Purification smoke hood all-in-one machine

An all-in-one machine and fume hood machine technology, applied in the field of fume exhaust hoods, can solve the problems of inability to increase the area of oil fume suction, low smoke exhaust efficiency, single function, etc., and achieve the effects of facilitating promotion, improving emission efficiency, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

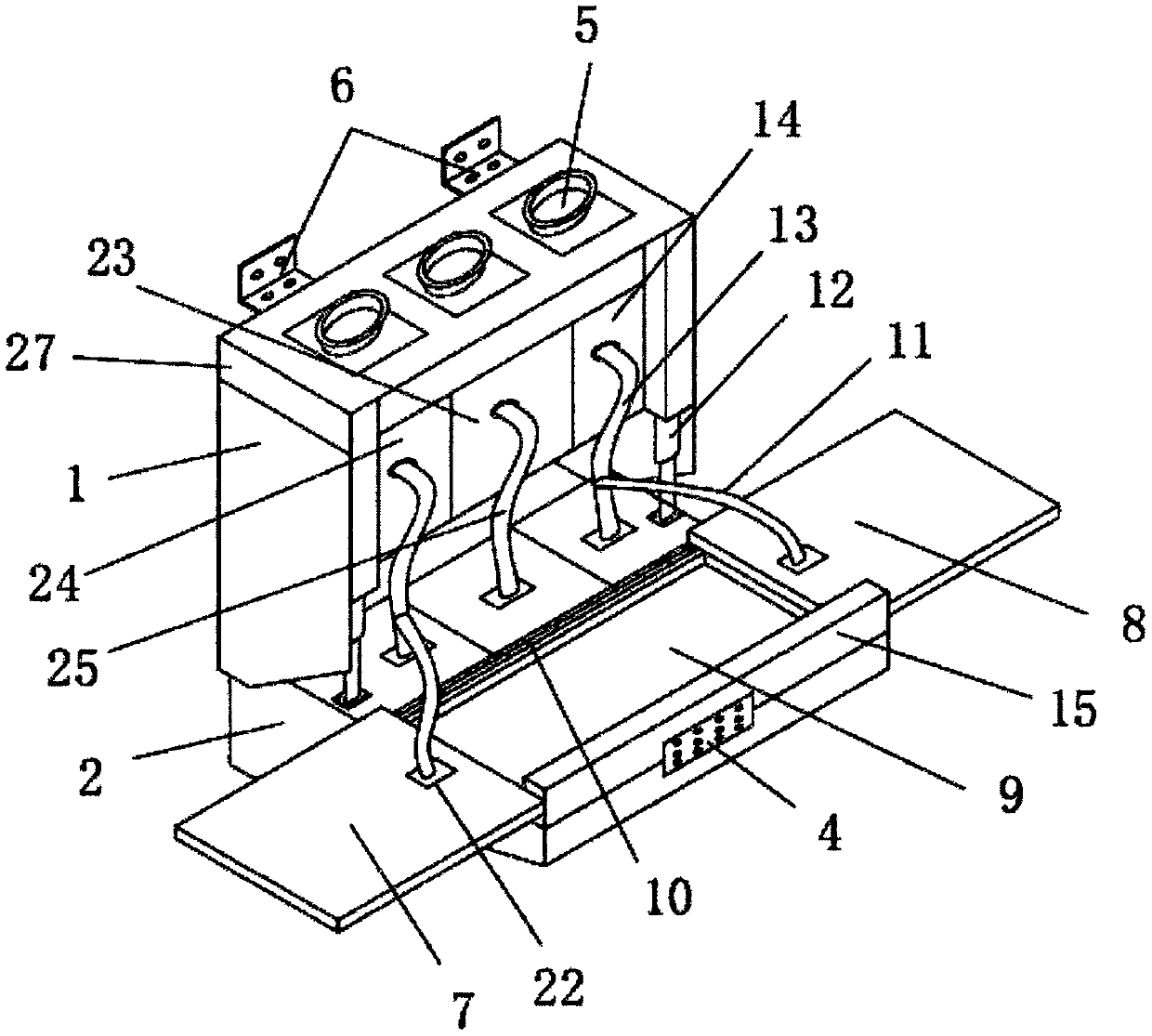

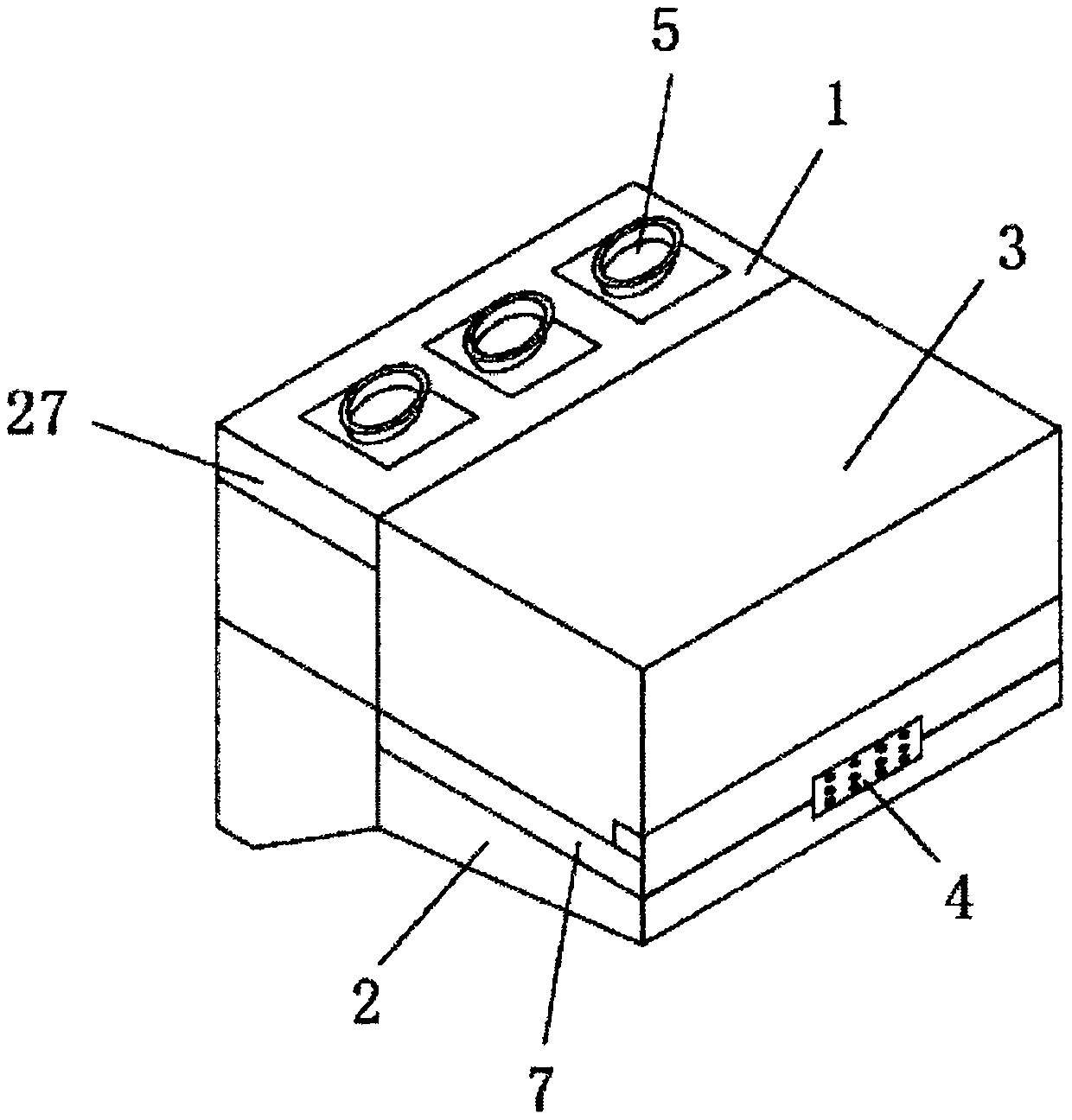

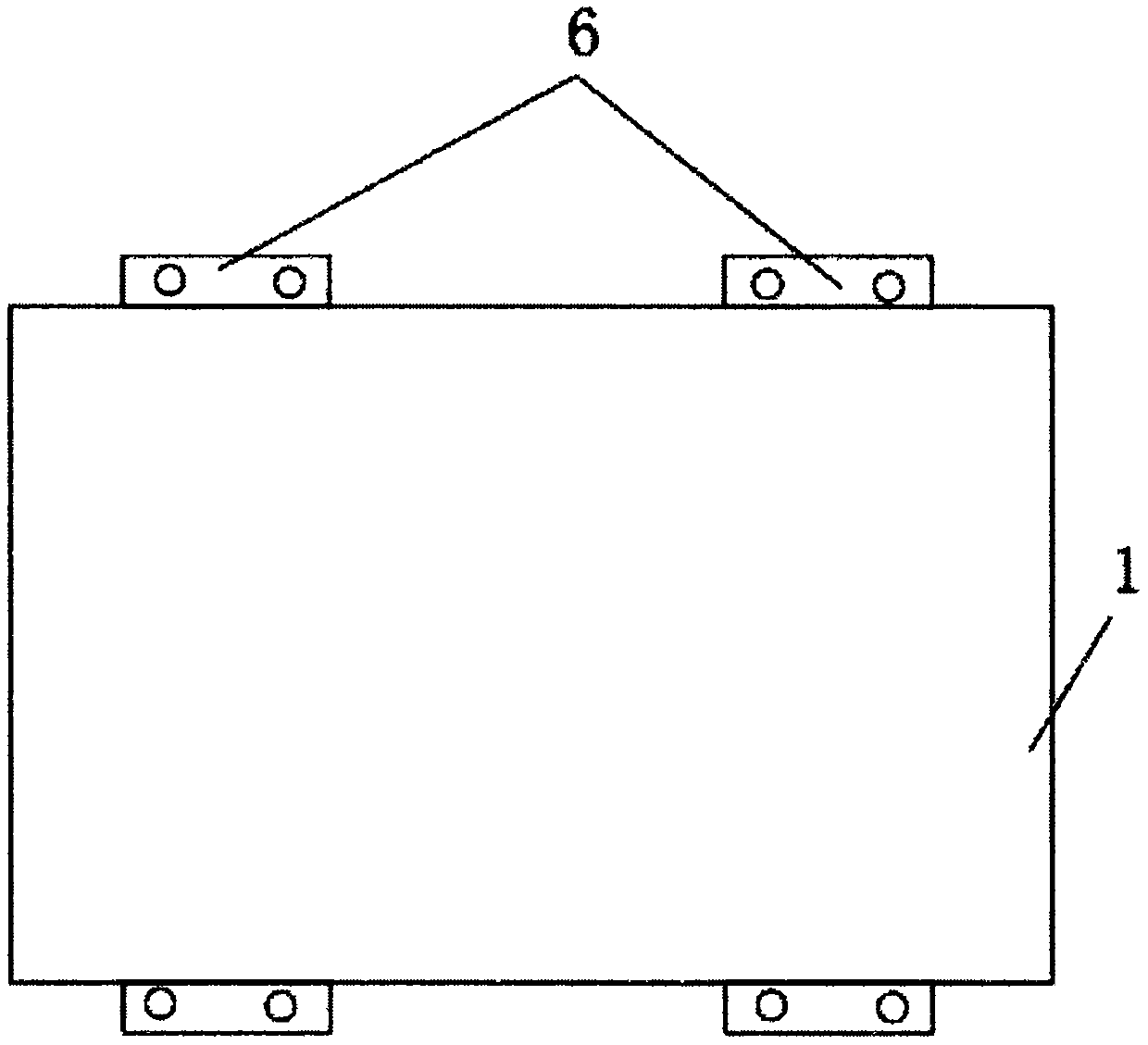

[0023] see Figure 1-6 , the present invention provides a technical solution: an all-in-one purifying fume hood, including a fume hood body 1, one side of the fume hood body 1 is provided with an L-shaped fixing part 6, and the interior of the fume hood body 1 is respectively provided with The first fan box 14, the second fan box 23 and the third fan box 24, the first electric telescopic rod 12 is fixed on both sides inside the fume hood body 1, and the bottom end of the first electric telescopic rod 12 is fixed with a smoking box 2. One side of the smoking box 2 is provided with a waste oil tank 9, one side of the waste oil tank 9 is provided with a chute 10, both sides of the waste oil tank 9 are provided with waste oil box fixing grooves 17, and the inside of the waste oil tank 9 is provided with Waste oil box 16, both sides of waste oil box 16 are welded with waste oil box fixing blocks 18, the other side of waste oil tank 9 is provided with smoking plate movable box 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com