Performance Evaluation Method and System of Control Rod Drive Mechanism Based on Action Critical Sequence

A driving mechanism and control rod technology, applied in the direction of nuclear power generation, climate sustainability, greenhouse gas reduction, etc., can solve the problems of inaccurate online monitoring results, harsh working environment, large errors, etc., to achieve predictive maintenance, solve The effect of online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

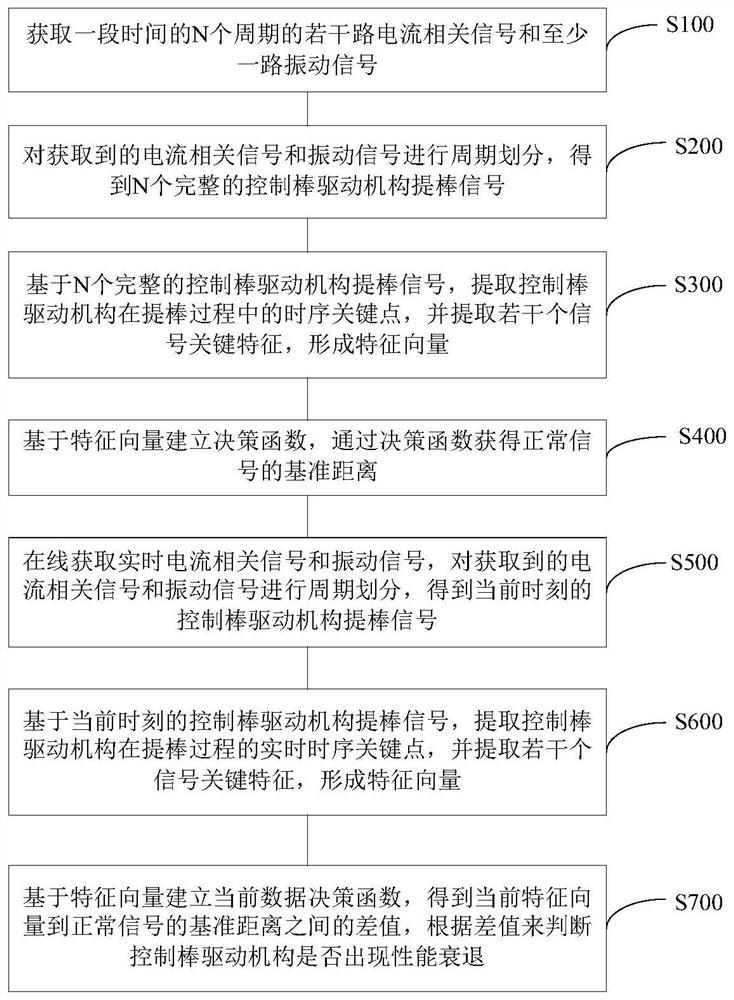

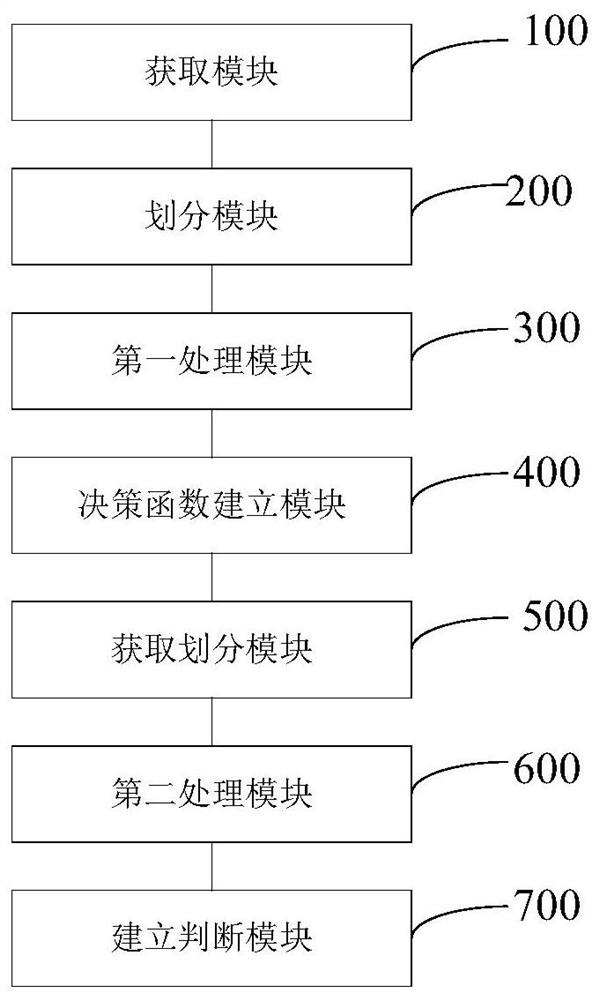

[0096] A performance evaluation system of the control rod drive mechanism based on the critical sequence of actions, such as figure 2 As shown, it includes an acquisition module 100, a division module 200, a first processing module 300, a decision function establishment module 400, an acquisition division module 500, a second processing module 600, and a judgment module 700:

[0097] The acquiring module 100 is configured to acquire several current-related signals and at least one vibration signal of N periods for a period of time;

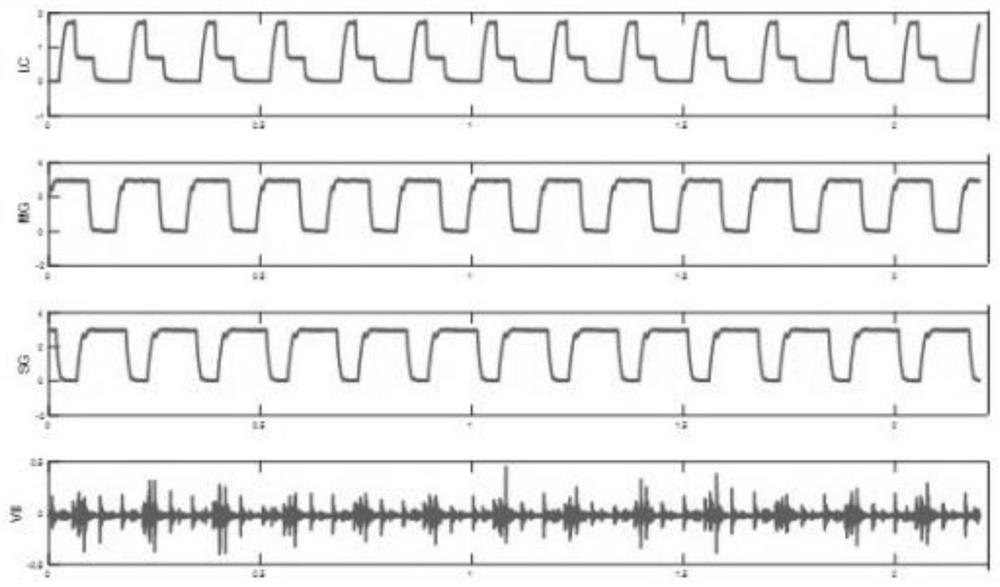

[0098] The division module 200 is configured to periodically divide the acquired current-related signals and vibration signals to obtain N complete control rod driving mechanism rod lifting signals;

[0099] The first processing module 300 is configured to extract timing key points of the control rod driving mechanism during the rod lifting process based on N complete control rod driving mechanism lifting signals, and extract several key features...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com