Drill loader working device

A technology of working devices and drilling rigs, which is applied in the direction of supporting devices, drilling equipment, earthwork drilling and mining, etc., can solve the problems of low overall efficiency, reduced work efficiency, and many auxiliary processes, and achieves a large stroke range, high work efficiency, The effect of accurate hole positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

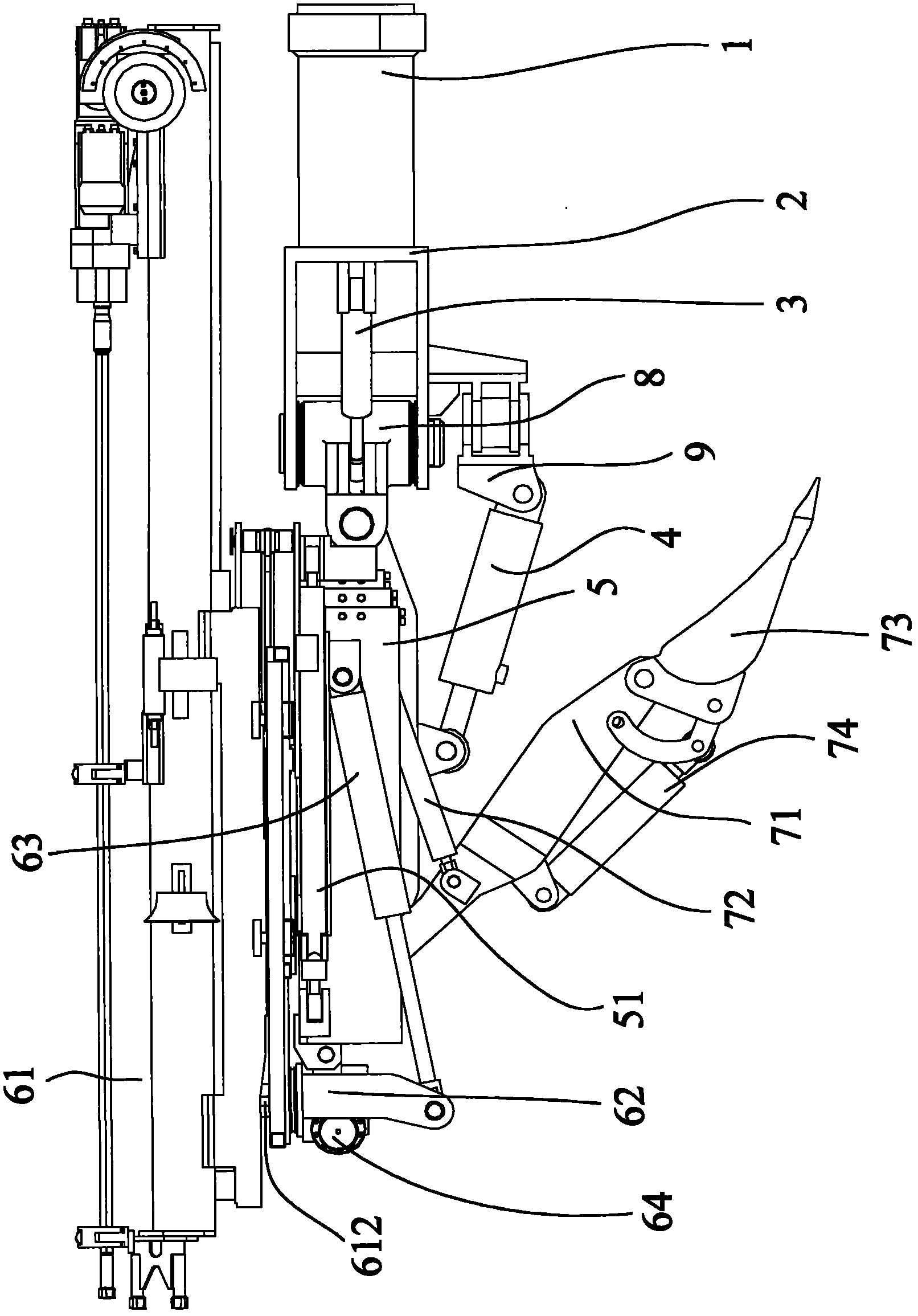

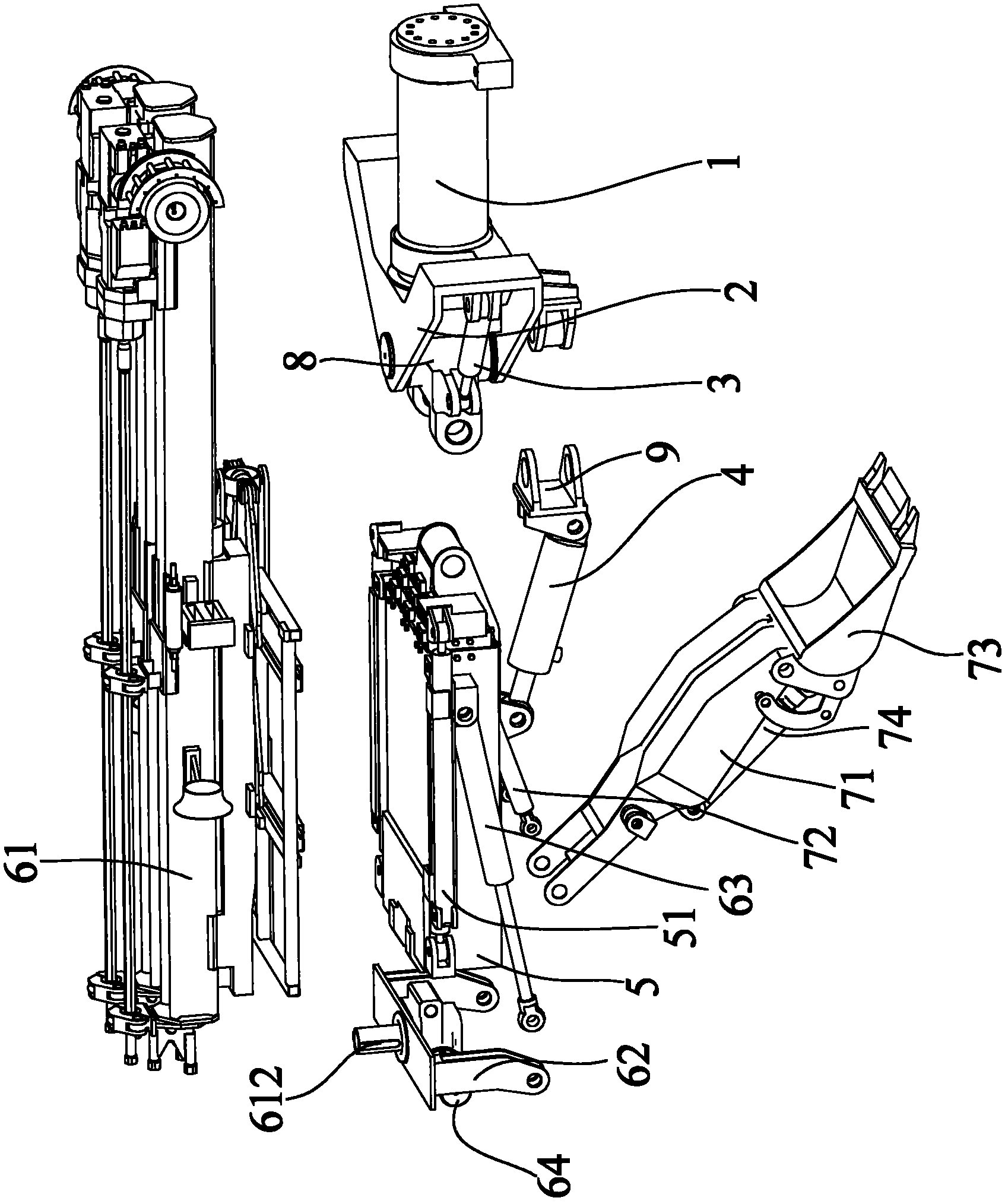

[0052] figure 1 It shows a schematic structural view of an embodiment of the working device of the drilling machine according to the present invention, figure 2 show figure 1 A perspective view of disassembly of the embodiment shown.

[0053] Such as figure 1 with figure 2 As shown, the working device of the drilling machine provided by the present invention includes a drilling assembly, an excavating assembly and a main arm assembly, and the main arm assembly is rotatably installed on the body of the working device of the drilling machine (not shown in the figure Out), the main arm assembly includes a main arm body 5, the drilling assembly and the excavation assembly can be movably installed on the main arm body 5, the drilling assembly and the The excavating assembly can be driven by the main arm body 5 to perform the same movement as the main arm body 5 .

[0054] Adopting such a technical solution, the drilling assembly and the excavating assembly are integrated int...

