Sheet feeding machine

A feeder and sheet material technology, applied in the direction of thin material processing, lamination auxiliary operation, object separation, etc., can solve the problems of low positioning accuracy, affecting product output accuracy, easy to absorb multiple pieces of material, etc., to achieve the degree of automation High, guaranteed production precision, the effect of guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

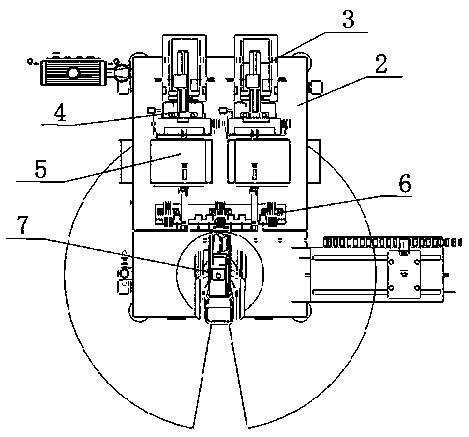

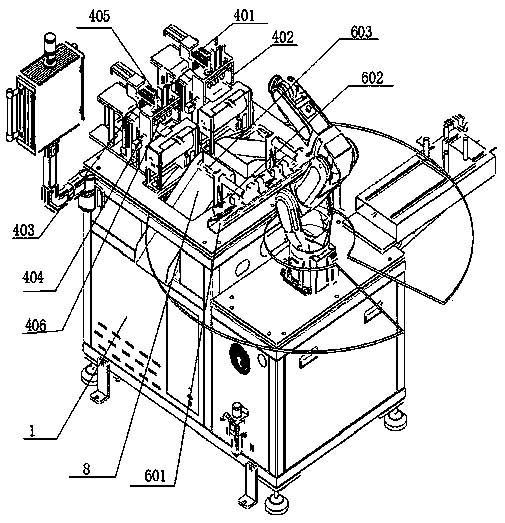

[0032] Such as Figure 1~5 As shown, a sheet feeder includes a base 1, a feeding unit and a six-axis robot 7, at least two groups of feeding units are provided on the base 1, and a mounting plate 2 is provided on the base 1, and the feeding unit is installed on On the mounting plate 2, each group of feeding units includes a carrying mechanism 3, a transport mechanism 4, a stripping mechanism 5 and a waste processing mechanism 6, and a six-axis robot 7 cooperates with the stripping mechanism 5;

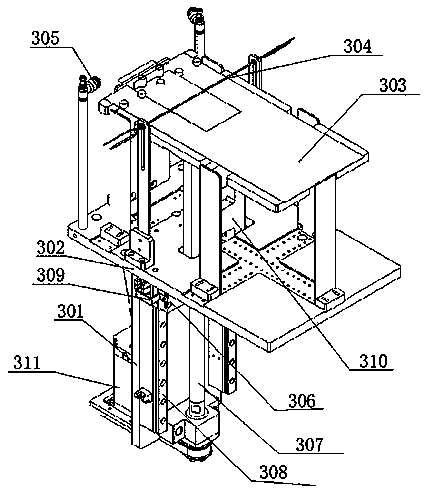

[0033] The carrying mechanism 3 includes a lifting module, a supporting plate 302, and a sheet material lifting plate 303. The lifting module is located on the lower end surface of the mounting plate 2, the supporting plate 302 is fixedly installed on the upper end of the mounting plate 2, and a sheet is arranged above the supporting plate 302. The material lifting plate 303, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com