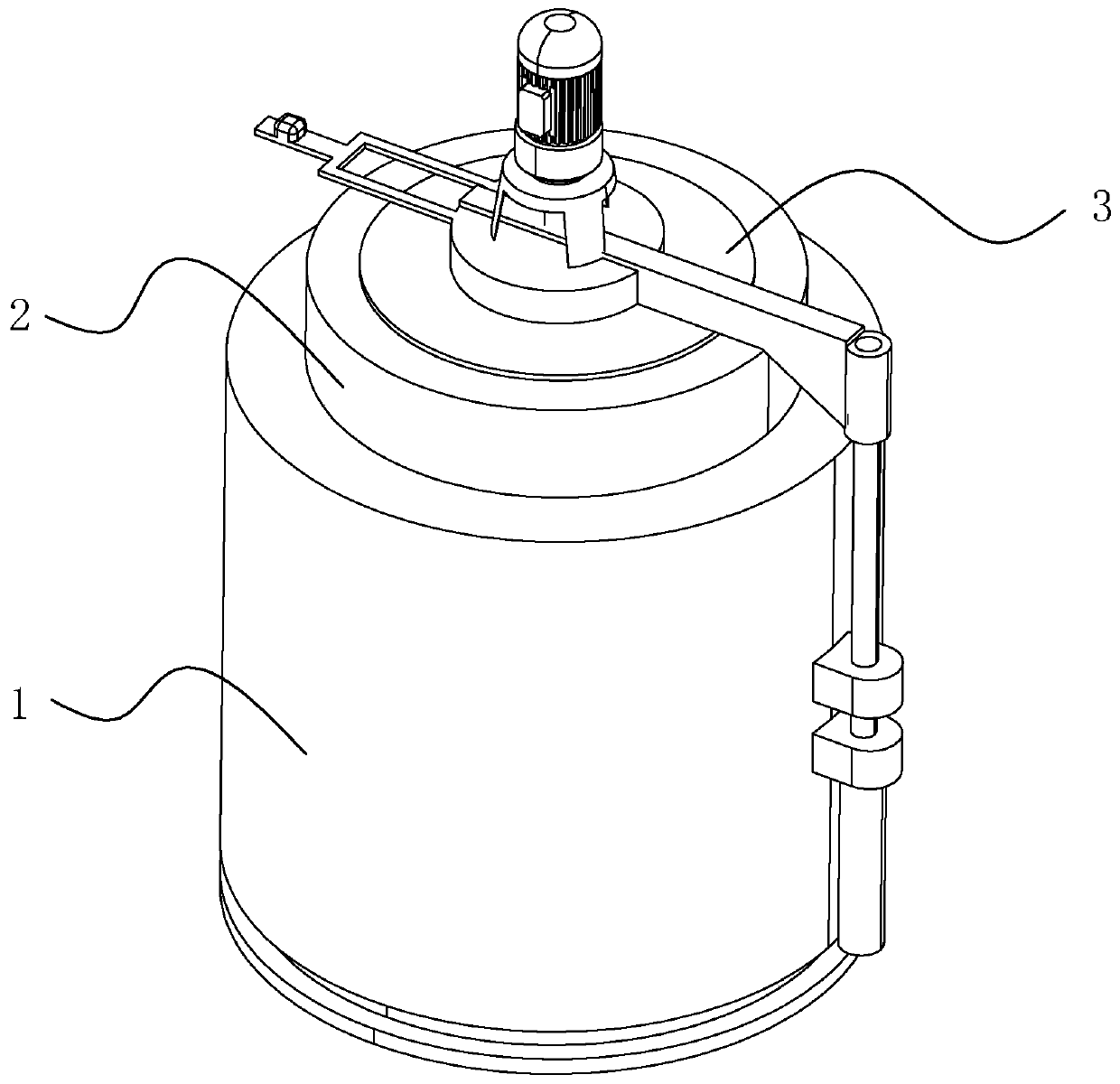

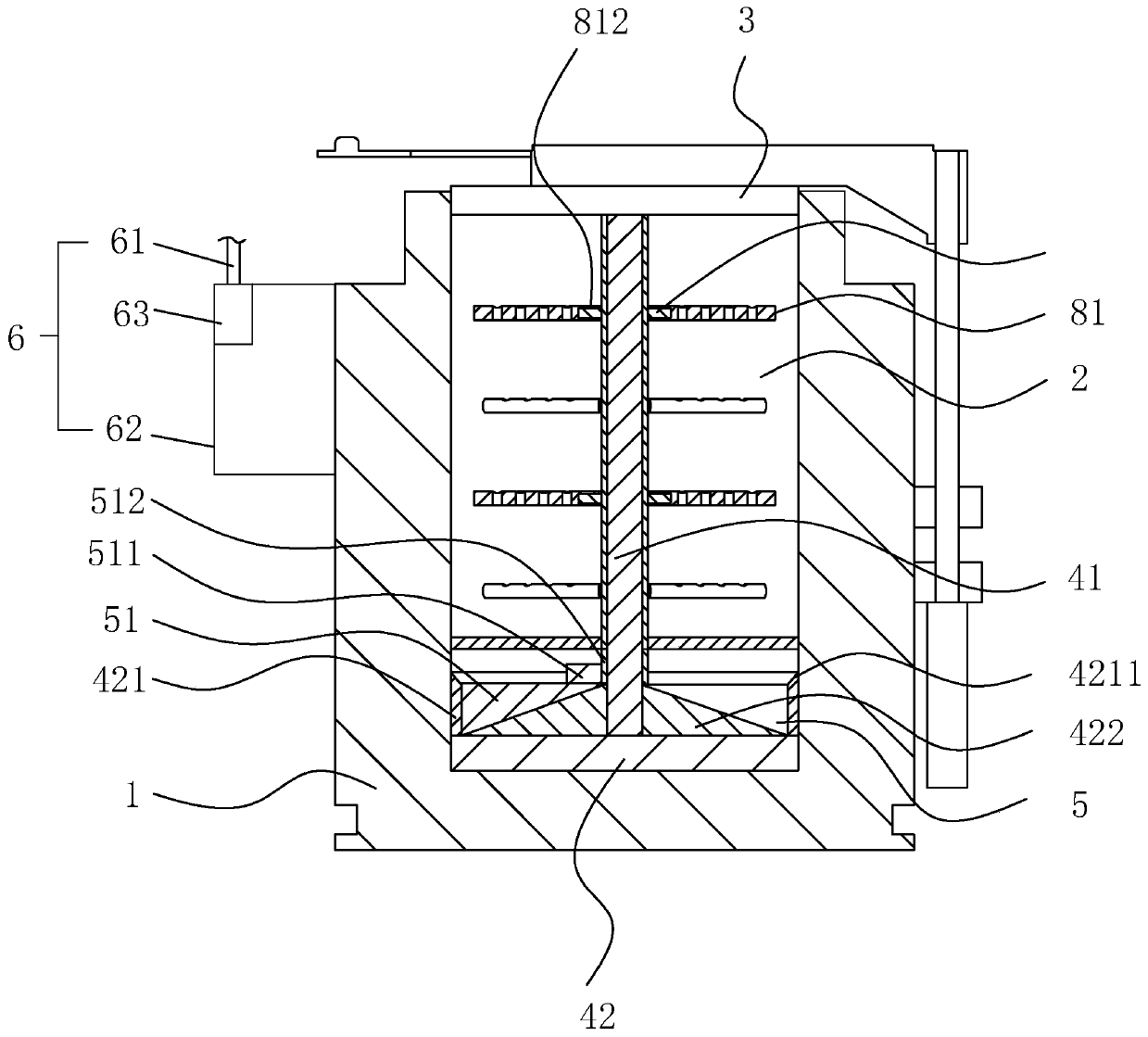

[0037] refer to figure 1 , which is a coating system for milling cutters disclosed in the present invention, includes a furnace body 1, a furnace hearth 2 and a furnace cover 3, the furnace hearth 2 is arranged inside the furnace body 1, and the furnace cover 3 is connected to the furnace body 1 by lifting and lowering a cylinder, The opening and closing of the furnace cover 3 is realized by the cylinder.