Embodiment 2

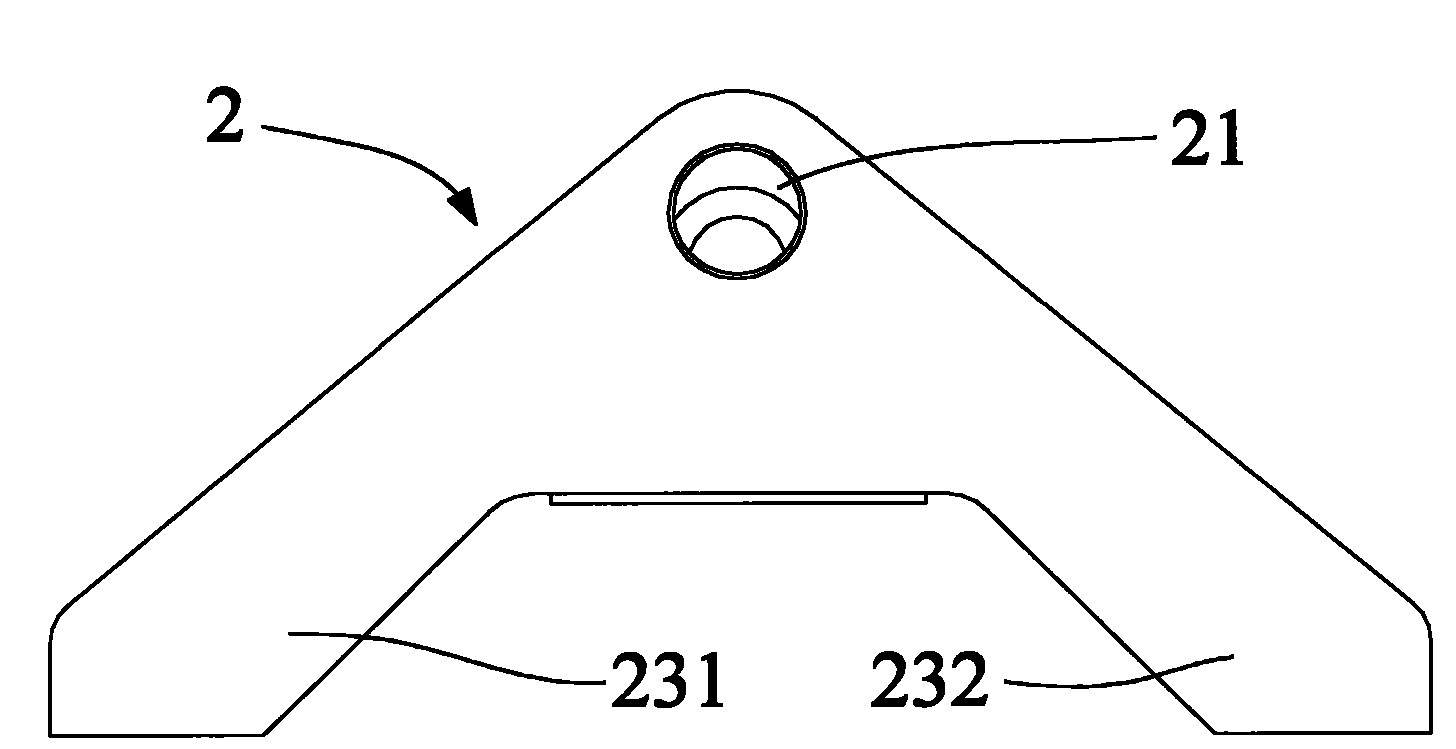

[0083] Figure 14 It shows a schematic structural view of another embodiment of the working device of the drilling machine according to the present invention, Figure 15A show Figure 14 The schematic diagram of the front view of the connecting seat of the main arm in the shown embodiment, Figure 15B show Figure 15A The schematic side view of the connecting seat of the main arm shown, Figure 15C show Figure 15A The schematic top view of the connecting seat of the main arm shown.

[0084] Such as Figure 14 As shown, Embodiment 2 mainly changes the structure of the main arm connecting seat 2 in Embodiment 1 and the connection relationship between the rotary cylinder 1 and the main arm connecting seat 2, and correspondingly changes the lifting cylinder 4 and the main arm. The connection relationship of connection socket 2 has been changed. Such as Figure 15A with 15B And as shown in 15C, the main arm connecting seat 2 is a hollow structure, the rotor of the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com