Intelligent cargo pickup transferring system for terminal warehouse

A warehouse and intelligent technology, applied in the field of intelligent warehouses, can solve problems such as difficulty in improving work efficiency, failure to obtain scattered goods, and failure to obtain target goods, etc., to achieve the effect of reducing manual participation, saving manual packaging operations, and reducing the rate of manual errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

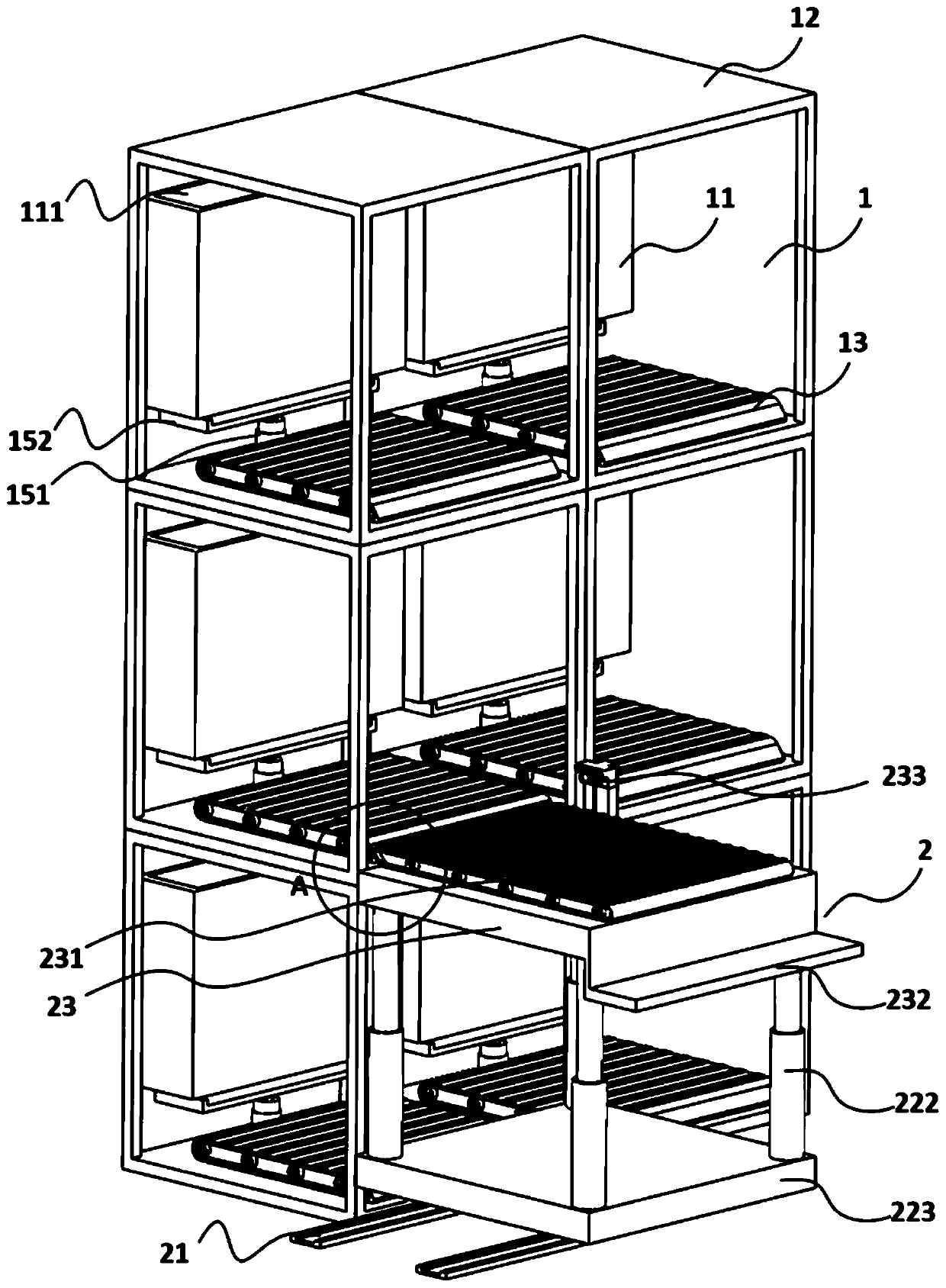

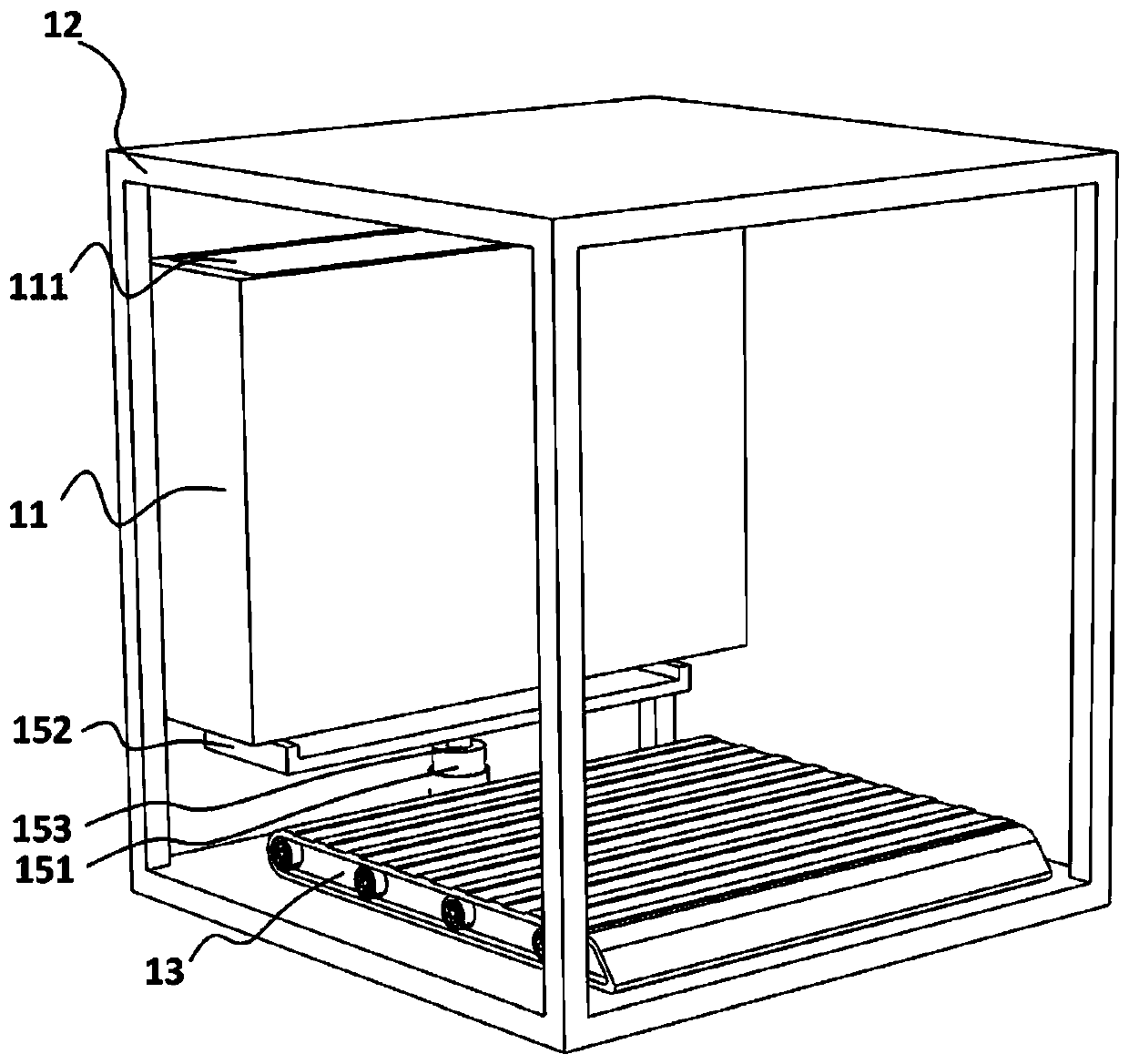

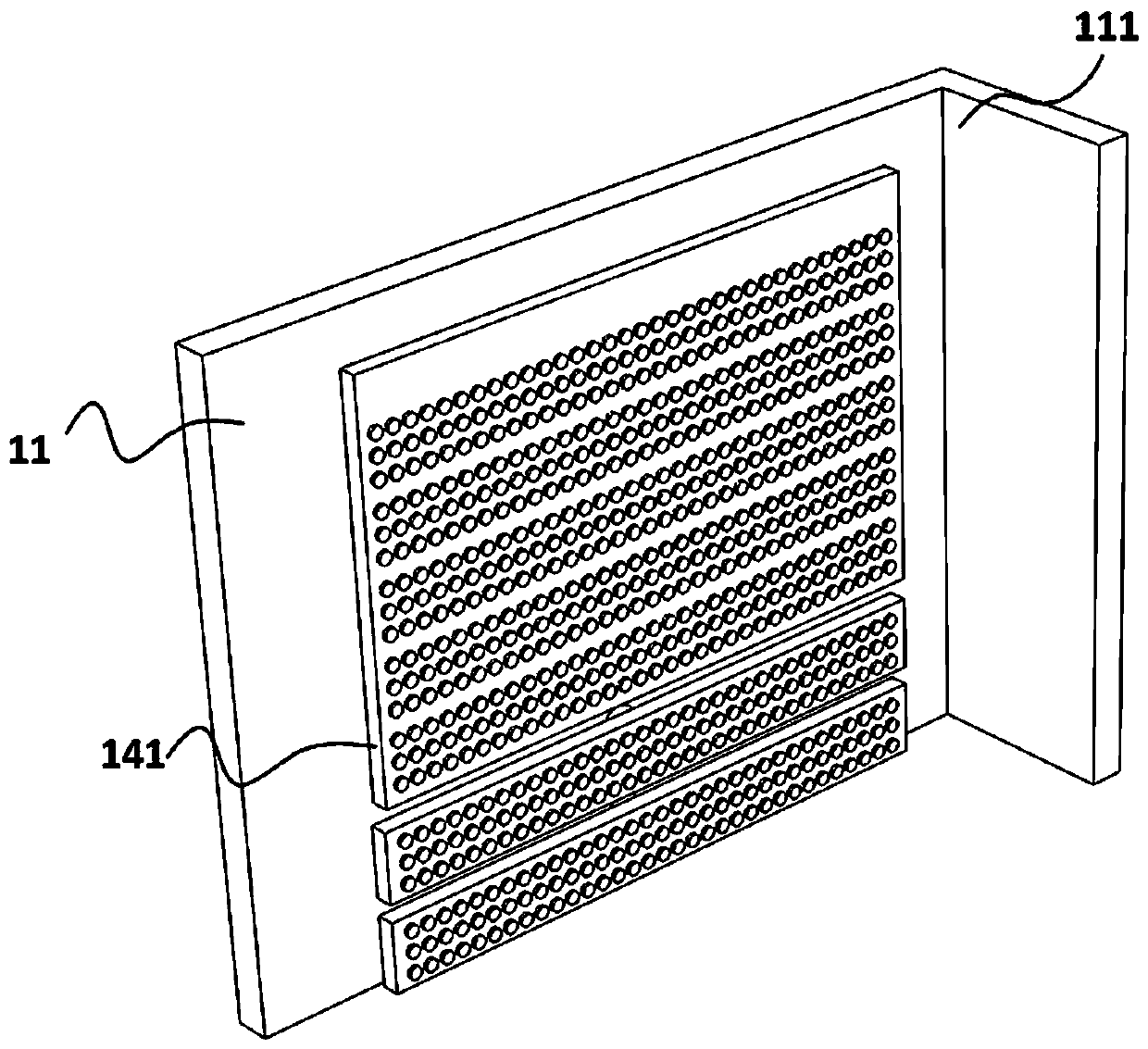

[0068] refer to Figure 1-7 .

[0069] This embodiment provides an intelligent pick-up and transfer system for terminal warehouses, including: a storage system 1 and a transfer system 2 . It also includes a processor 3 connected to the storage system 1 and the transfer system 2 and a cloud server 4 communicating with the processor 3 .

[0070] The cloud server 4 is connected to the processor 3, and the cloud server 4 can be used to receive remote orders from users or merchants. After receiving the order, the cloud server 4 outputs the corresponding order to the corresponding processor 3 according to the order information.

