Wood panel drilling device convenient to control punching spacing

A technology of drilling device and wood plate, applied in fixed drilling machine and other directions, can solve the problems of low precision and inconvenient control of the distance between two holes, achieve high precision, easy to control the distance of drilling, realize front and rear, left and right moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

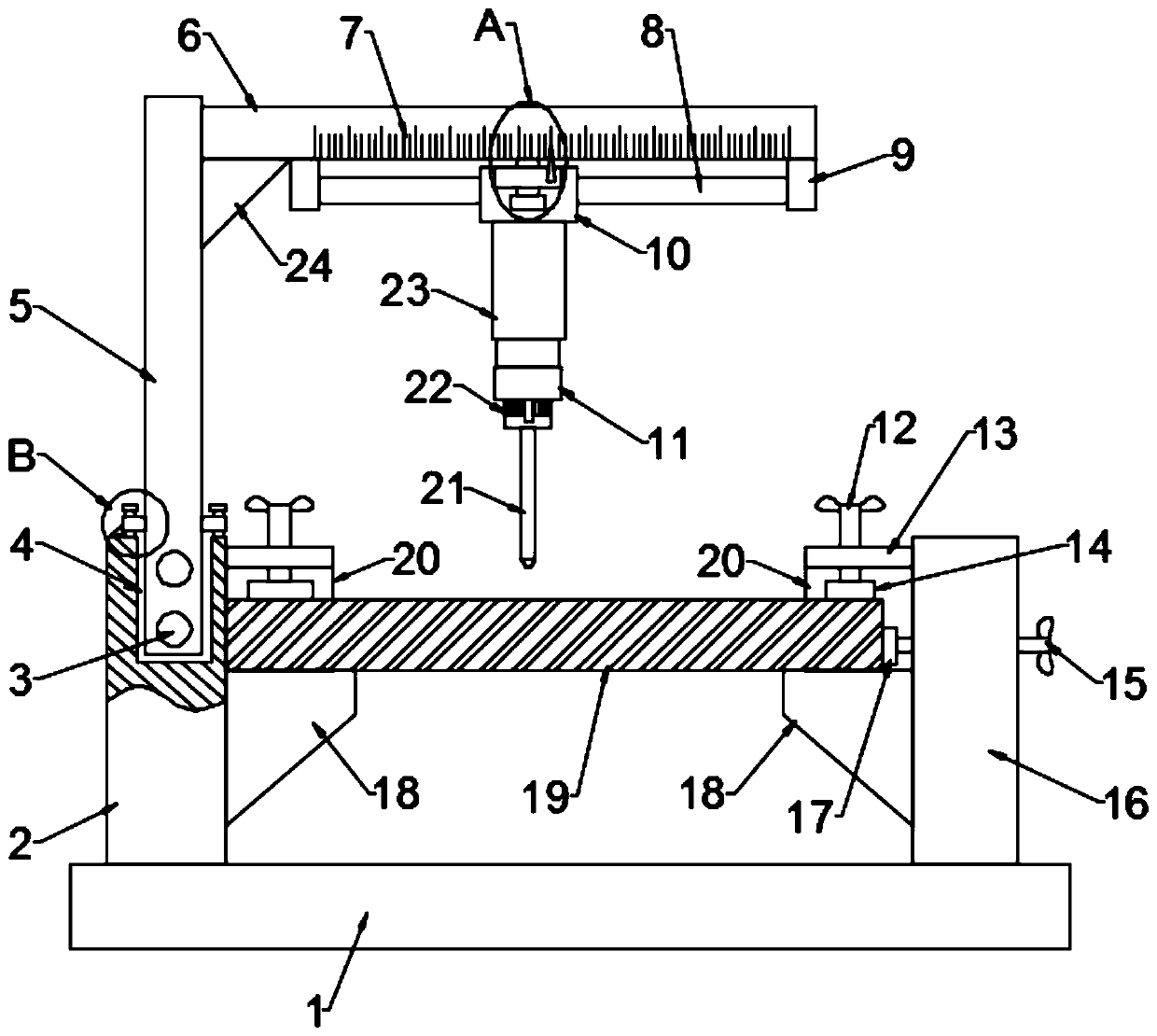

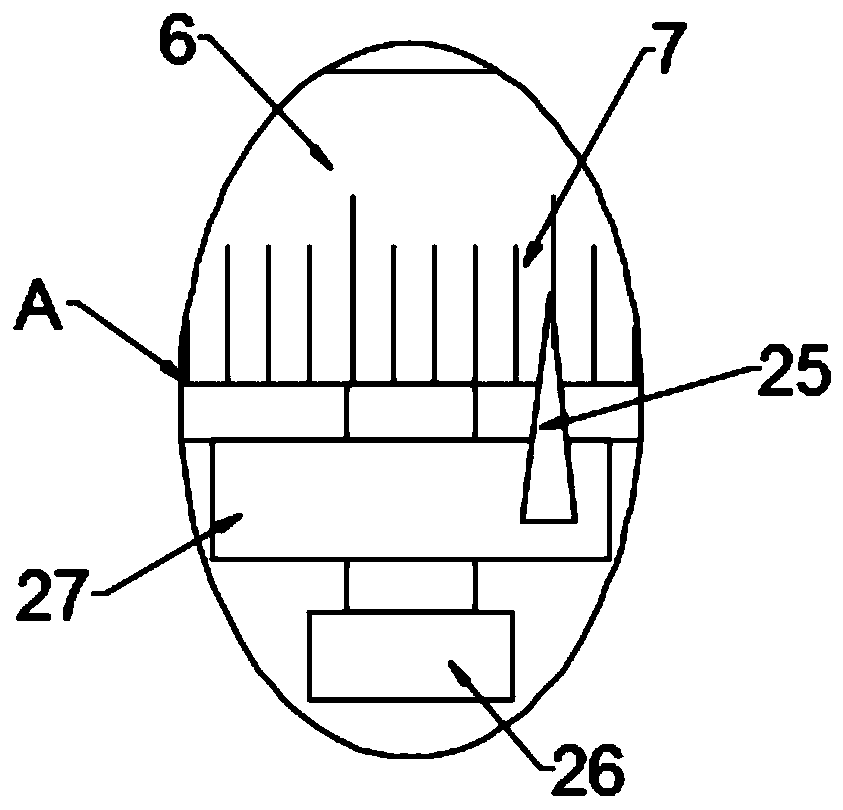

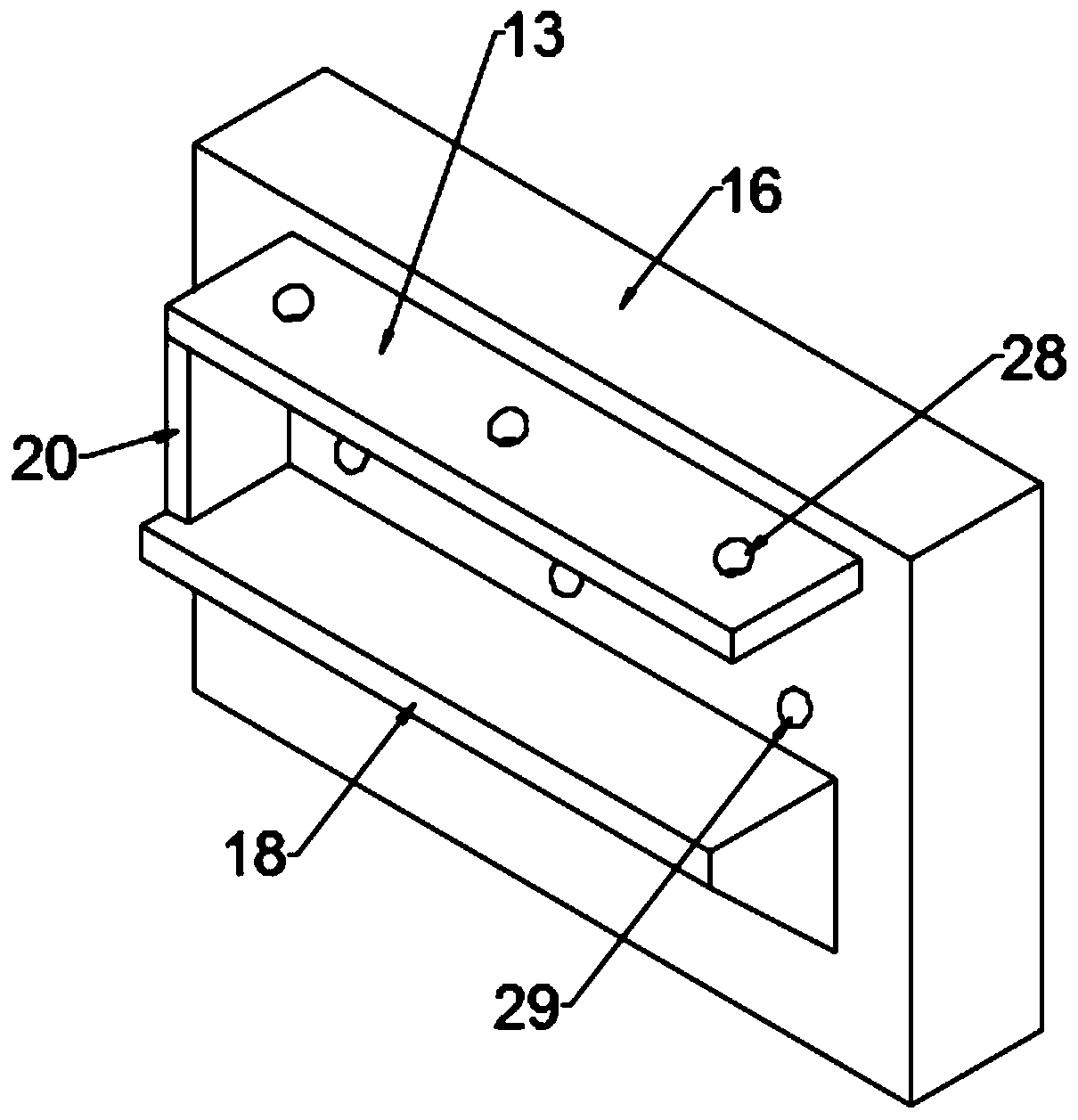

[0033] see Figure 1-5 , in the embodiment of the present invention, a kind of wood board drilling device that is convenient to control punching pitch, comprises base plate 1 and motor 22, and the output shaft of motor 22 is connected with drill rod 21; Said base plate 1 is provided with left side plate 2 And