Obstacle-crossing wall-climbing robot combined variable magnetic force attraction module

A magnetic adsorption, composite technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problem of insufficient adjustment of magnet adsorption force, and achieve the effect of improving the utilization rate of magnet strength, improving the distribution of magnetic induction lines, and improving stability and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

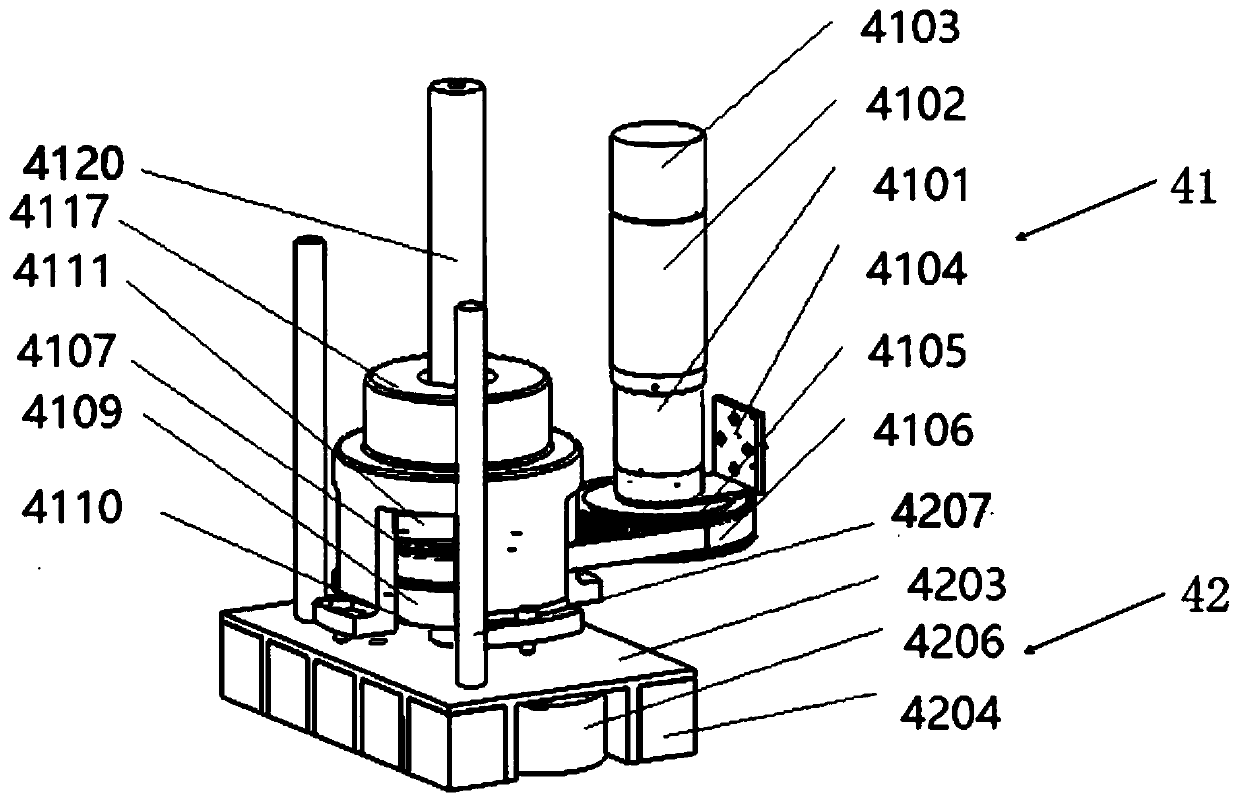

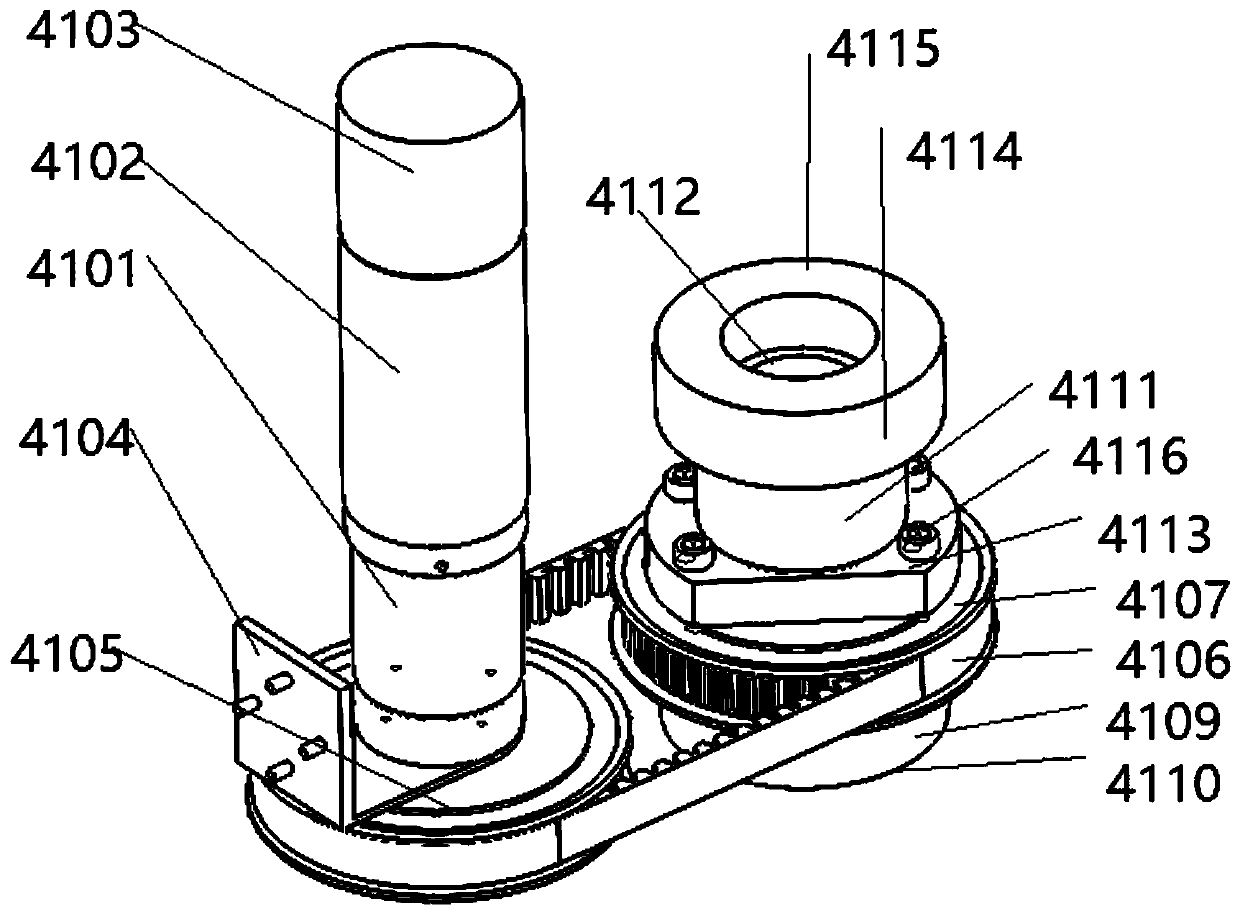

