Unloading device matched with rotary excavating machine and method

A technology of unloading device and rotary excavator, which is applied to rotary drilling rigs, drilling equipment and methods, packaging, etc., can solve the problems of not being directly stacked on the ground, difficult to operate equipment efficiently, etc., and achieve simple structure, easy maintenance and Transportation, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

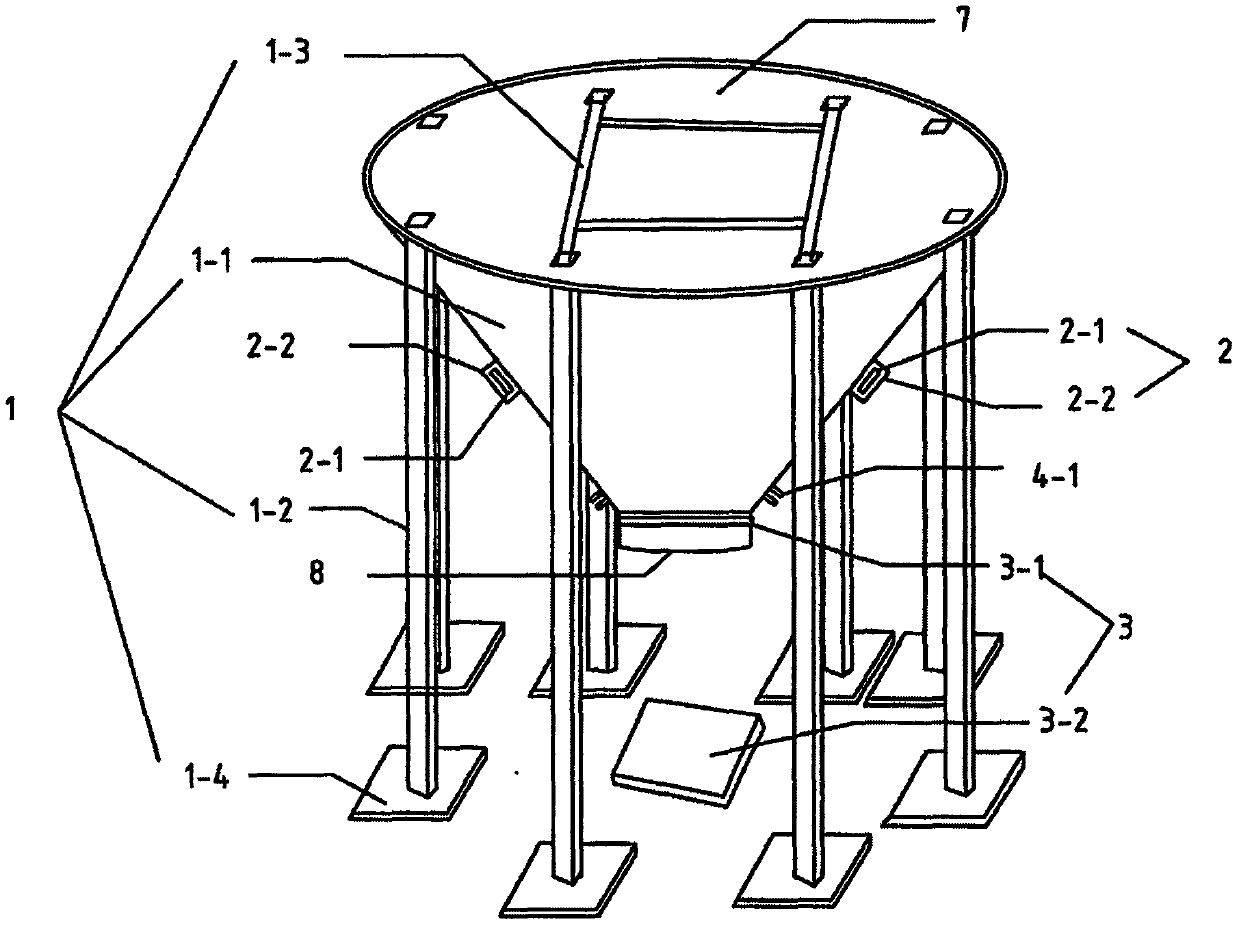

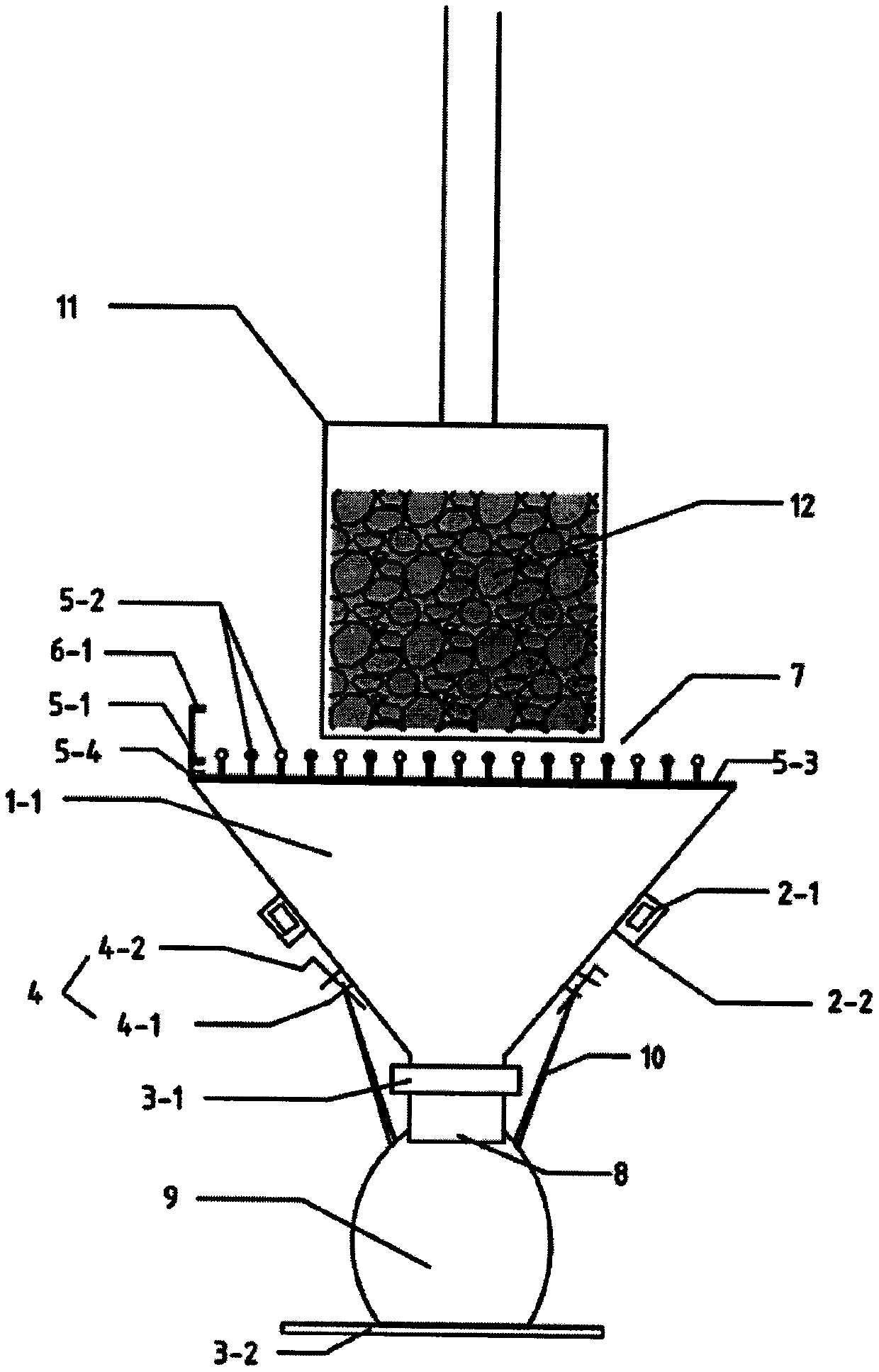

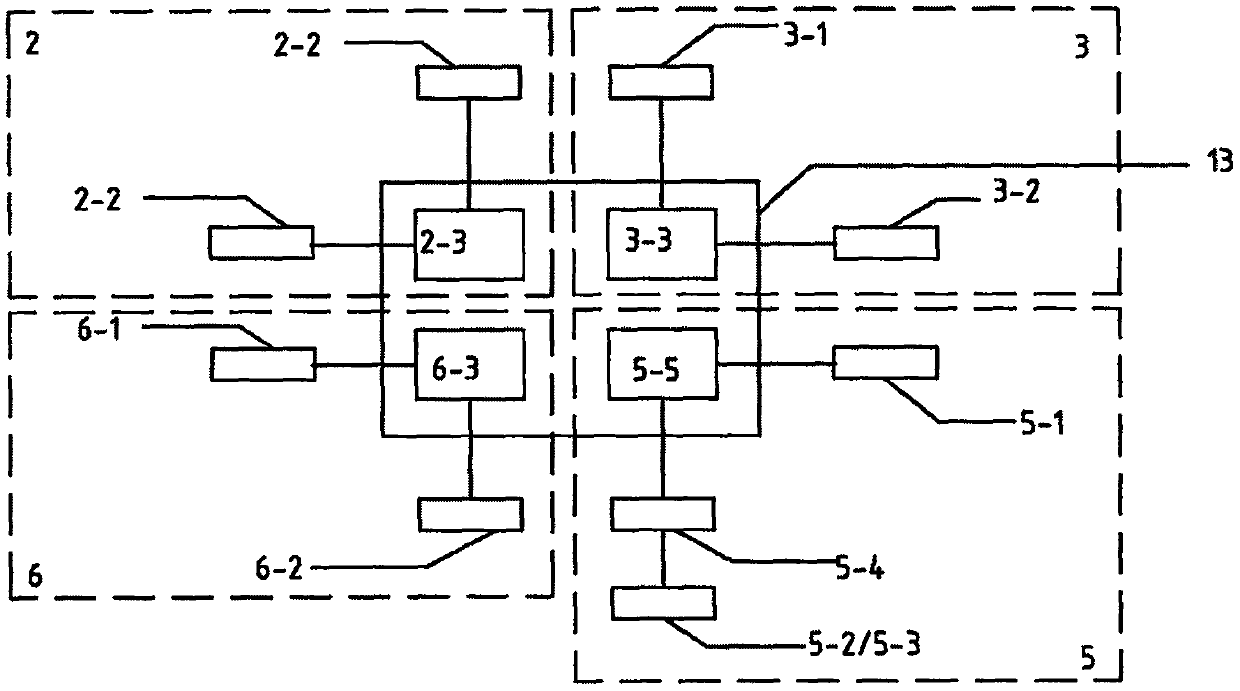

[0043] A discharge device for a rotary excavator, comprising a hopper mechanism 1, a hopper mechanism 1, a vibrating mechanism 2, a weighing mechanism 3 for unloading, a ton bag fixing mechanism 4, a spray mechanism 5 and an early warning mechanism 6, wherein the hopper The mechanism 1 includes