Fracture traction reduction device

A traction reset and traction component technology, applied in the direction of fixator, external fixator, etc., can solve the problems of inability to adjust movement at any angle and position, poor flexibility in multi-angle adjustment, etc. High stability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

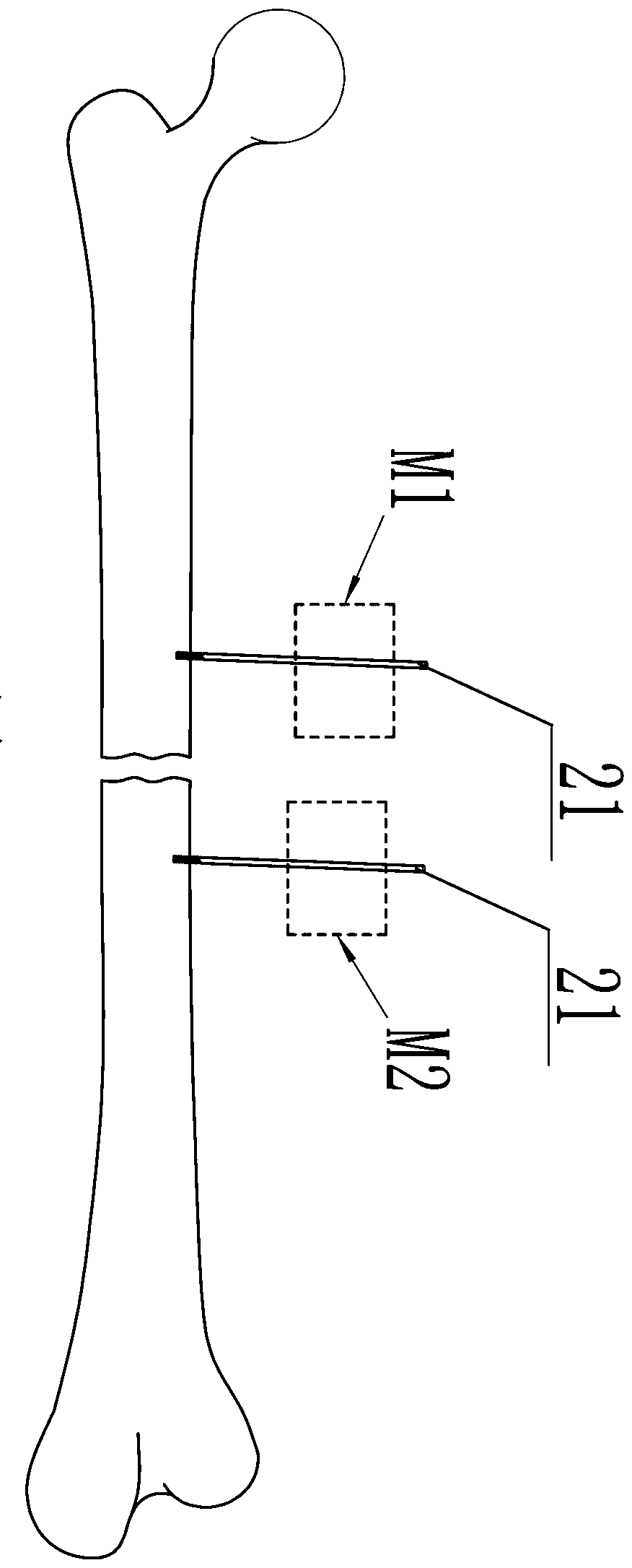

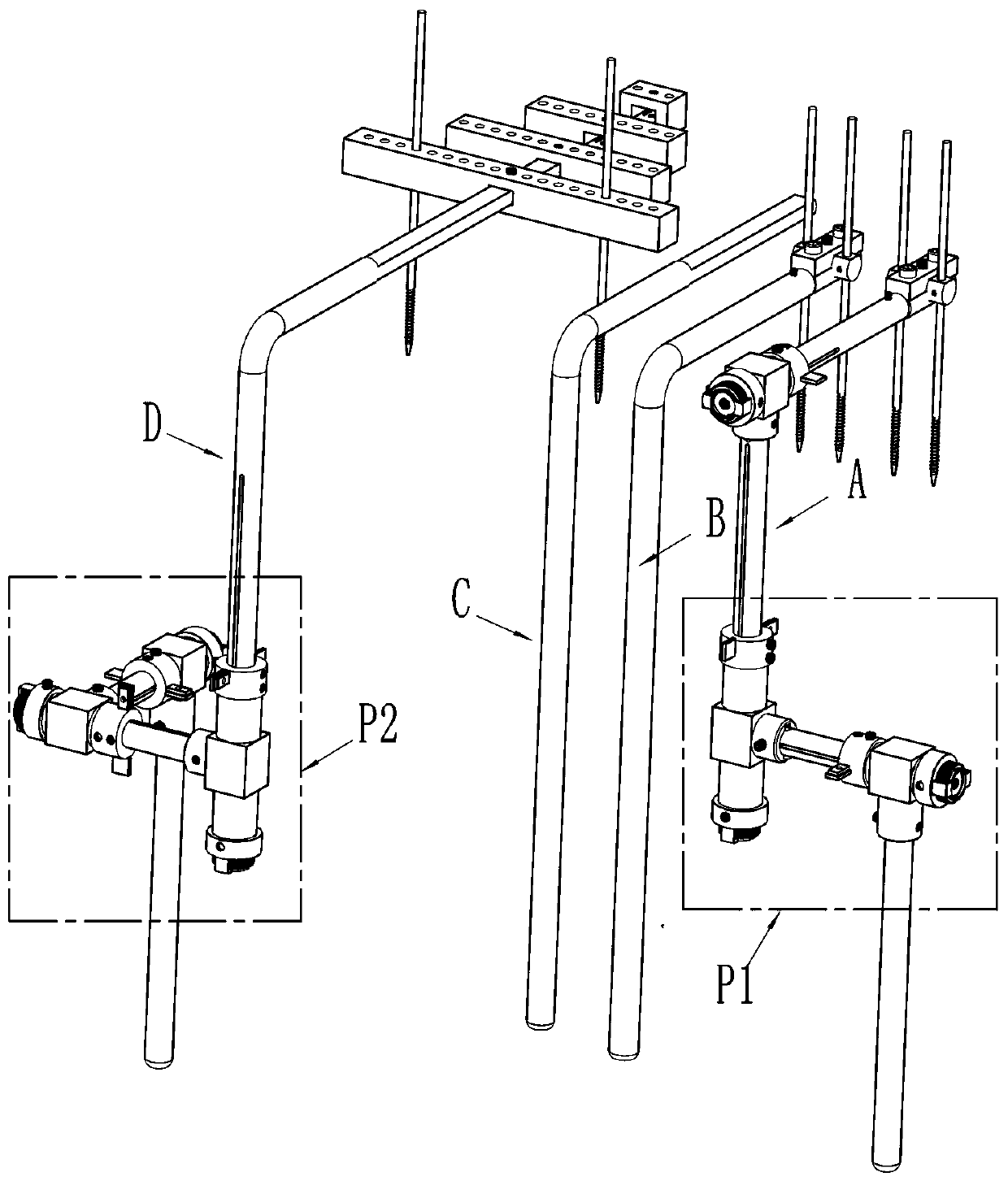

[0038] Embodiment 1: In this embodiment, the active adjustment mechanism is adopted as traction assembly A, and the passive adjustment mechanism is also adopted as traction assembly A.