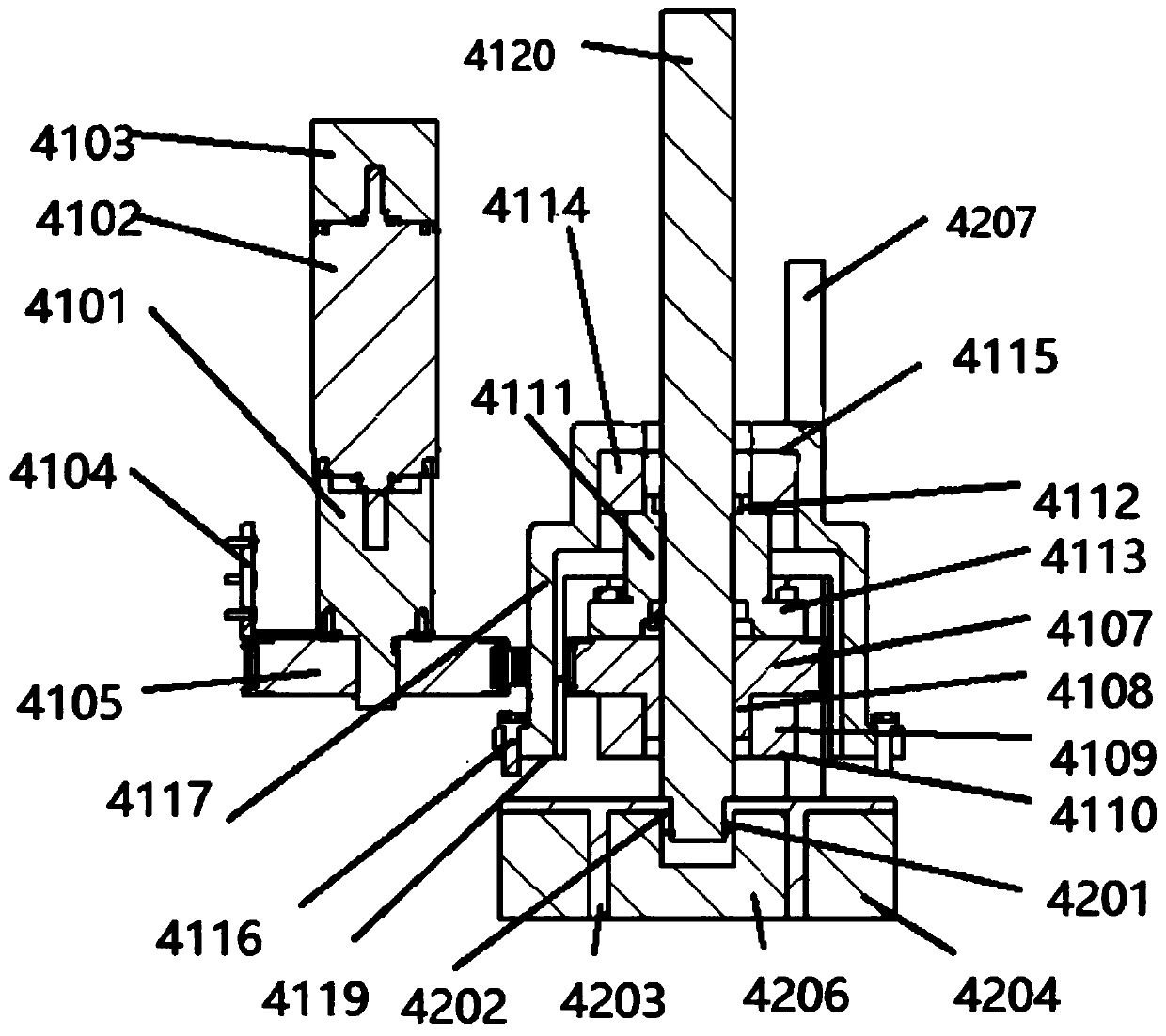

[0043] The composite variable magnetic adsorption module of the obstacle-climbing robot in this embodiment is applied to the obstacle-climbing robot used on large metal facades such as ships and oil storage tanks. The maximum height of obstacles on the facade is 100mm, and the friction coefficient is 0.4. Introduction to the technical indicators of the robot: the load (additional body) is 50kg, the obstacle height can be surmounted by 100mm, it can adapt to a certain wall curvature, and it can complete the derusting operation of large metal facades. Figure 8-9 It is a schematic diagram of the working process of an obstacle-climbing robot robot that installs an example of the compound variable magnetic force adsorption module of the obstacle-climbing robot of the present invention, Figure 10 The robot in the robot includes three sets of frames 1, six sets of wheel-foot composite drive modules 2, frame connection modules 3, three sets of composite magnetic variable adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com