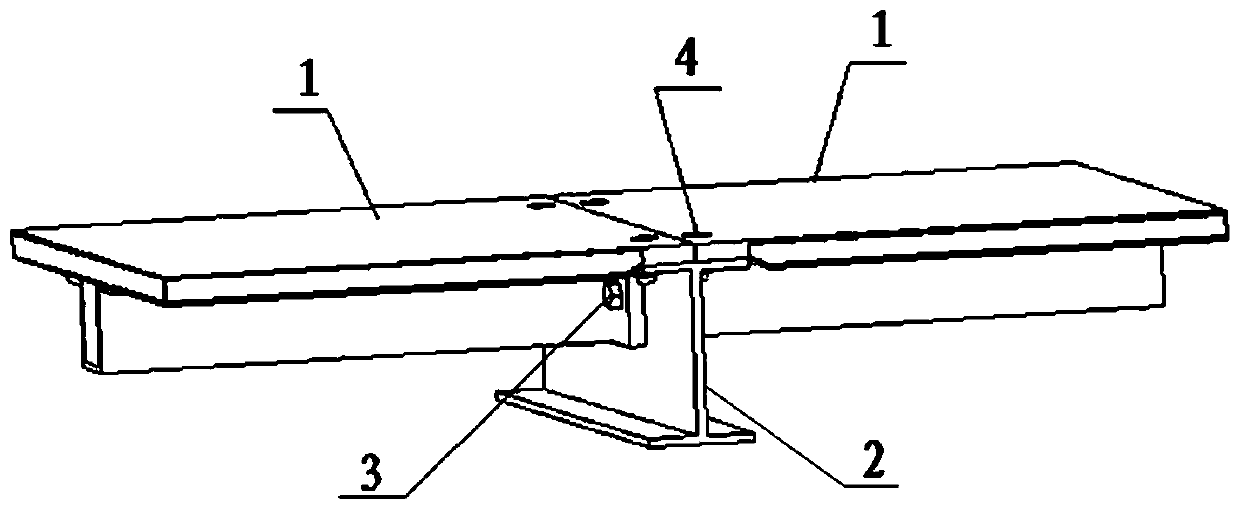

Combined connecting structure of reinforced composite material and metal material

A composite material and metal material technology, applied in the field of connection and assembly of dissimilar materials, can solve problems such as low load transfer efficiency, joint damage, and uncoordinated deformation, and achieve high load transfer efficiency, improved strength and stiffness, and deformation coordination. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

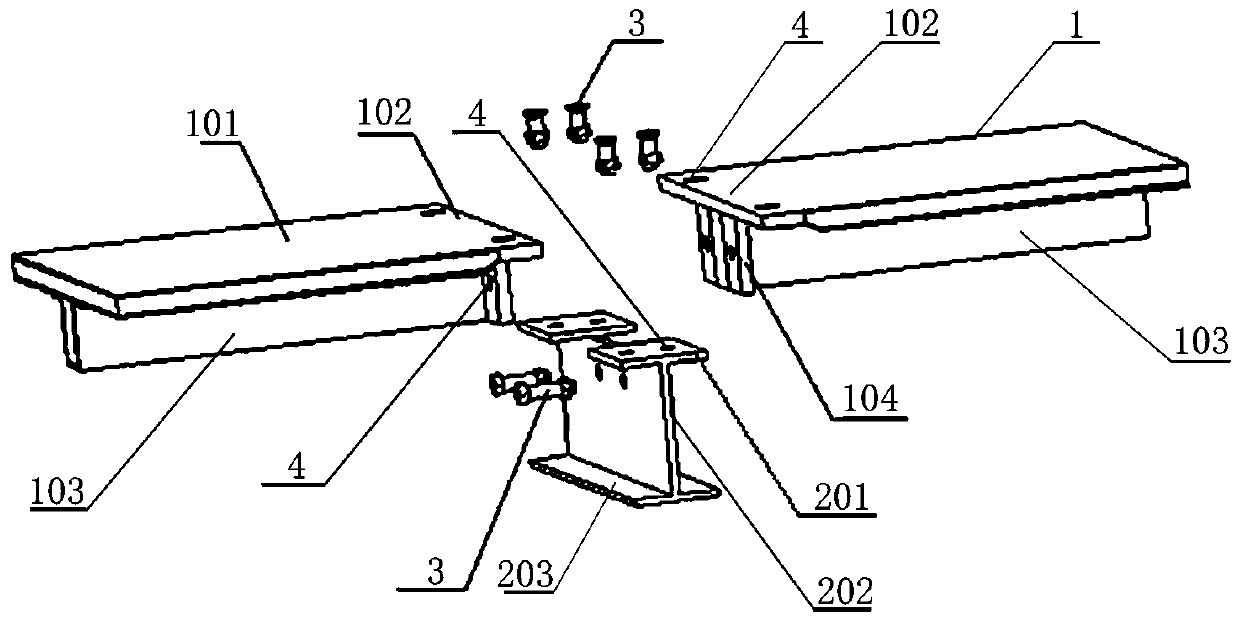

Embodiment 1

[0040] combined with figure 2, the metal material component in this embodiment adopts Q235 hull steel, the shape of the longitudinal section is "I" structure, the face plate and rib of the reinforced composite material component are sandwich composite materials, and the connecting joints and ear plates are composite material laminates Among them, the composite material of the surface layer of the panel and the rib, as well as the composite material of the connecting joint and the ear plate are all made of E glass fiber / vinyl resin, and the sandwich core material of the panel and the rib are made of H80 foam. The entire reinforced composite component is integrally formed using a vacuum assisted (VARI) forming process. The thickness of the connecting joint is obtained according to the size of the load, and the length of the connecting joint is required to be greater than 4 times the diameter of the connecting bolt, and is required to be greater than half of the width of the hor...

Embodiment 2

[0046] combined with figure 2 , the metal material components in this embodiment are made of Q235 hull steel, the shape of the longitudinal section is "I" type structure, the panels, connecting joints and ear plates of the reinforced composite material components are all composite material laminates, and the reinforcing ribs are sandwich composite Material reinforcement ribs, among which, the composite materials of panels, connecting joints and ear plates, and the surface layer composite materials of the reinforcement ribs are all made of E glass fiber / vinyl resin, and the sandwich core material of the reinforcement ribs is made of H200 foam. The entire reinforced composite component is integrally formed using a vacuum assisted (VARI) forming process. The thickness of the connecting joint is obtained according to the size of the load, and the length of the connecting joint is required to be greater than 4 times the diameter of the connecting bolt, and is required to be greate...

Embodiment 3

[0052] combined with figure 2 , the metal material components in this embodiment are made of Q235 hull steel, and the shape of the longitudinal section is "I" type structure. Using E-glass / vinyl resin, the entire reinforced composite component is integrally formed using a vacuum-assisted (VARI) molding process. The thickness of the connecting joint is obtained according to the size of the load, and the length of the connecting joint is required to be greater than 4 times the diameter of the connecting bolt, and is required to be greater than half of the width of the horizontal plate. The transition angle between the joint and the panel is 0°. The lug height is the same as the rib height.

[0053] The horizontal plate in the metal material component is slotted according to the position and size of the rib and the lug plate to ensure that the lug plate is closely connected with the vertical plate of the "I" structure. Countersunk bolts are used to connect the connection join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com