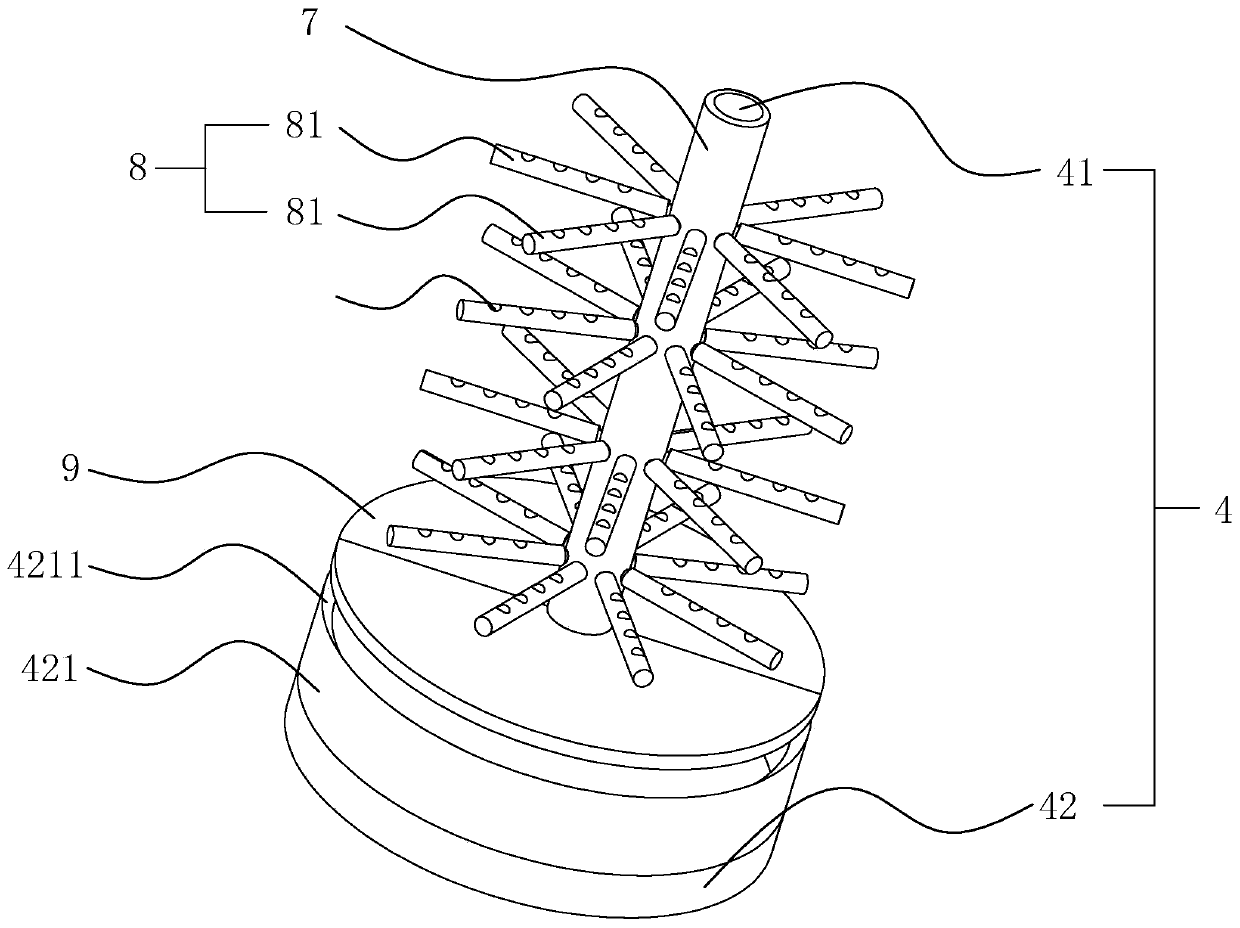

[0038] refer to figure 1 with figure 2 , the furnace 2 is provided with a carbon black removal device 4, the carbon black removal device 4 includes a support column 41 and a scraper plate 42, and the support column 41 is vertically welded on the side of the furnace cover 3 facing the direction of the furnace 2, which is far away from the furnace cover 3 direction One end of the scraper plate 42 is welded, and the scraper plate 42 is circular, and the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap