Method for activating fuel cell stack

A fuel cell stack, fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of long activation process time, inability to meet mass production, etc., and achieve shortened activation time and good electrochemical performance. Performance, simple effect of activation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

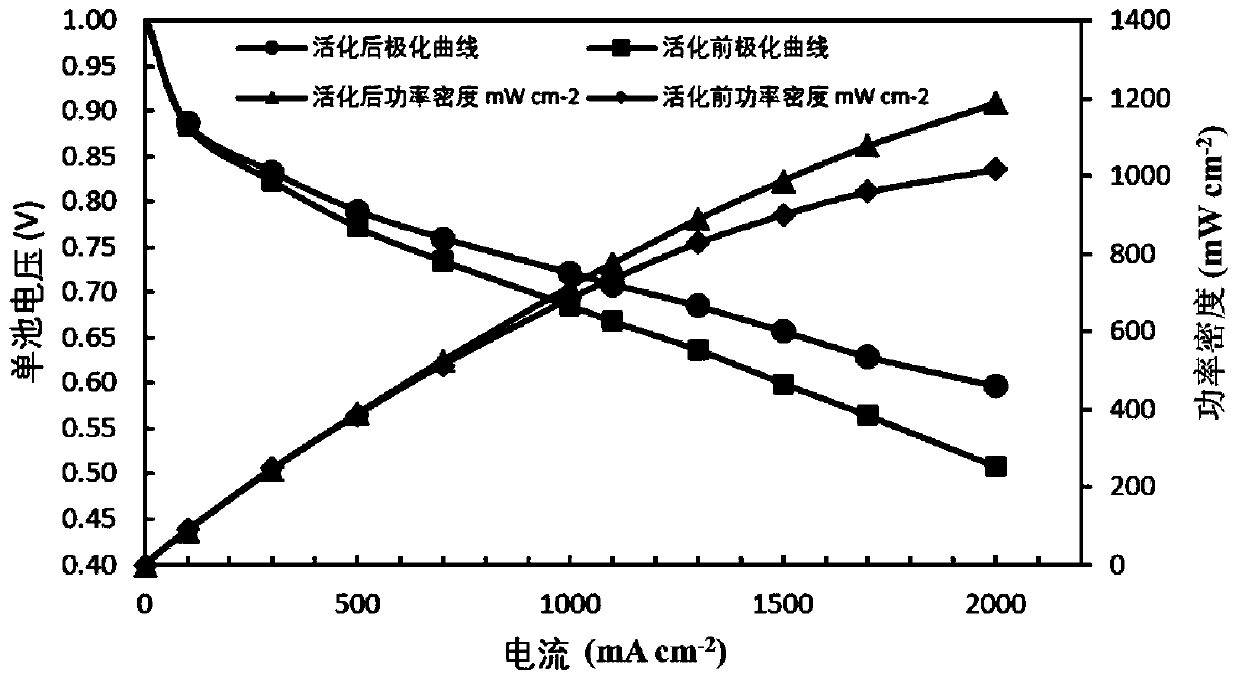

Embodiment 1

[0076] A method for activating a fuel cell stack comprises the steps of:

[0077] (1) Pre-activation operation:

[0078] (a) to the fuel electrode supply of the fuel cell, the relative humidity is 80% hydrogen, the air electrode supply is 80% air, and the open circuit voltage V of the single cell is adjusted 4 1V for 5 minutes;

[0079] (b) Stop the gas supply to the fuel electrode and the air electrode, feed humidified nitrogen gas with a relative humidity of 80% to the two poles of the fuel cell, and purge the stack with nitrogen gas until the single-cell voltage V 2 down to 0.45V;

[0080] (c) Stop the nitrogen supply to the electrodes on both sides of the fuel cell, feed air with a humidity of 80% to the fuel electrode side, and feed hydrogen with a relative humidity of 80% to the air electrode side for 10 minutes;

[0081] (d) Stop the gas supply to the fuel electrode and the air electrode, and pass humidified nitrogen gas with a relative humidity of 80% to the two pol...

