Automatic visual solidifying point determining device

A measuring device and testing device technology, which is applied in the investigation stage/state change, etc., can solve problems such as automatic instrument test errors, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

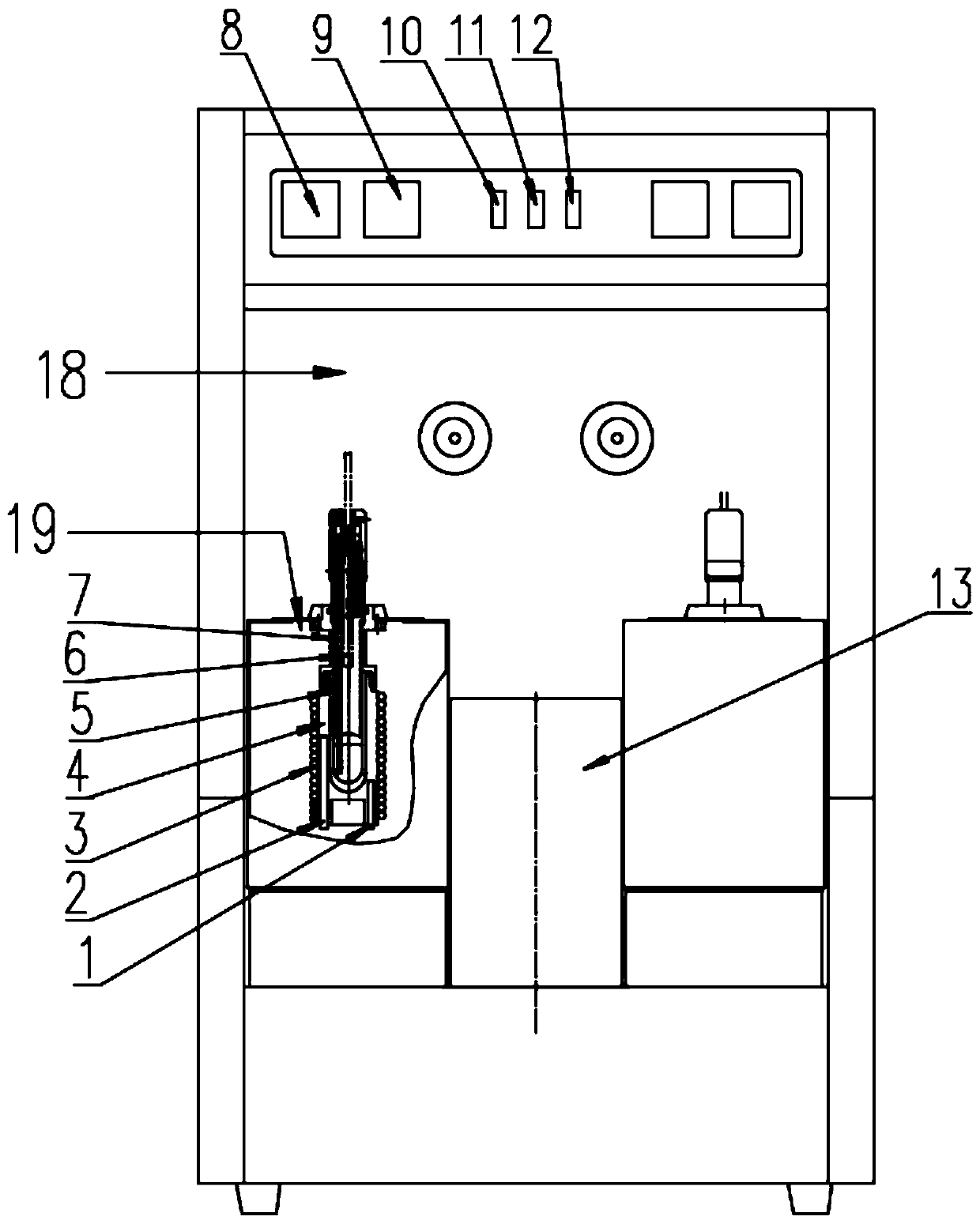

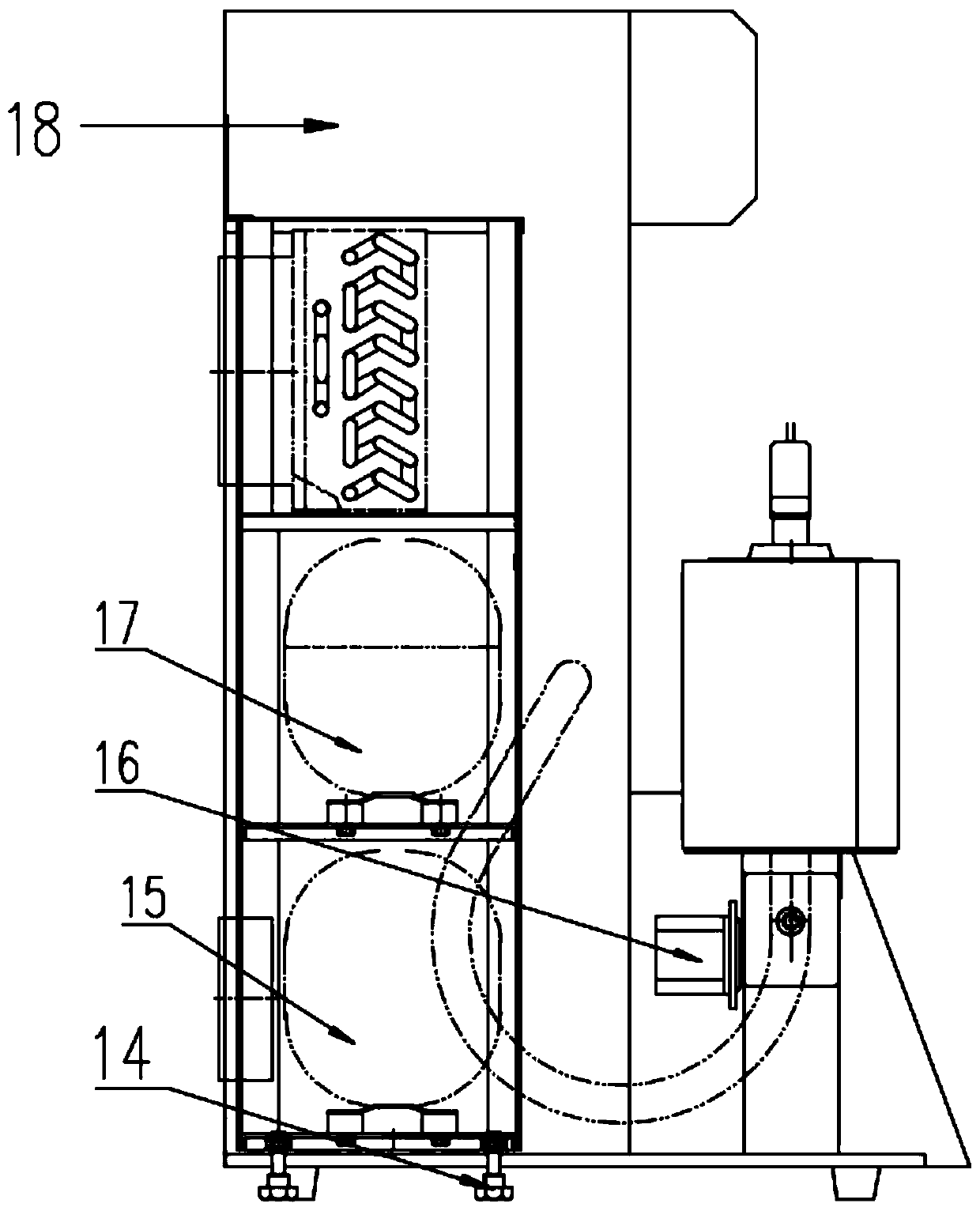

[0020] see Figure 1-2 , the present embodiment provides an automatic visual coagulation point determination device, including a device housing 18, a test device 19 and a stepper motor 16; the test device 19 is driven by a stepper motor 16 to tilt and return, and the stepper motor 16 is set Inside the device shell 18; the test device 19 is electrically connected to the computer on one side of the automatic visual coagulation point determination device, and the stepping motor 16 rotates to drive the test device 19 to tilt forward 45 degrees and return.

[0021] Described testing device 19 comprises cooling device, thermostat 2, special test tube 5 and visual sensor 6; Described visual sensor 6 is arranged in the special test tube 5, is used for real-time detection the situation of petroleum condensation in special test tube 5; The thermostat 2 and the cooling device are arranged on the periphery of the special test tube 5 to keep the internal temperature of the test tube 5 stab...

Embodiment 2

[0029] This embodiment is further improved on the basis of embodiment 1. The improvement is that: the bottom of the device housing 18 is provided with a plurality of shock-absorbing feet 14 to prevent the vibration of the equipment from causing errors in the detection results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com