[0071] There can be at least one cloud server 4, and the processor 3 can be the processor 3 corresponding to the current warehouse, and a single warehouse corresponds to one or more processors 3, and the processor 3 intelligently manages the corresponding warehouse. If a single warehouse corresponds to multiple processors 3, the warehouse is divided into ...

Embodiment 2

[0121] refer to Figure 8 .

[0122] This embodiment is basically the same as the first embodiment above, except that, as a preferred mode of this embodiment, the second transfer belt 231 includes a weight comparison device 5 connected to the processor 3 .

[0123] The weight comparison device 5 is used to obtain the weight of the articles on the second transfer belt 231 , specifically, the weight comparison device 5 can be a pressure sensing device, and obtain the weight of the articles by obtaining the pressure on the second transfer belt 231 .

[0124] The weight comparison device 5 is arranged under the crawler belt of the second transfer belt 231 , and is used to monitor the weight of the items on the surface of the second transfer belt 231 , and output the weight of the items to the processor 3 .

[0125] The weight comparison device 5 is arranged under the crawler belt of the second transfer belt 231 , and if any item is placed on the second transfer belt 231 , the wei...

Embodiment 3

[0135] refer to Figure 9-10 .

[0136] This embodiment is basically the same as the above-mentioned embodiment, the difference is that, as a preferred mode of this embodiment, the storage unit 232 also includes a first circulation rack 61, a second circulation rack 62, a carrier frame 63, and a mobile adsorption device 64 .

[0137] The first circulating rack 61 and the second circulating rack 62 are evenly divided into upper and lower layers and are all circulating crawlers 611. The first circulating rack 61 is used to store empty storage boxes, and the second circulating rack 62 is used to store storage for placing items. box. The first circulation rack 61 and the second circulation rack 62 are arranged below the transfer platform 23 and are respectively connected to the processor 3, and the processor 3 drives the first circulation rack 61 and / or the second circulation rack 62 to rotate forward and / or reversely .

[0138] The first circulation rack 61 and the second cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com