Heat exchanger for pure electric automobile cooling system

A pure electric vehicle and cooling system technology, which is applied in the field of heat exchangers used in the cooling system of pure electric vehicles, can solve the problems of waste, heat exchanger copper tubes that cannot be replaced, and the service life of the device is easily affected by copper tubes, etc., so as to achieve easy replacement , the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

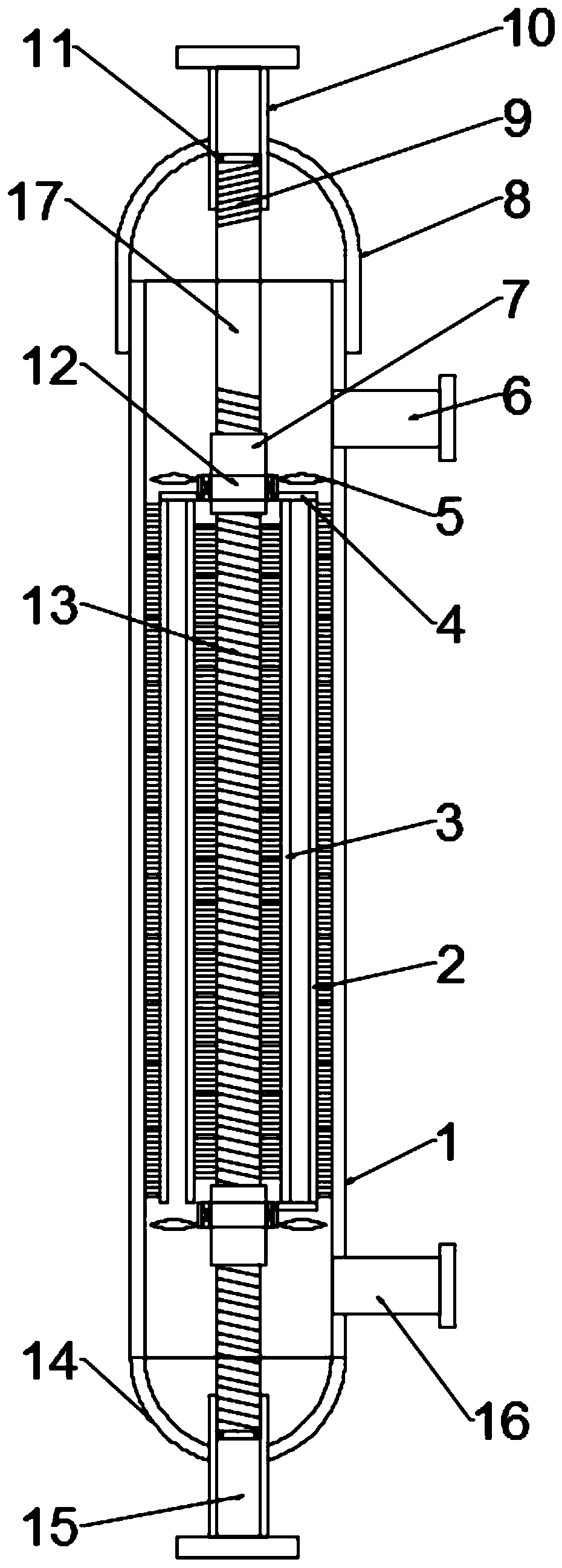

[0017] see figure 1 , in an embodiment of the present invention, a heat exchanger for a pure electric vehicle cooling system includes a cylinder body 1, an upper head 8, a lower head 14 and a copper tube 17, and the top and bottom of the cylinder body 1 are respectively provided with an upper The head 8 and the lower head 14, the upper head 8 is provided with a heat medium inlet pipe 11, the lower head 14 is provided with a heat medium outlet pipe 15, and the upper and lower parts of one side of the cylinder body 1 are respectively provided with a refrigerant outlet pipe 6 And the refrigerant inlet pipe 16, the copper pipe 17 is connected between the heat medium inlet pipe 11 and the heat medium outlet pipe 15 in the cylinder 1, the lower head 14 is welded and fixed to the bottom of the cylinder 1, and the upper head 8 It is threadedly connected with the top of the cylinder 1, and the outer wall of the top of the copper pipe 17 is provided with a first threaded section 9, and ...

