A Robust Fault Diagnosis Method for Chemical Liquid Level Process Control System

A process control system and fault diagnosis technology, applied in the chemical industry, can solve problems such as easy to burn dry pot, overflow danger, steam with water, etc., achieve high sensitivity, ensure robustness, and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings.

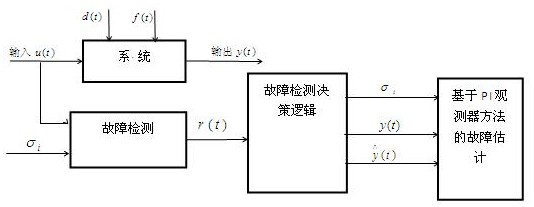

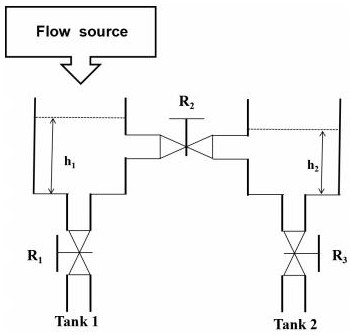

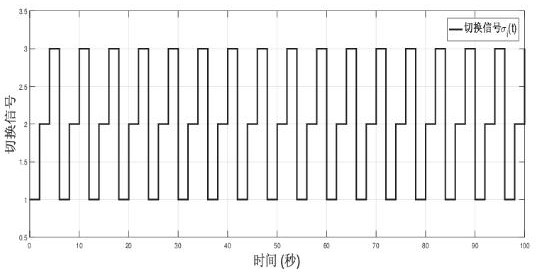

[0051] The present invention takes the chemical process liquid level control system model as the implementation object, and proposes a robust fault diagnosis method for the uncertain switching linear system of the chemical process liquid level control system, based on a proportional integral observer. Fault diagnosis, this method theoretically realizes the elimination of external disturbances in the fault diagnosis system, and can also meet the fault detection and estimation of the system.

[0052] Note: In this invention, the P T ,P -1 respectively represent the transposition of the matrix P and the inverse matrix of the matrix, P>0 (Pn Represents an n-dimensional real vector set, and I and 0 represent the identity matrix and 0 matrix with appropriate dimensions. For a vector A, sym(A)=A T +A, * in the text represents the symmetric item in the symmetric matrix. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com