Automatic laying device for waterproof membrane for outdoor building

An automatic laying and waterproof membrane technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of low levelness of manual laying, flat waterproof membrane, not worth promoting, etc., to achieve ingenious structural design and reduce manpower The effect of simple use and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

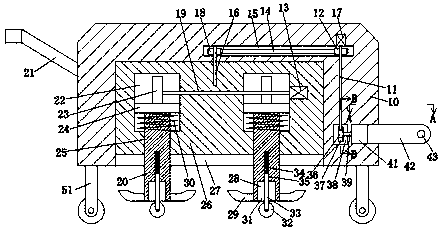

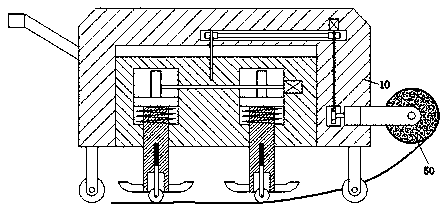

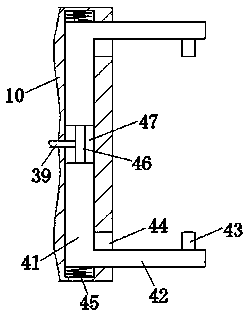

[0019] Combine below Figure 1-5 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0020] refer to Figure 1-5 According to an embodiment of the present invention, an automatic waterproof membrane laying device for outdoor construction includes a laying machine body 10, and a lifting chute 27 is symmetrically arranged on the bottom end surface of the laying machine body 10, and the lifting chute 27 is slidably installed There is a lifting carriage 26, and a telescopic slide chamber 25 is symmetrically arranged in the left and right sides of the end face of the bottom of the lift carriage 26, and a telescopic slide block 20 is slidably installed in the telescopic slide chamber 25, and the bottom of the end faces of the left and right sides of the telescopic slide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com