A two-degree-of-freedom and three-degree-of-freedom convertible ball joint structure

A degree of freedom and ball joint technology, applied in the field of ball joints, can solve the problems of inability to achieve stable control of the horizontal plane of the screen, inability to achieve spatial positioning control, etc., and achieve the effects of simple structure, strong locking force, and good dust-proof sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

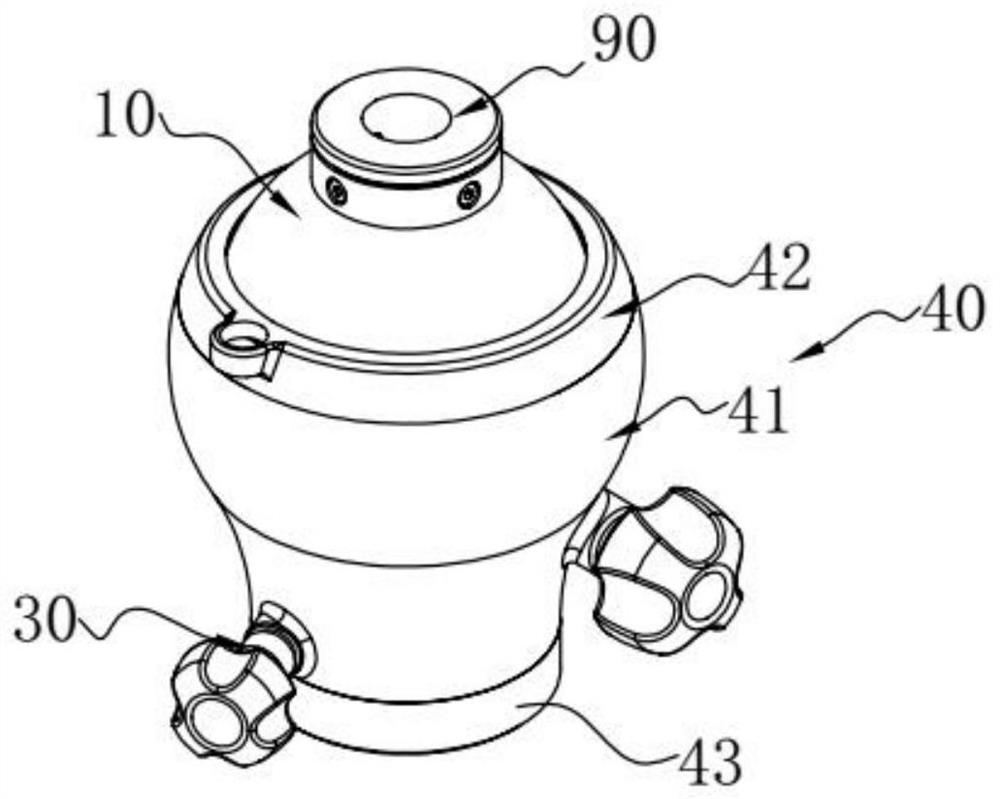

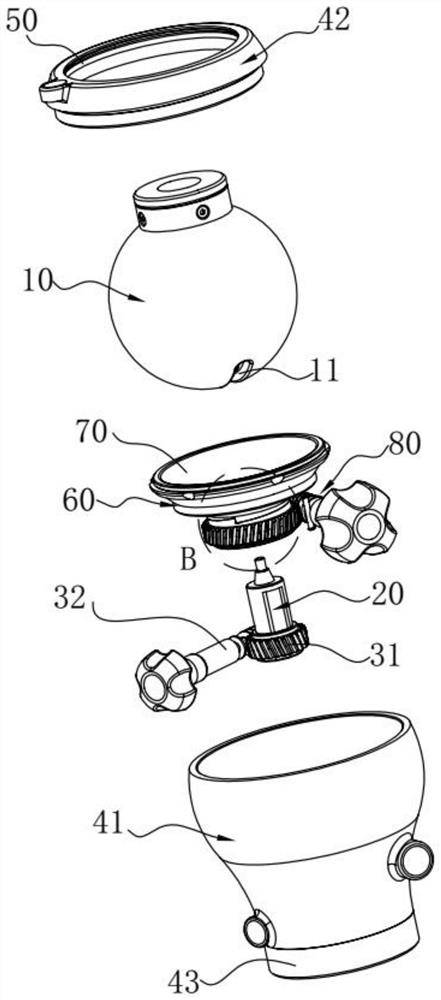

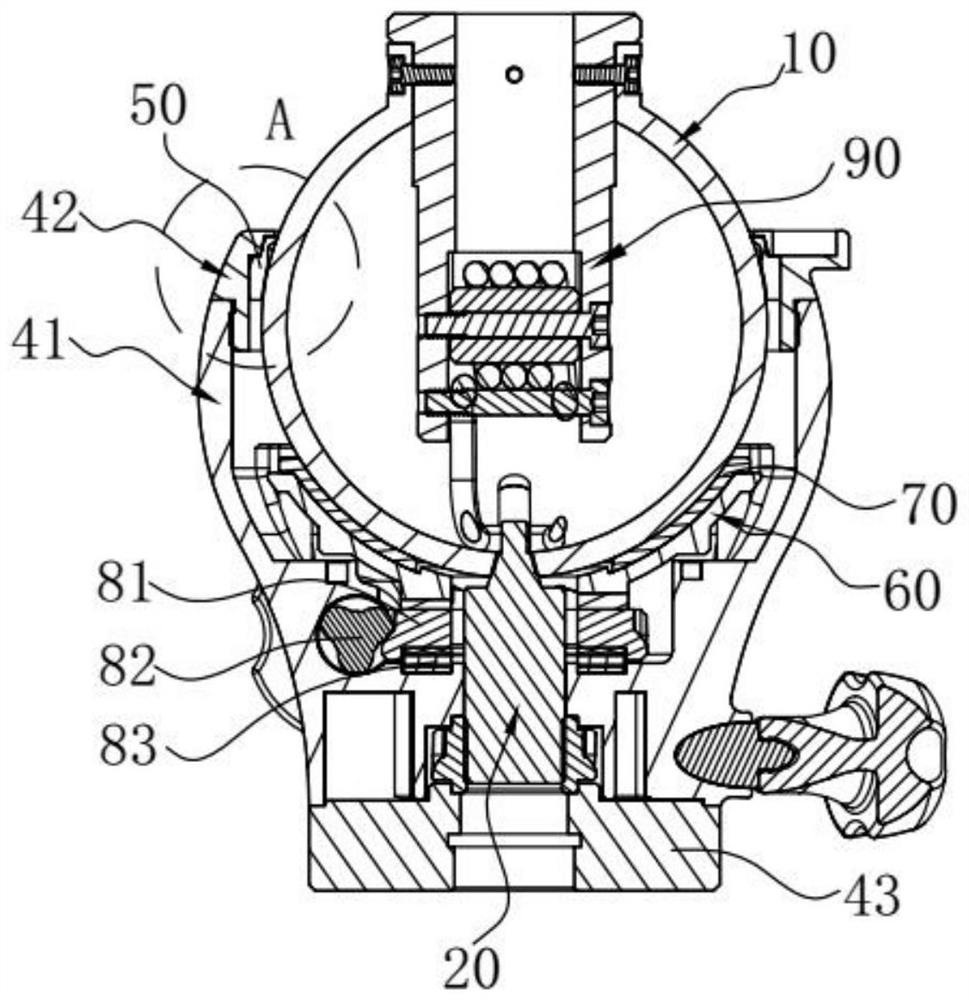

[0039] Such as Figure 1 to Figure 19 As shown, the present invention provides a two-degree-of-freedom and three-degree-of-freedom convertible ball joint structure, including: an outer shell 40 with an accommodation cavity; located in the accommodation cavity of the outer shell 40 and can be placed in the The hollow sphere 10 rotating in the accommodating cavity, such as Figure 8 and Figure 9 As shown, more than half of the spherical surface of the sphere 10 is located in the accommodating cavity of the outer shell 40, that is, most of the sphere 10 is located in the accommodating cavity of the outer shell 40, and the lower part of the sphere 10 is On the hemispherical surface, a trough 11 with a center plane of symmetry positioned on the vertical center plane of the sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com