Double-wall corrugated pipeline bell and spigot strengthening method and profiling wrapping structure

A double-wall corrugated pipe, corrugated pipe technology, applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve problems such as deformation space, and achieve the effect of improving structural strength, simple preparation and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0024] Embodiments of the invention

[0025] A double-wall corrugated pipe socket reinforcement method is to sequentially cover a flexible inner layer and a reinforced shell outside the socket of a solid-walled double-wall corrugated pipe, and provide a deformation space during socketing through the flexible function of the flexible inner layer. The shell increases structural strength.

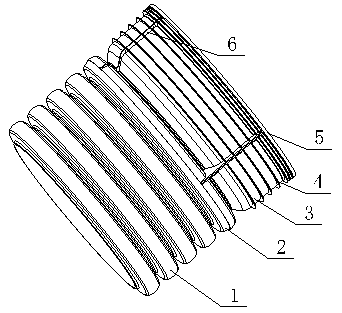

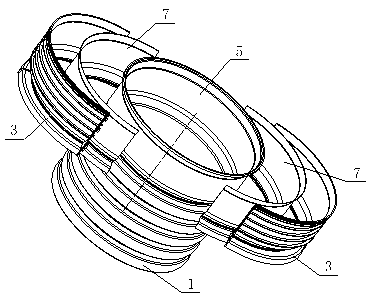

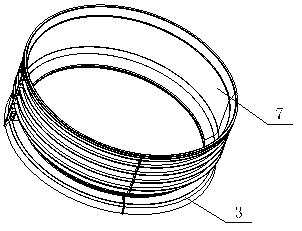

[0026] A double-wall corrugated pipe socket profiling cladding structure for realizing the above method, as attached Figure 1-6 As shown, it includes a contoured flexible inner layer 7 coated on the outer wall of the double-wall bellows socket 5 , and the contoured flexible inner layer 7 is covered with a contoured reinforced shell 3 .

[0027] The profiling flexible inner layer 7 and the profiling reinforced shell 3 are independently proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com