Raw material draining equipment for processing of self-heating food

A food processing and raw material technology, which is applied in the field of raw material draining equipment for self-heating food processing, can solve the problems of fruit and vegetable corruption, slow draining speed, and affect the quality of food processing, so as to prevent corruption, speed up draining, and speed up The effect of air movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

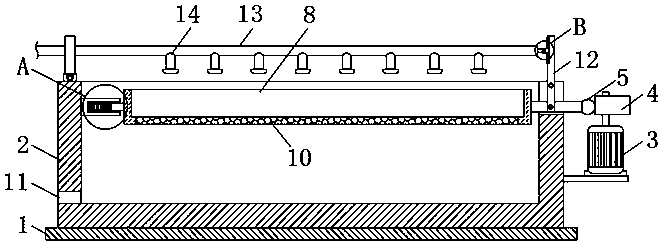

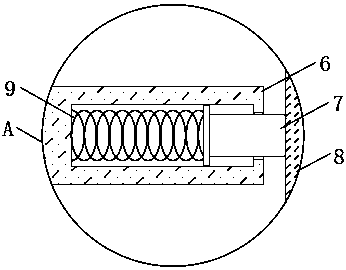

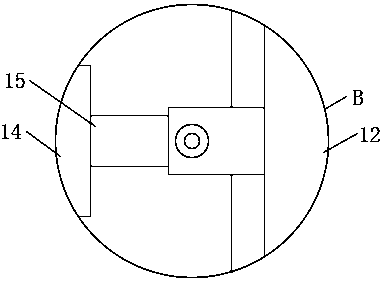

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0017] refer to Figure 1-3 , a self-heating food processing raw material draining equipment, including a bottom plate 1, a box body 2 with an open upper end is installed on the bottom plate 1, a drive motor 3 and a plurality of reciprocating mechanisms are respectively arranged on the side wall and the inner wall of the box body 2, The output shaft of the driving motor is provided with a transmission mechanism, and a hopper 8 is installed between the transmission mechanism and a plurality of reciprocating mechanisms. The lower end of the hopper 8 is equipped with a filter screen 10, and the filter screen 10 is made of resin plastic material. To prevent the filter screen 10 from rusting, and to prevent the filter screen 10 from damaging the raw materials, the output end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com