Full-automatic male pin solder cup milling machine

A milling machine, fully automatic technology, applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of low efficiency and labor time, and achieve the effect of improving work efficiency, high practicability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

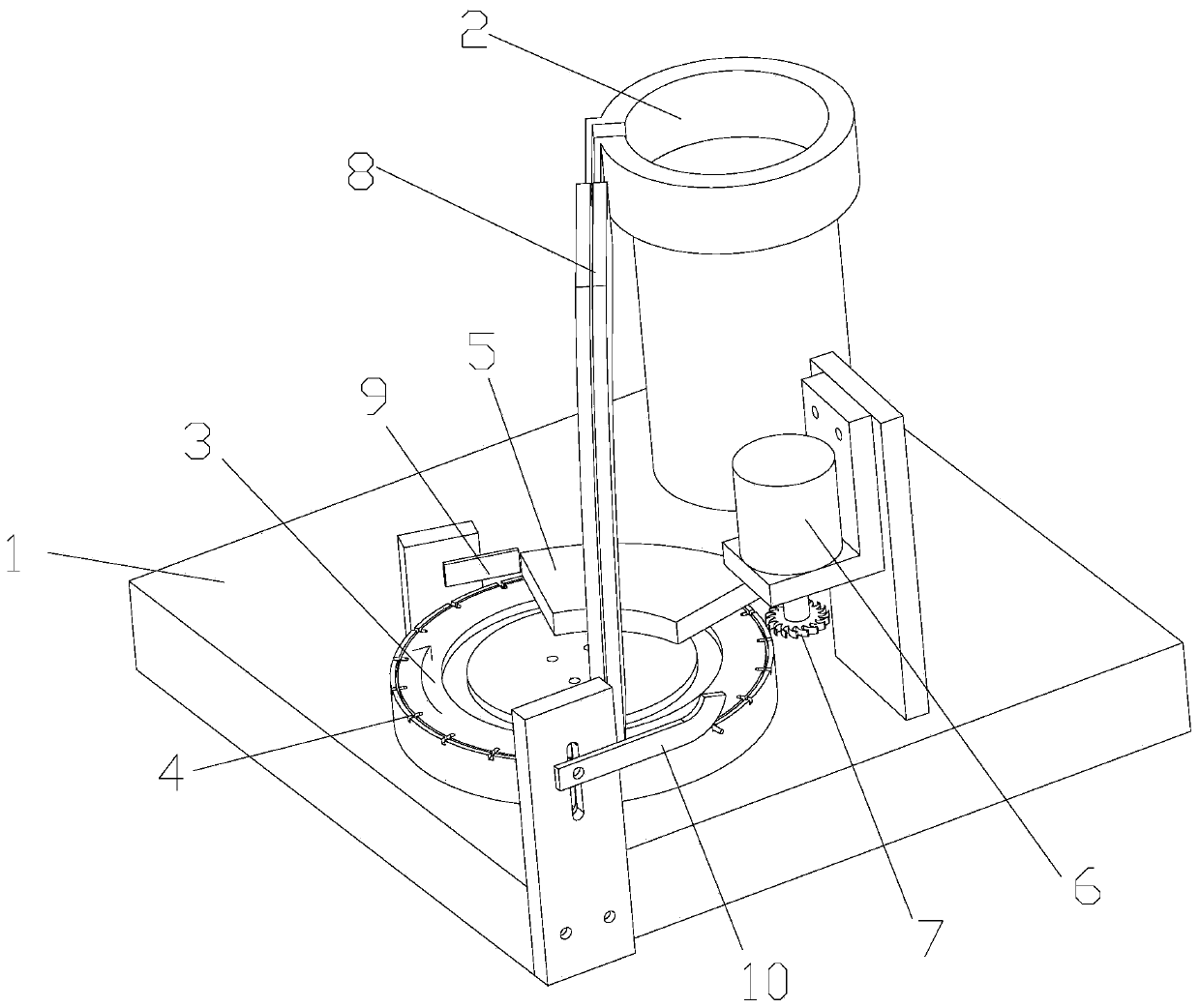

[0025] Example: such as figure 1 As shown, a fully automatic male pin welding cup milling machine includes a base 1 on which a vibrating plate 2 and a rotating disc 3 are arranged. The vibrating disc 2 and the rotating disc 3 are connected through an arc track 8, and the arc The feed port of the track 8 is located in the vibrating plate 2, and the discharge port of the arc track 8 is close to the round edge of the upper surface of the rotating disc 3, and at the same time, it is evenly circled around the round edge of the upper surface of the rotating disc 3. A number of card slots 4 are provided; one side of the rotating disc 3 is provided with a milling device, the milling device includes a cutter 7, a rotating shaft and a rotating motor 6, the cutter 7 is connected to the rotating motor 6 through a rotating shaft, and the cutter 7 and the card slot 4 are in the same Horizontal position; the main working process of the fully automatic male pin welding cup milling machine de...

Embodiment approach

[0027] The shape of the fixed disk 5 is a non-circular arc shape, and the position of the fixed disk 5 corresponds to the position of the milling device; the function of the fixed disk 5 is to position and fix the male needle at the milling position, Therefore, the shape and size of the fixed disk 5 need not be the same as that of the rotating disk 3 , it only needs to be a non-circular arc shape.

[0028] A positioning plate 9 is arranged on one side of the rotating disk 3, and the positioning plate 9 and the slot 4 are at the same horizontal position. According to the running track of the slot 4 on the rotating disk 3, the positioning plate 9 is located in the upper direction of the tool 7; The function of the positioning plate 9 is that when the male needle enters the slot 4, the position may not be correct. The positioning plate 9 can position the male pin in the slot 4 in time, because the positioning work needs to be done before the milling work, so The positioning plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com