Embodiment 2

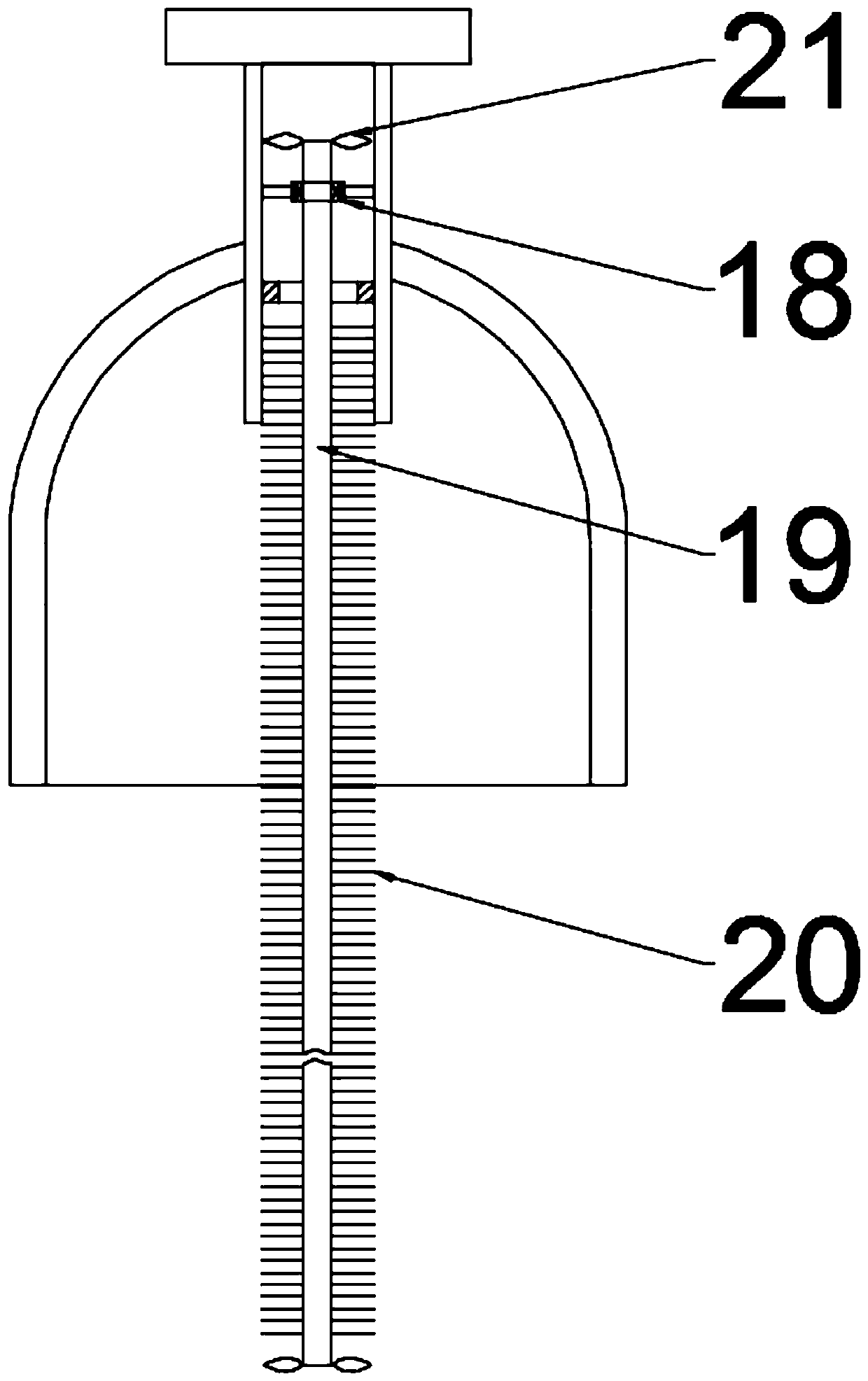

[0019] see figure 2 , The difference between this embodiment and Embodiment 1 is that it also includes a second descaling mechanism, and the second descaling mechanism includes a rotating shaft 19, a second propeller blade 21 and a third brush bar 20, and the rotating shaft 19 Installed in the heat medium inlet pipe 10 through the bearing and the mounting plate 18, the mounting plate 18 is welded and fixed with the heat medium inlet pipe 10 through the support rod, and the third brush bar 20 is installed on the two side walls of the rotating shaft 20, and the two ends of the rotating shaft 19 A plurality of second propeller blades 21 are mounted equidistantly through screw rings. When the heat medium enters the copper pipe 17 from the heat medium inlet pipe 10 and then flows out from the heat medium outlet pipe 15, the second propeller blades 21 drive the rotating shaft 19 to rotate. , the rotating shaft 19 drives the third brush bar 20 to rotate to clean the scale on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com