Air-conditioning type three-way flow adjusting valve

A rectifier valve and controlled atmosphere technology, applied in the field of controlled atmosphere three-way rectifier valve, can solve the problems of poor sealing performance, easy wear of the valve core, complex structure, etc., to achieve good sealing performance, reduce workload, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

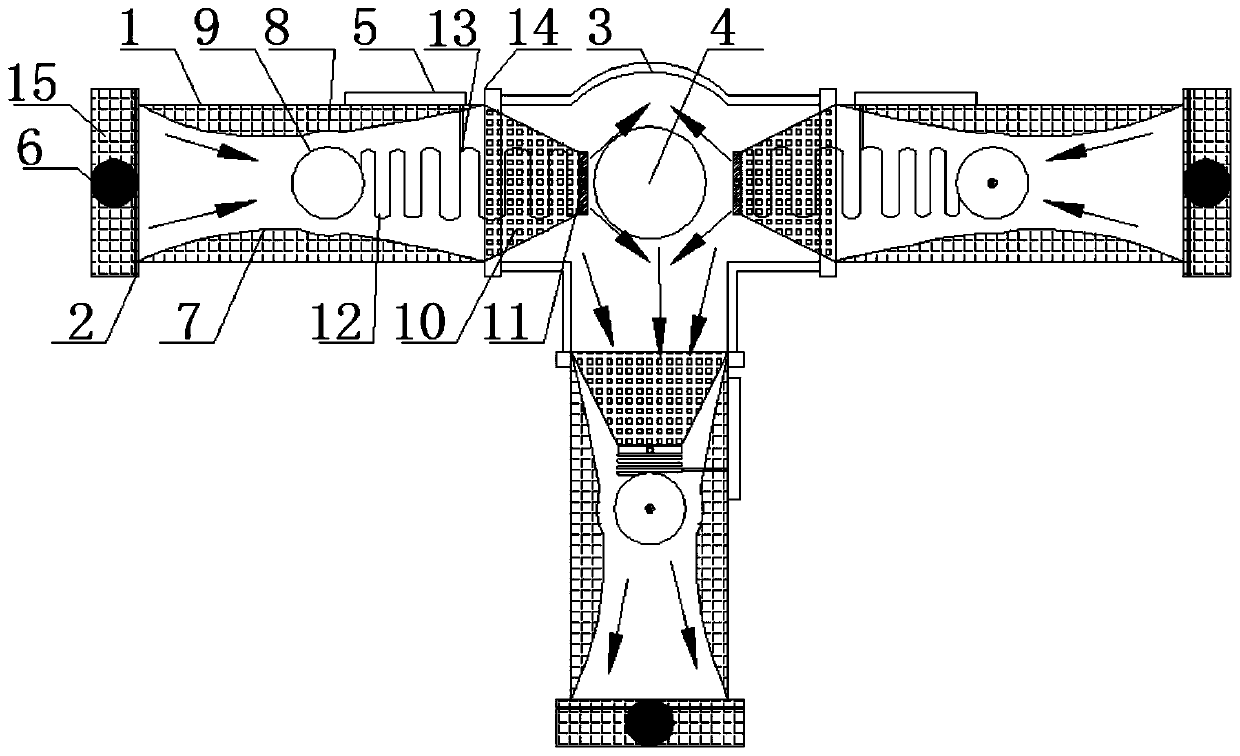

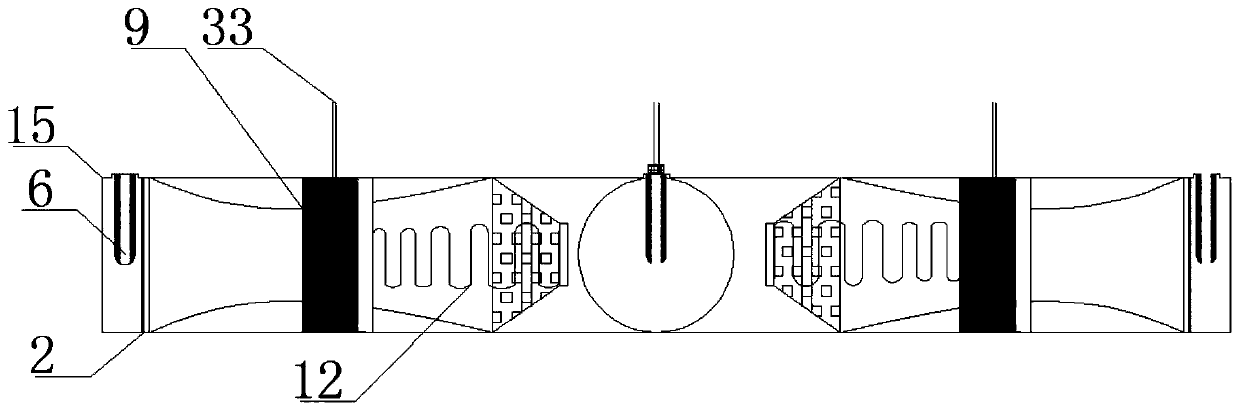

[0036] combine figure 1 and figure 2 , the air-adjustable three-way rectifier valve in this embodiment includes a fluid impact chamber 3 and three diversion pipes 1 that are respectively connected to the fluid impact chamber and