A new wear-resistant testing device

A wear resistance test, a new type of technology, applied in the field of textile belts, can solve the problem of insufficient persuasiveness and reliability of the wear resistance and wear resistance of textile belts, unable to effectively simulate the wear conditions and scenarios of textile belts, and the quality of textile belts The detection does not have enough persuasion and other problems, so as to achieve the effect of accurate and reliable test results, simple structure, high persuasion and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

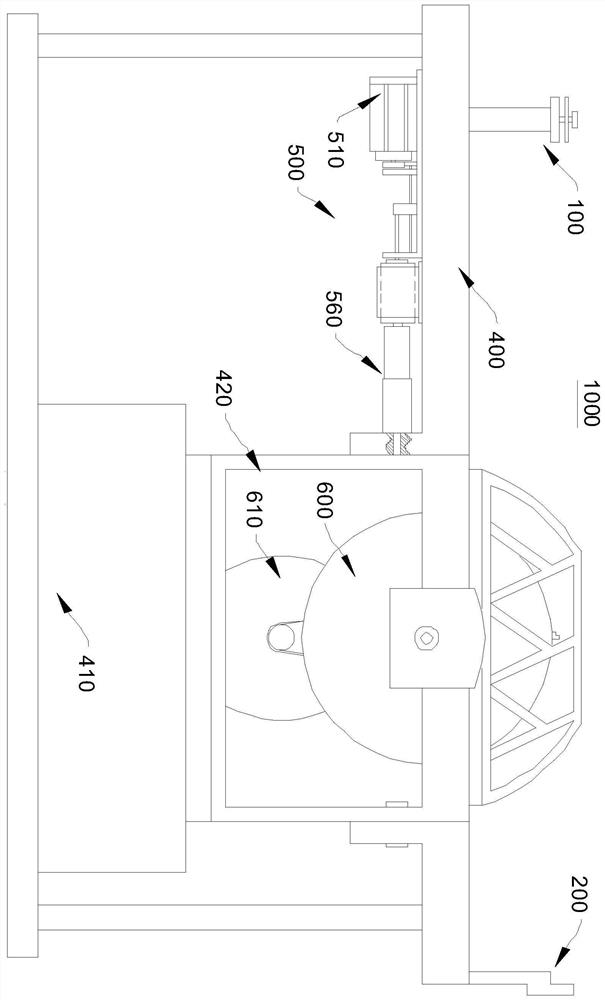

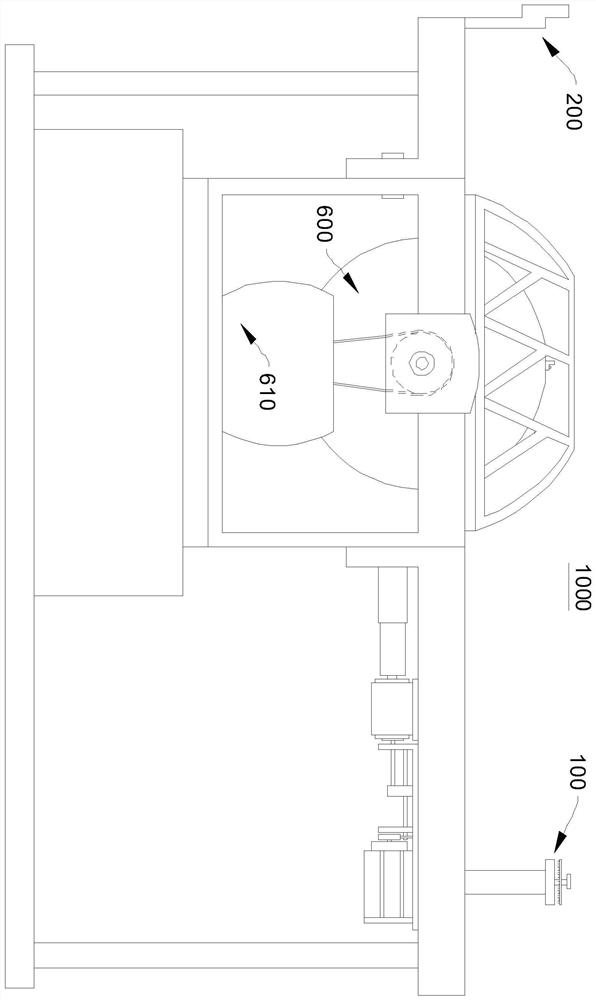

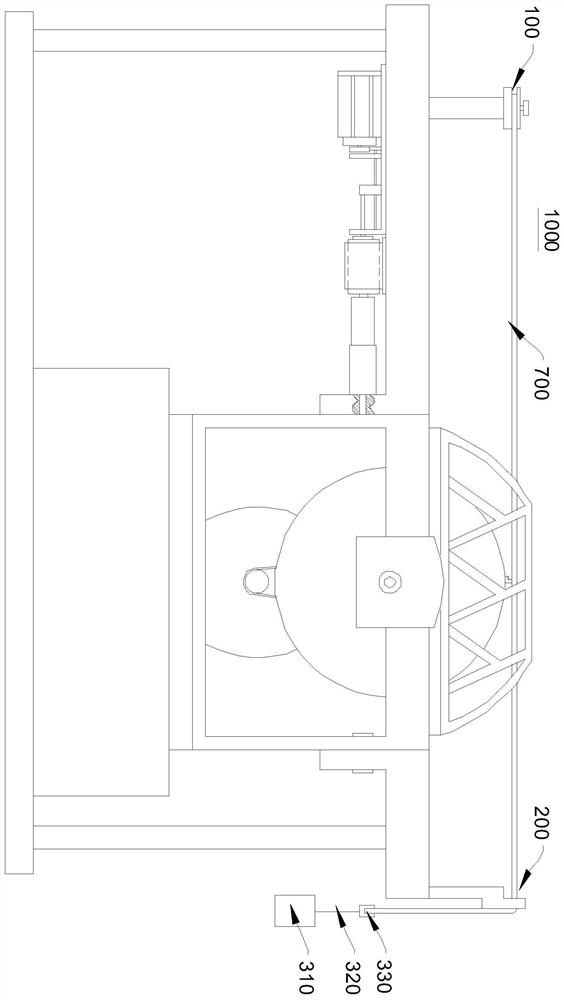

[0030] Please refer to Figure 1~3 , the present embodiment provides a novel wear-resistant testing device 1000 , and the novel wear-resistant testing device 1000 includes: a fixing part 100 , a supporting part 200 , a counterweight and a base 400 .

[0031] Both the fixing part 100 and the supporting part 200 are erected on the base 400, the fixing part 100 has a first connecting part for detachably connecting with one end of the textile belt 700, and the supporting part 200 has a strip-shaped through hole for the textile belt 700 to pass through , the counterweight has a second connecting portion for detachably connecting with the other end of the textile belt 700 .

[0032] The base 400 has a base 410 , and the top of the base 410 has an arc-shaped concave area 411 . The base body 400 is rotatably mounted with a swing base 420 and is driven by the first driver 500 to swing reciprocatingly. The swing base 420 is attached to the recessed area 411 . The swing base 420 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com