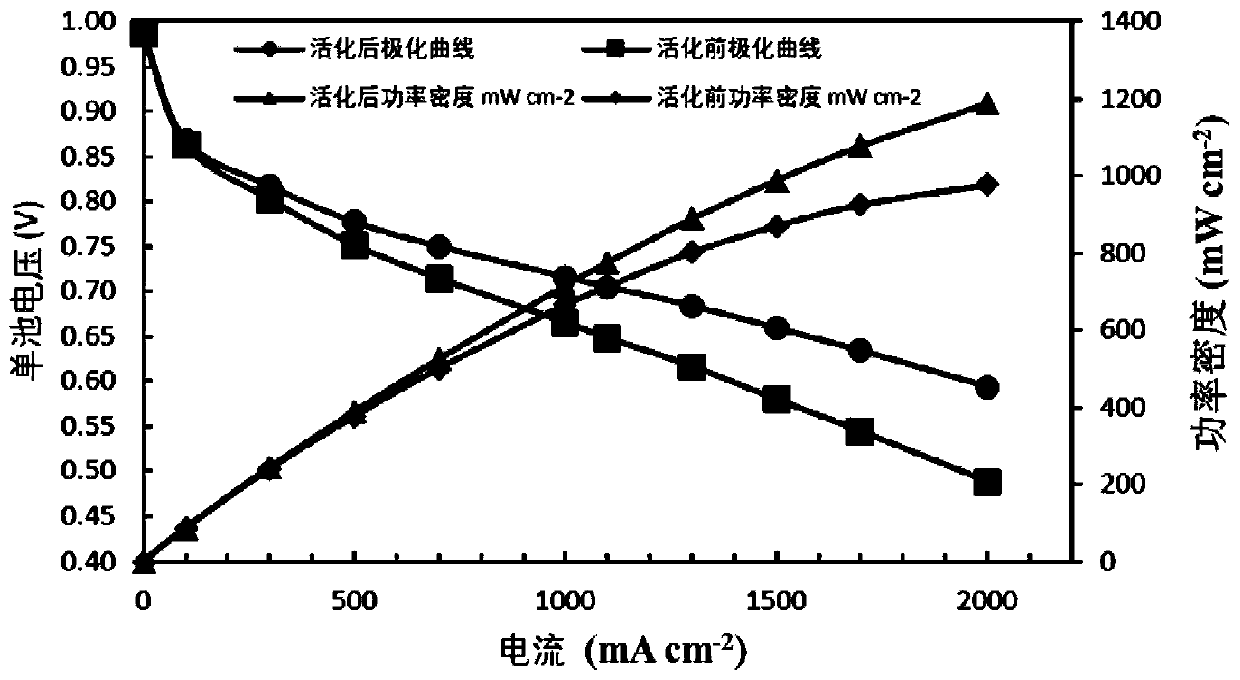

Embodiment 2

[0089] A method for activating a fuel cell stack comprises the steps of:

[0090] (1) Pre-activation operation:

[0091] (a) to the fuel electrode supply of the fuel cell, the relative humidity is 85% hydrogen, the air electrode supply is 85% air, and the open circuit voltage V of the single cell is adjusted 4 1.1V for 6 minutes;

[0092] (b) Stop the gas supply to the fuel electrode and the air electrode, feed humidified nitrogen gas with a relative humidity of 85% to the two poles of the fuel cell, and purge the stack with nitrogen gas until the single-cell voltage V 2 down to 0.47V;

[0093] (c) Stop the nitrogen supply to the electrodes on both sides of the fuel cell, feed air with a humidity of 85% to the fuel electrode side, and feed hydrogen with a relative humidity of 85% to the air electrode side for 10 minutes;

[0094] (d) Stop the gas supply to the fuel electrode and the air electrode, and pass humidified nitrogen gas with a relative humidity of 85% to the two p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrochemically active area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com