Combined high-current stamping terminal and reed structure

A high-current, combined technology, applied in the direction of circuits, electrical components, coupling devices, etc., can solve the problems of complicated installation, unreasonable conduction structure design, and narrow installation space of wiring in the car, so as to achieve high contact stability of connection current, The connection method is flexible and changeable, and it is easy to adjust the effect of tolerance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

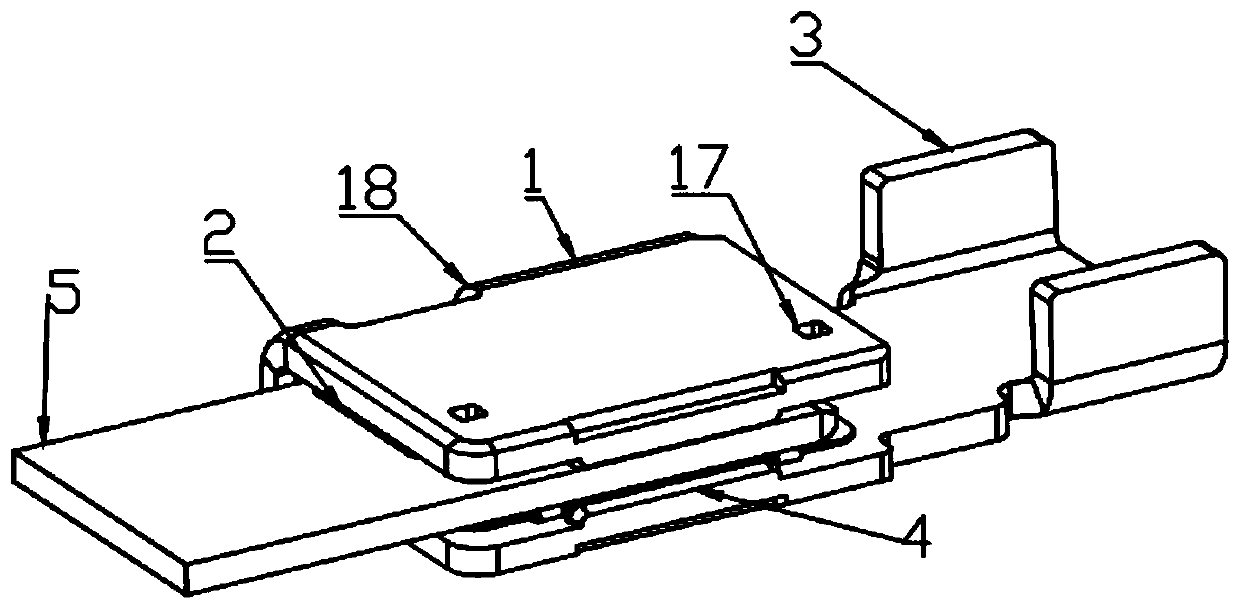

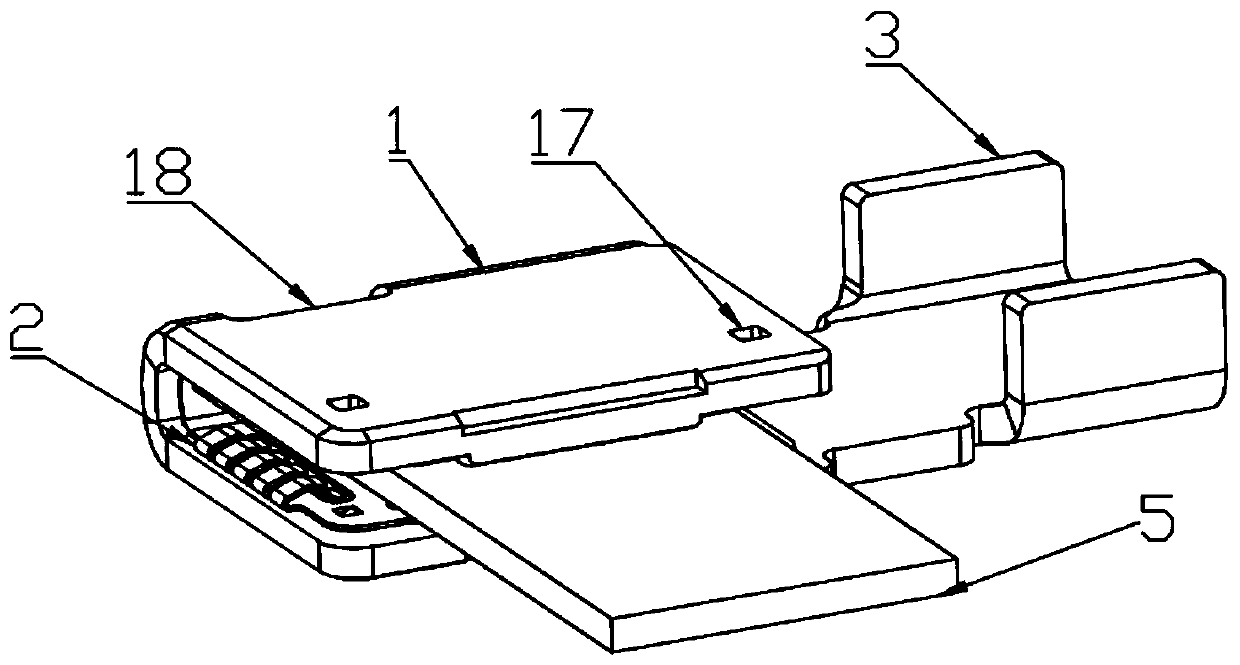

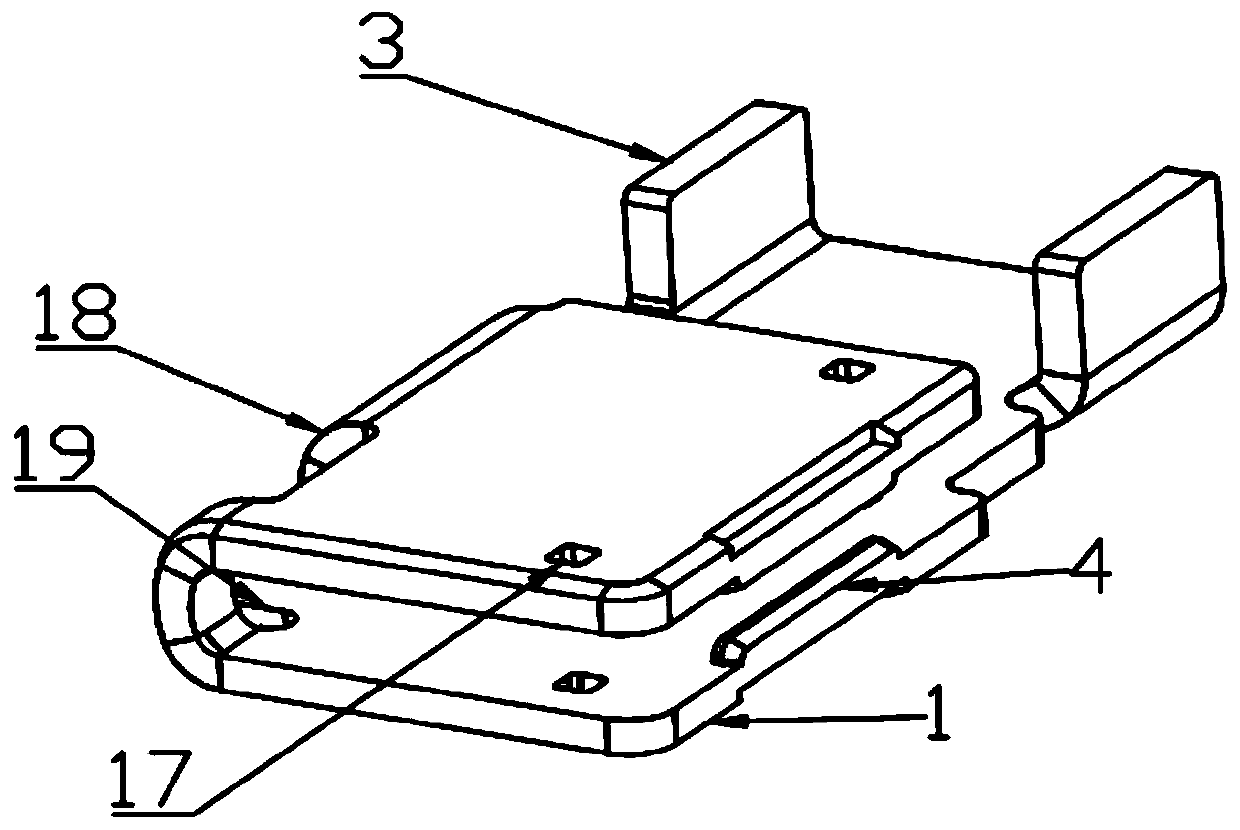

[0023] Such as Figure 1 to Figure 7 As shown, a combined high-current stamping terminal and reed structure includes a "U"-shaped opening-shaped sheath body 1 and a reed body 2. The side end of the sheath body 1 is connected with a copper wire for fixing the cable. The sheath wire lug 3 of the core, the upper and lower ends of the opening of the sheath body 1 are provided with a pair of plug-in limit ribs 4 with guide angles, and the reed body 2 is embedded in the sheath body 1 and is used for inserting copper bars sheet 5, the reed main body 2 includes a plurality of guiding contact fingers 1 6, guiding contact fingers 2 7 and contact contact fingers 8, and the reed main body 2 has a strip-shaped opening 9 and a strip-shaped opening 9 and a strip opening respectively at adjacent two sides. Shaped opening two 10, several guide contact fingers one 6 and guide contact fingers two 7 are bow tongue-shaped and the roots are connected with the reed main body 2 at a certain bow angle...

Embodiment 2

[0032] Such as Figure 8 As shown, the difference from Embodiment 1 is that the reed main body 2 is still embedded in the sheath main body 1, and the original clamping connection mode is changed to a plurality of fixing columns 20 fixed on the sheath main body 1. The connection mode of riveting with the reed main body 2.

[0033] Based on the above, the present invention has the following beneficial effects: 1. Ensure high electrical conductivity while satisfying simplicity, convenient installation and operation, and high contact stability of the connection current; 2. The product structure is changed from the traditional machining process to the sheet metal stamping process. , easy to adjust tolerance consistency. Avoid inconsistencies in product performance due to accumulated tolerances; 3. The product structure is converted from traditional cylinders to sheet metal stamping, which is improved to increase contact points at equal volumes while satisfying 90° and 180° two-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com