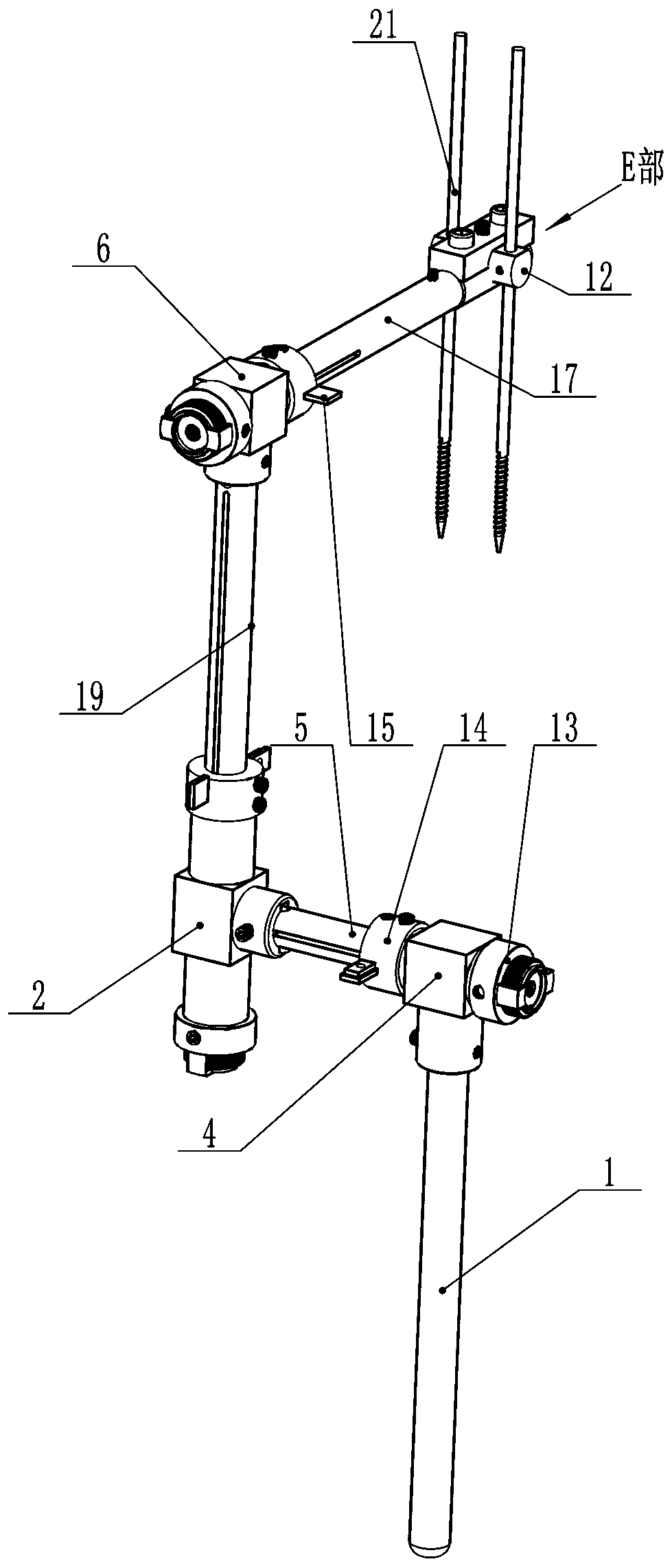

[0039] Such as image 3 As shown, the traction assembly A includes a three-dimensional adjustment mechanism P1, the bottom of the three-dimensional adjustment mechanism one is fixed, and the control end of the three-dimensional adjustment mechanism one fixes the Kirschner wire one. Specifically, the three-dimensional adjustment mechanism includes a first-level rod, that is, the vertical rod 1 , a second-level rod, that is, the longitudinal axis 5 , a third-level rod, that is, the vertical shaft 19 , and a fourth-level rod, that is, the horizontal shaft 17 . The upright pole is fixed on the bed frame or support (carrier) by the fixing parts, and the fixing parts are common locking parts in the field, or are fixed by more than two crossing bolts. Such as image 3 Among them, the upper end of t...

Embodiment 2

[0042] Embodiment 2: In this embodiment, the first Kirschner wire is fixedly installed as the traction assembly A by the active adjustment mechanism, and the second Kirschner wire is also fixedly installed by the traction assembly B by the passive adjustment mechanism.

[0043] The structure of the traction assembly A is the same as that of the traction assembly A in Embodiment 1, and will not be described in detail. The traction assembly B includes a vertical rod, the upper end of the vertical rod is connected with a flat rod in a horizontal direction, and the end of the flat rod is provided with an angle adjustment mechanism. The adjustment part fixes the two Kirschner wires.

[0044] The angle adjustment mechanism is located at the end of the horizontal axis, such as Figure 7-Figure 13 As shown, the angle adjustment mechanism is provided with a rotating Kirschner wire seat 12 at the end of the corresponding rod (ie, the horizontal axis) for installing the Kirschner wire. ...

Embodiment 3

[0045] Embodiment 3: In this embodiment, the first Kirschner wire is fixedly installed as the traction assembly A by the active adjustment mechanism, and the second Kirschner wire is also fixedly installed by the traction assembly B by the passive adjustment mechanism.

[0046] The structure of the traction assembly A is the same as that of the traction assembly A in Embodiment 1, and will not be described in detail. The traction assembly B includes a vertical rod, the upper end of the vertical rod is connected with a flat rod in a horizontal direction, and the end of the flat rod is provided with an angle adjustment mechanism. The adjustment part fixes the two Kirschner wires.

[0047] The angle adjustment mechanism is located at the end of the horizontal axis, and the angle adjustment mechanism is provided with a rotating and rotating Kirschner wire seat 12 at the end of the corresponding rod, such as Figure 17 As shown, the slidable and rotatable Kirschner wire holder 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com