A kind of hoisting centralized control system with one control and multiple

A centralized control system and centralized control technology, applied in the field of centralized control systems, can solve problems such as untimely summary of production reports, lack of elevator operators, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

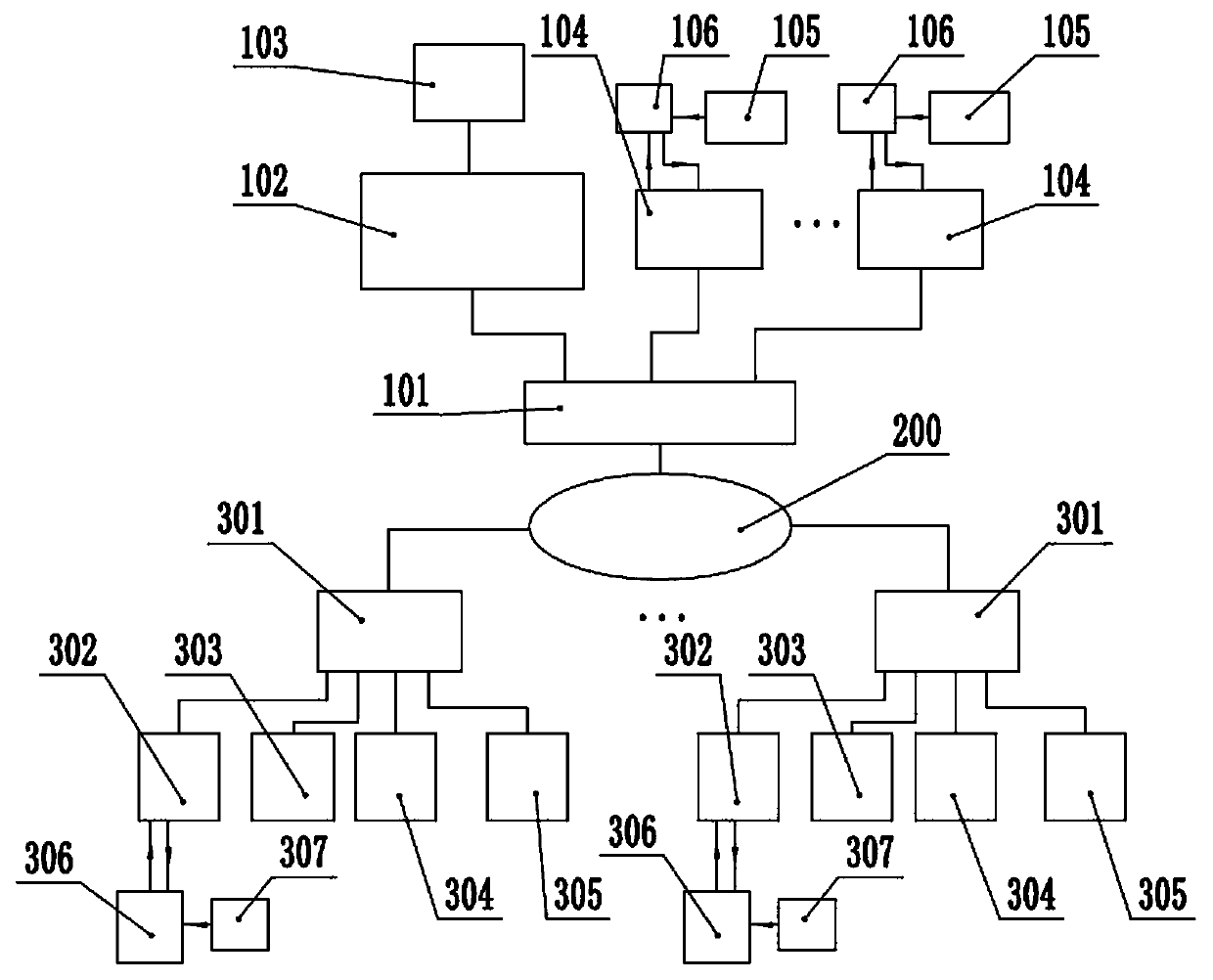

[0027] Such as figure 1 , a one-control and multiple hoist centralized control system, used to control multiple hoists on site.

[0028] There are on-site switches 301, on-site PLC302, on-site consoles, touch screens, and on-site host computers that correspond to the hoists one by one. Local switches 301 are connected. The local console and touch screen are used to set parameters, and the on-site host computer is used to display status information.

[0029] The switch has electrical ports and optical ports to realize mutual communication and network communication of connected devices. The local PLC302 also controls the motor controller 305 (converter, frequency converter) and other sub-stations through the Profibus-DP communication method, and realizes communication with each ore unloading station, ore loading station, and each middle section box thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com