a funnel-shaped main body 1-1, a first bracket 1-2 and a second bracket 1-3, the bottom side of the funnel-shaped main body 1-1 contacts or connects with the first bracket 1-2, and the funnel-shaped main body 1-1 Suspended on the ground under the support of the first support 1-2, the bottom side of the first support 1-2 is installed with feet; Two brackets 1-3, the vibration mechanism 2 is installed on the outside of the funnel-shaped main body 1-1 to assist the waste 12 in the funnel to break away from the funnel-shaped main body 1-1; the spray mechanism 5 is installed on the feed of the funnel-shaped main body 1-1 Port 7; vibration mechanism 2 and warning mechanism 6 are electrically ...

Embodiment 2

[0057] Embodiment 2 discloses a method for unloading a shoe material device that is compatible with a rotary excavator based on the embodiment, including the following steps:

[0058] First install the large bag 9 on the funnel-shaped main body 1-1, so that the edge of the large bag 9 is connected to the hook;

[0059] Set the weighing weight value a of the weighing device; set the detection height corresponding to the second sensor 6-1;

[0060] The rotary excavator turns the drill bit 11 loaded with waste 12 to the top of the feed port 7 and starts to descend. After the second sensor 6-1 detects the drill bit 11, the alarm 6-2 emits a warning sound, and then the drill bit 11 moves down. The speed slows down. When the first sensor 5-1 detects the drill bit 11, the second control valve 5-4 controls the spray pipe 5-3, and water is sprayed from the spray head 5-2;

[0061] The drill bit 11 slowly moves down to the second bracket 1-3, and the cover of the drill bit 11 is opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com