right side plate 16, supporting plate 18 and top plate 13 are all installed on the inboard surface of left side plate 2 and right side plate 16, be provided with tailgate 20 between the rear end of supporting plate 18 and top plate 13, so The top plate 13 is provided with a top extruding assembly, and the right side plate 16 is provided with a side extruding assembly; from the front opening of the top plate 13 and the supporting plate 18, the wooden board 19 to be punched is put into the supporting plate 18 and make the rear side of the wooden board 19 contact with the tailgate 20, press the wooden board 19 to the left through the side extrusion assembly, make the left si...

Embodiment 2

[0049] see Figure 6 , in the embodiment of the present invention, a kind of plank drilling device that is convenient to control the punching pitch, differs from embodiment 1 in that the bottom of the bottom plate 1 is provided with a wheel seat 38 and a horizontal plate 39, and the bottom of the wheel seat 38 Moving wheel 37 is installed, and strut bar 35 is threadedly installed on cross plate 39, and the bottom rotation of support bar 35 is provided with support foot 36, and the side of left side plate 2 is fixed with push rod 34; Screw thread fits, and rotating support bar 35 can drive support pin 36 to move up and down, utilize support pin 36 to be able to support the wood panel drilling device that this is convenient to control punching pitch when punching, after punching is finished, rotate support bar 35 to make support pin 36 breaks away from ground, is convenient to move this wood panel drilling device that is convenient to control punching pitch by support bar 35 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com