have the same structure. The three diversion pipes form a "T" with the fluid impact chamber shaped structure.

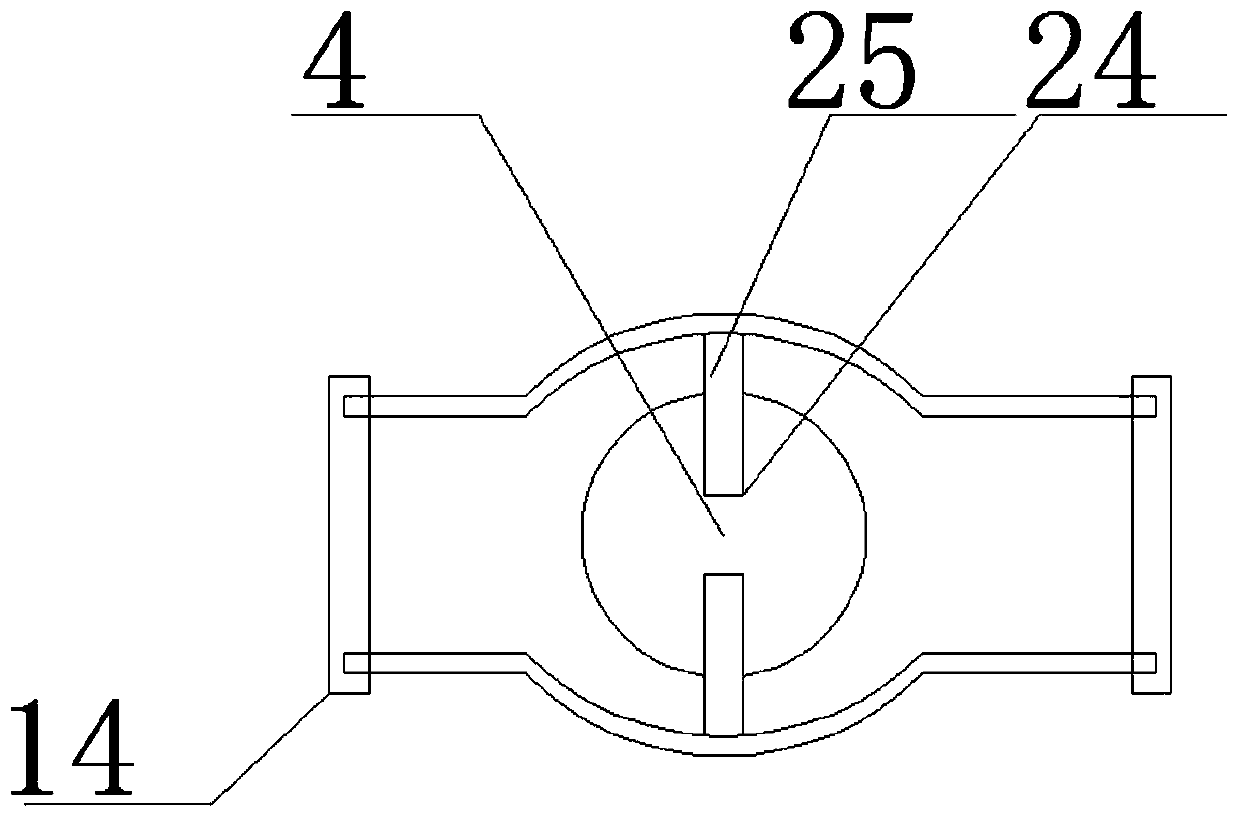

[0037] combine figure 1 , figure 2 and image 3, the fluid impact chamber is spherical, and there is a solid fluid impact ball 4 in the fluid impact chamber. The fluid impact ball passes through the connecting hole 24 provided on its outer wall and the connecting column 25 installed on the inner wall of the impact chamber. center of the room.

[0038] to combine figure 1 , figure 2 and Figure 4 to Figure 8 , the three diversion pipes 1 are respectively formed by docking the upper casing 27 of the diversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com