Palladium vanadium precision high-resistance alloy and preparation method thereof

A high-resistance alloy and vanadium alloy technology, applied in the field of metal materials, can solve the problems that have not been reported in the literature, and achieve the effects of excellent comprehensive performance, increased resistivity, and reduced resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

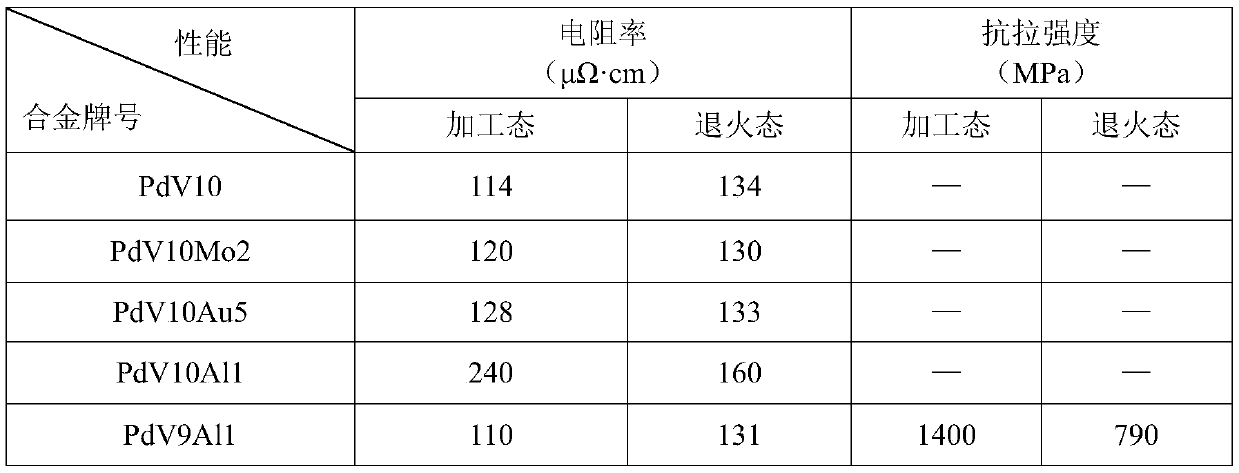

Image

Examples

Embodiment 1

[0023] Each component of the alloy is formulated according to the mass percentage of 29% V, 2% Cr, 1% Ru, 1% Al, and the rest of Pd; it is melted with a high-purity alumina crucible and a high-frequency induction furnace, and the melting chamber is first melted Vacuum to 0.1×10 -4 Pa, filled with high-purity argon (99.999%, volume fraction) to positive pressure, the alloy is fully degassed in the molten state and cast in a crystallization mold, and the ingot is subjected to a homogenization heat treatment at 1200 ° C for 5 hours under argon protection; after 1200 ℃ Forging, rolling, thick wire drawing, and intermediate annealing adopt 1000 ℃ heat preservation for 50 minutes to quickly cool out of the furnace, multi-mode fine drawing to prepare wires with a diameter of Φ0.030mm; carry out 600 ℃ argon protection, heat preservation for 60 minutes and slow down with the furnace Cold short-range order transformation heat treatment.

[0024] Properties of PdV29Cr2Ru1Al1 alloy: resi...

Embodiment 2

[0026] Each component of the alloy is formulated according to the ingredients of 31% V, 2% Cr, 2% Al, and the balance of Pd; it is melted with a high-purity alumina crucible and a high-frequency induction furnace, and the melting chamber is first evacuated to 0.2×10 -4 Pa, filled with high-purity argon (99.999%, volume fraction) to positive pressure, the alloy is fully degassed in the molten state and cast in a crystallization mold, and the ingot is subjected to a homogenization heat treatment at 1250 ° C for 5 hours under argon protection; after 1200 ℃ Forging, rolling, drawing of thick wire, and intermediate annealing are carried out with 1000 ℃ argon protection and heat preservation for 60 minutes. Short-range orderly transformation heat treatment with furnace slow cooling in minutes.

[0027] Properties of PdV31Cr2Al2 alloy: resistivity 203.8μΩ·cm, tensile strength 1640MPa, temperature coefficient of resistance 43.6ppm / ℃.

Embodiment 3

[0029] Each component of the alloy is formulated according to the ingredients of 32% V, 3% Al, 1% Ru, and the balance of Pd; it is melted with a high-purity alumina crucible and a high-frequency induction furnace, and the melting chamber is first evacuated to 0.1×10 -4 Pa, filled with high-purity argon (99.999%, volume fraction) to positive pressure, the alloy is fully degassed in the molten state and cast in a crystallization mold, and the ingot is subjected to a homogenization heat treatment at 1300 ° C for 5 hours under argon protection; after 1200 ℃ Forging, rolling, thick wire drawing, and intermediate annealing are carried out with 1000 ℃ argon protection and heat preservation for 70 minutes, quick cooling, multi-mode fine drawing, and a wire material with a diameter of Φ0.04mm is prepared; 700 ℃ argon protection and heat preservation for 60 Short-range orderly transformation heat treatment with furnace slow cooling in minutes.

[0030] Properties of PdV32Al3Ru1 alloy: r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| temperature coefficient of resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com