Full-automatic anchor rod drill rig used for coal mine

A bolter drilling rig, fully automatic technology, applied in the direction of installing bolts, drill pipes, drill pipes, etc., can solve the problems of low efficiency and insufficient automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Refer below Figure 1 to Figure 30 The technical solution of the present invention will be further elaborated in conjunction with the embodiments.

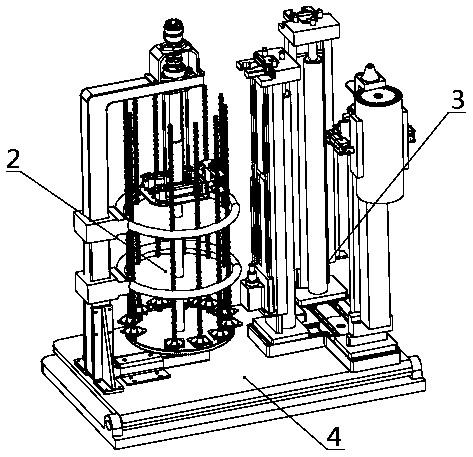

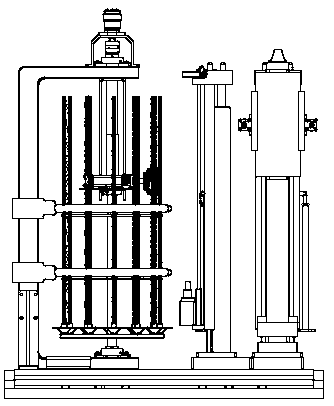

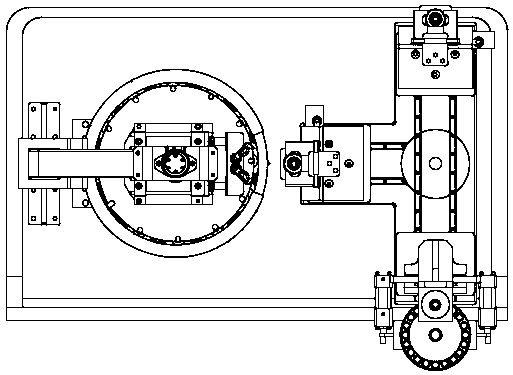

[0055]This embodiment provides a fully automatic rock bolter for coal mines, which includes an automatic bolting device 3 , an automatic rod feeding device 2 and a supporting base device 4 . The automatic bolting device 3 and the automatic rod feeding device 2 are fixed on the support base device 4, and in the automatic bolting device 3, the anchor base 321 is partially fixed on the inner side of the support base device 4 along the length direction, and the drill pipe base 307 The part and the anchoring agent base 320 are fixed on the edge position of the support base device 4 along the length direction; the automatic rod feeding device 2 and the anchor rod base 321 are partly separated by a certain distance, and the automatic rod feeding device 2 is fixed on the elongation direction of the support base device 4 Another ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com