A kind of edible coating film and preparation method thereof

A technology of coating film and edible properties, applied in the field of edible coating film and its preparation, to achieve the effect of improving film-forming characteristics, compact spatial structure, and strong thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

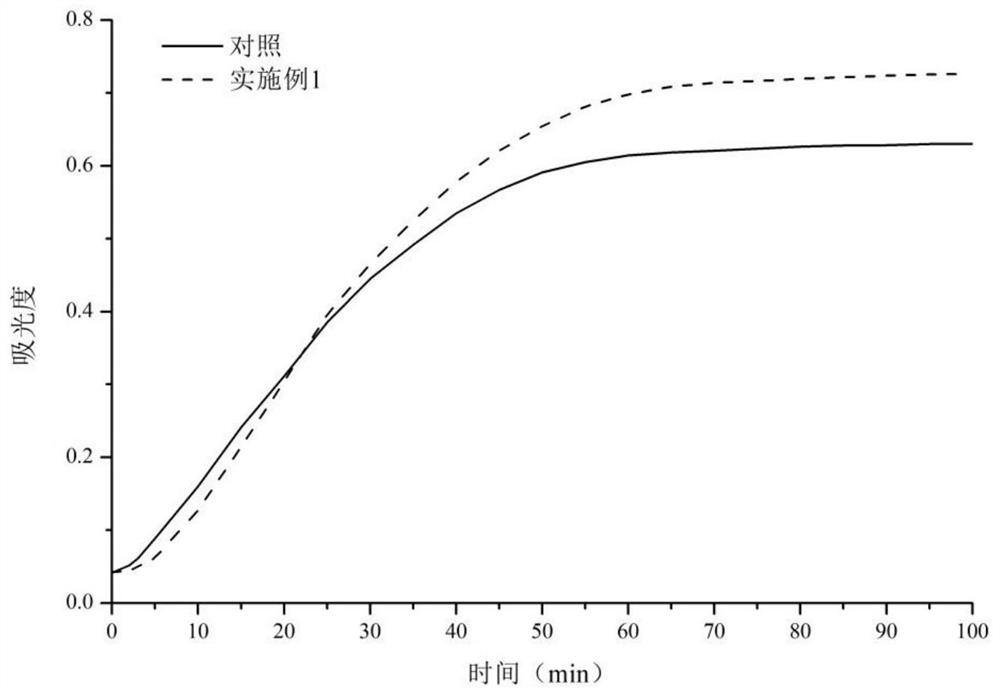

Embodiment 1

[0036] A kind of preparation method of edible coating film, comprises the following steps:

[0037] (1) Grass carp swim bladders were degreased and washed with water until neutral, added 0.5M acetic acid (1:10, w / v), 0.1% (w / v) 3000U / mg pepsin for 24 hours, centrifuged at 5000r / min for 20min, and Add pre-cooled sodium chloride to the supernatant for salting out, let it stand for 4 hours, then centrifuge to get the precipitate, repeat the salting out operation of the supernatant, dissolve the combined precipitate with 10 times the volume of 0.5% M acetic acid, dialyze, vacuum freeze-dry and store at -20°C Stand by to obtain the grass carp swim bladder collagen.

[0038] (2) After the grass carp meat is minced, add 10 times the volume of pre-cooled sodium chloride solution (50mmol / L) to homogenate, place in an ice bath and stir for 30min, filter with gauze, centrifuge at 8000r / min for 15min, take the precipitate and The grass carp myofibrillar protein was obtained by adding pre...

