Spring motor with inspection function and inspection method

A motor and functional technology, applied in the engine application environment, spring motor inspection field, can solve the problems of not being able to confirm the status and authenticity of the inspection in time, whether it is completed or not, and consume a lot of manpower, etc., to reduce the inspection time, Reduce the intensity of manpower work and reduce the effect of dismantling and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

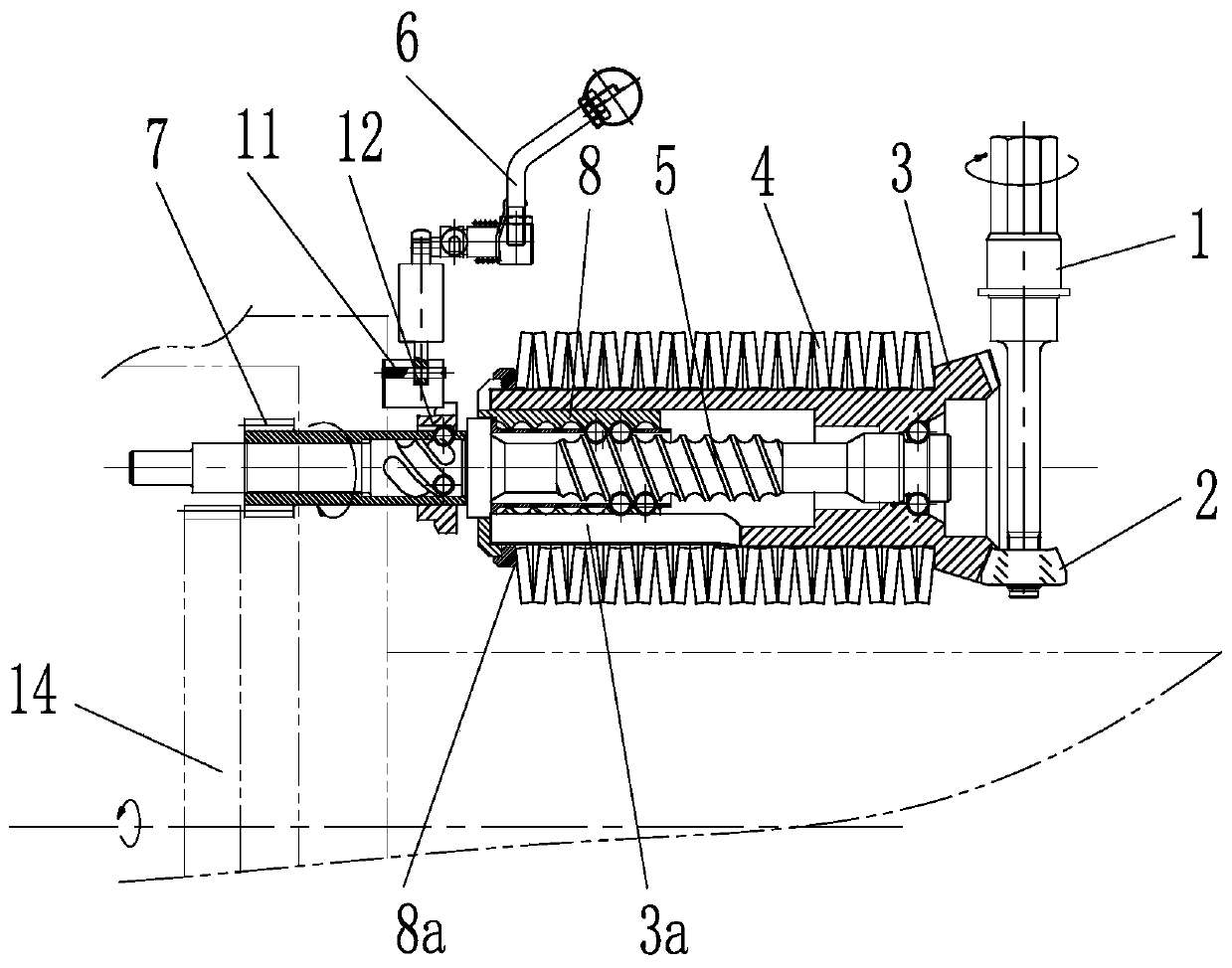

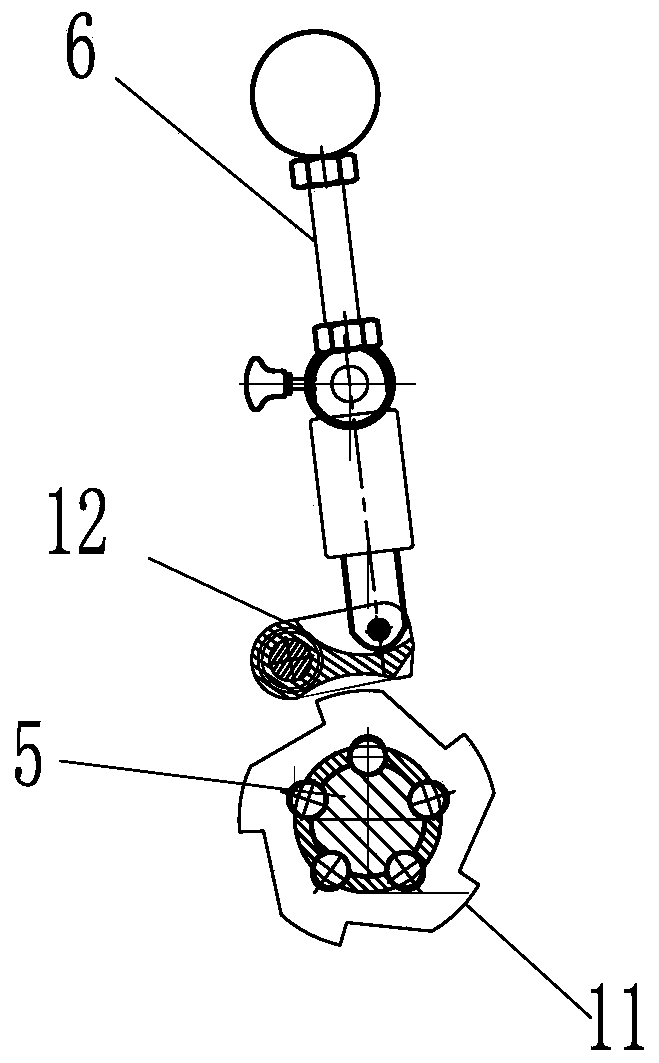

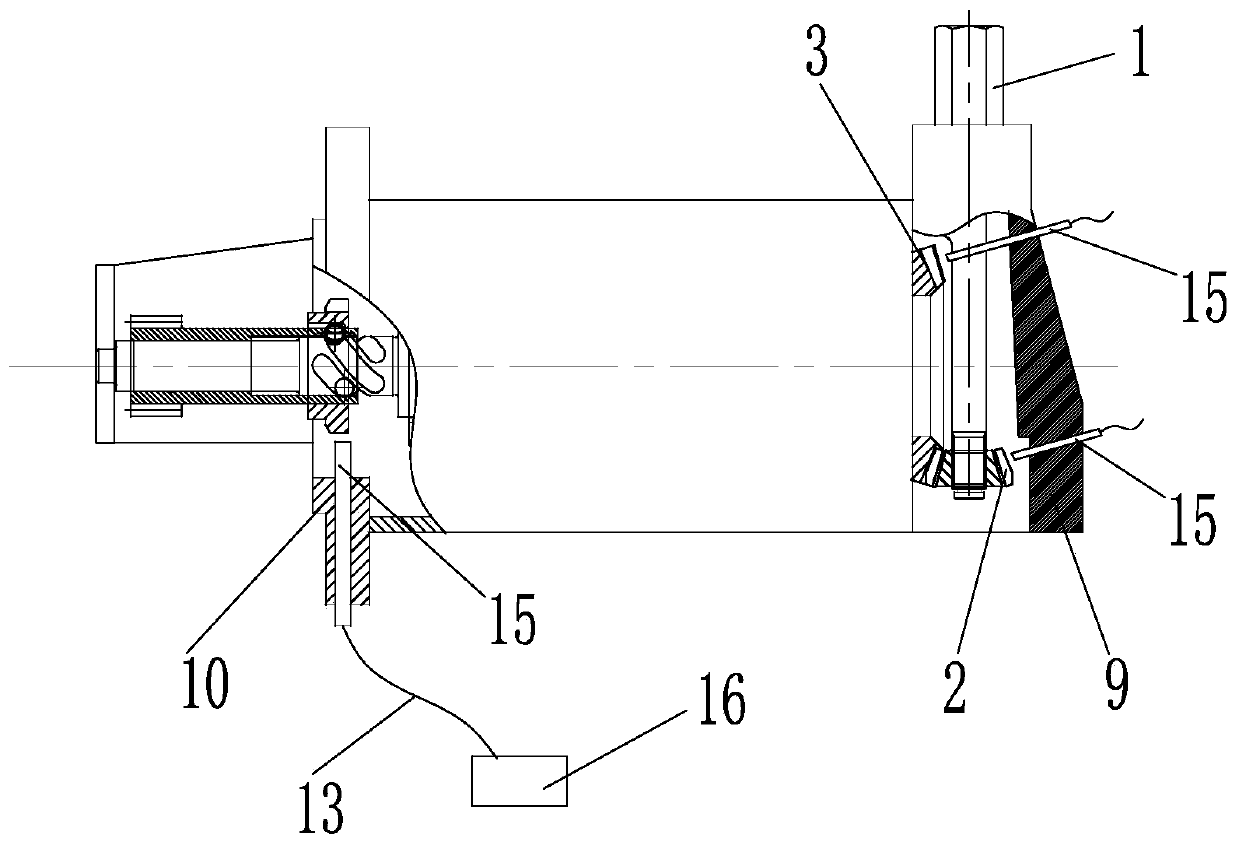

[0021] combine figure 1 , figure 2 The spring motor A shown is a spring motor with mature technology, mainly composed of a disc drive shaft 1, a disc drive gear 2, a drive gear 3, a spring 4, a main shaft 5, a release mechanism 6, a flywheel drive gear 7, a screw sleeve 8, front cover 9, rear cover 10, ratchet 11, ratchet block 12 etc. are formed. The screw sleeve 8 and the main shaft 5 constitute a screw nut pair. The left section of the drive gear 3 is provided with a fork groove 3a, and the screw sleeve 8 is provided with a circumferential shoulder 8a, which passes through the fork groove 3a and is connected to the screw sleeve 8, and the left end of the spring 4 is pressed against the ring shaft. on the shoulder 8a. When the driving gear 3 rotates, the screw sleeve 8 rotates together with the driving gear 3 under the action of the fork groove 3a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com