High-low fin reinforced condensation heat exchange tube

A heat exchange tube and tube body technology, which is applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of improving heat exchange performance, insufficient heat exchange efficiency, and inability to fully utilize the surface tension of condensate, etc. Achieve the effect of reducing thermal resistance, improving heat transfer effect, and reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

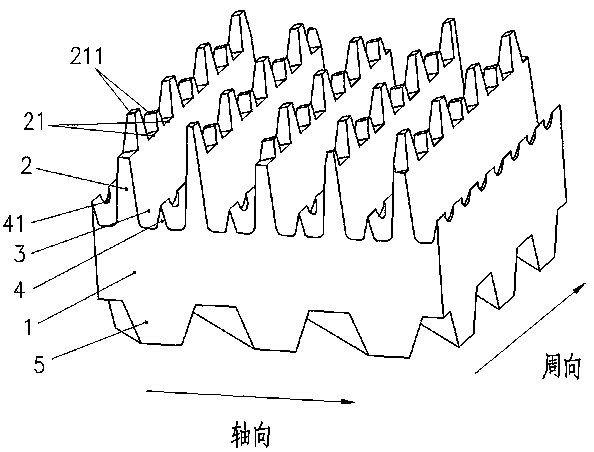

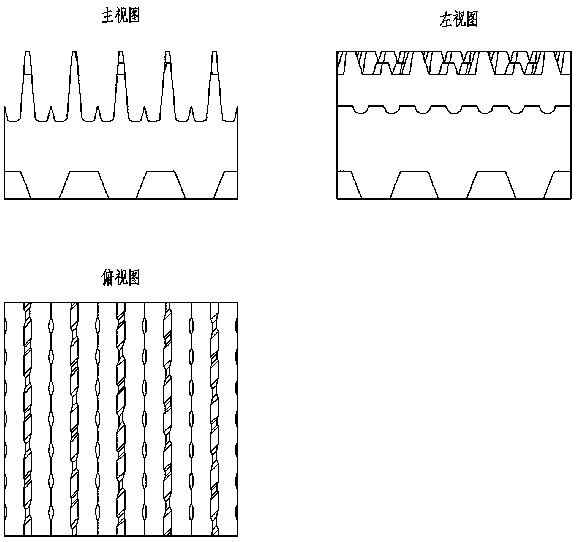

[0026] refer to figure 1 , figure 2 As shown, it shows a schematic structural view and three views of the first embodiment of a high and low fin enhanced condensation heat exchange tube of the present invention. In this preferred embodiment, the heat exchange tube includes a tube body 1 with an inner cavity, and the tube The outer surface of the body 1 is provided with primary outer fins 2 that are distributed in a spiral shape and are integrated with the tube body 1, and the space formed between the adjacent primary spiral outer fins 2 forms interconnected channels. 3 structure, the top of the first-stage spiral outer fin 2 is provided with first grooves 21 that are both interlaced and communicated with the channel 3, and the first grooves 21 are spaced apart along the thread extension direction of the first-stage spiral outer fin 2 Arranged so that the top of the primary helical outer fin 2 forms an uneven wing tip 211 structure.

[0027] The bottom of the channel 3 is pr...

Embodiment 2

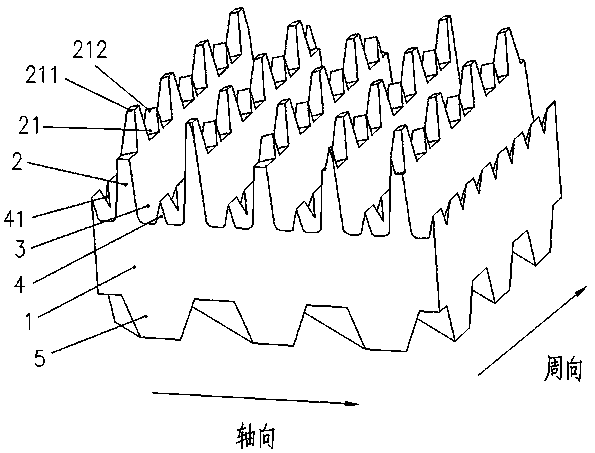

[0029] refer to image 3 , Figure 4 As shown, it shows a schematic structural view and three views of the second embodiment of a high-low fin enhanced condensation heat exchange tube of the present invention. In this preferred embodiment, its basic structure and principle are the same as those of the first embodiment, the difference is The cross-sectional profile of the second groove 41 of the heat exchange tube is V-shaped.

[0030] The present invention is a high and low fin enhanced condensation heat exchange tube, the first groove 21 on the top of the first-stage spiral outer fin 2 forms an uneven wing tip 211 structure, which is beneficial to destroy the surface tension of the condensed liquid film and make the liquid film Thinning, reducing thermal resistance, thereby achieving the effect of reducing the thickness of the liquid film and improving the condensation heat transfer. At the same time, the complex three-dimensional structure also increases the heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com