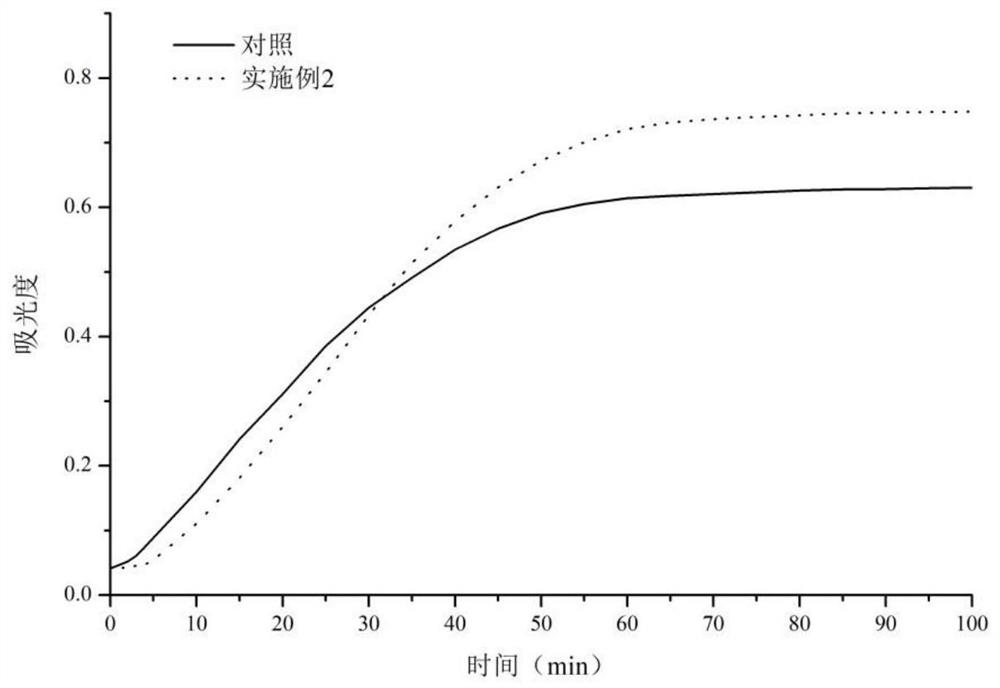

Embodiment 2

[0051] A kind of preparation method of edible coating film, comprises the following steps:

[0052] (1) After the grass carp swim bladder is degreased, it is fully washed with water until it becomes neutral, and 0.5M acetic acid (1:10, w / v), 0.1% (w / v) 3000U / mg pepsin is added to react for 36h, centrifuged at 5000r / min for 20min, and Add pre-cooled sodium chloride to the supernatant for salting out, let it stand for 4 hours, then centrifuge to get the precipitate, repeat the salting out operation of the supernatant, dissolve the combined precipitate with 10 times the volume of 0.5% M acetic acid, dialyze, vacuum freeze-dry and store at -20°C stand-by.

[0053] (2) Extraction of grass carp myofibrillar protein: After the grass carp meat is minced, add 10 times the volume of pre-cooled sodium chloride solution (60mmol / L) to homogenate, place it in an ice bath and stir for 30min, filter with gauze, 8000r / L Centrifuge at 1 min for 15 min, take the precipitate, add pre-cooled sodi...

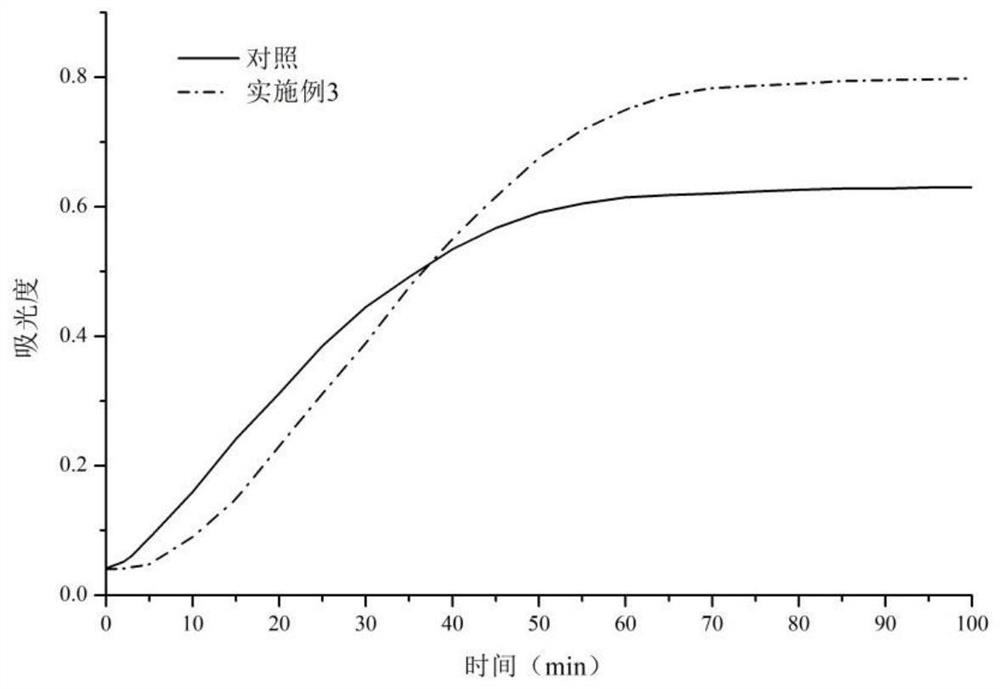

Embodiment 3

[0066] A kind of preparation method of edible coating film, comprises the following steps:

[0067] (1) Grass carp swim bladders were degreased and washed with water until neutral, added 0.5M acetic acid (1:10, w / v) and 0.1% (w / v) 3000U / mg pepsin to react for 48h, centrifuged at 5000r / min for 20min, and Add pre-cooled sodium chloride to the supernatant for salting out, let it stand for 4 hours, and then centrifuge to collect the precipitate. use.

[0068] (2) Extraction of grass carp myofibrillar protein: After the grass carp meat is minced, add 10 times the volume of pre-cooled sodium chloride solution (70mmol / L) to homogenate, place it in an ice bath and stir for 30min, filter with gauze, 8000r / L Centrifuge at 1 min for 15 min, take the precipitate, add pre-cooled sodium chloride solution to homogenate, centrifuge, and cycle wash 3 times, the obtained precipitate is grass carp myofibrillar protein.

[0069] (3) Enzymatic hydrolysis of grass carp myofibrillar protein: Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| emulsifying | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com