Modular differential settlement accurate control device

It is a technology of precise control and differential settlement, which is applied to the field foundation soil survey, roads, roads, etc., and can solve the problems such as the inability to simulate the deformation response of weak strata and the uneven settlement of the subgrade surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

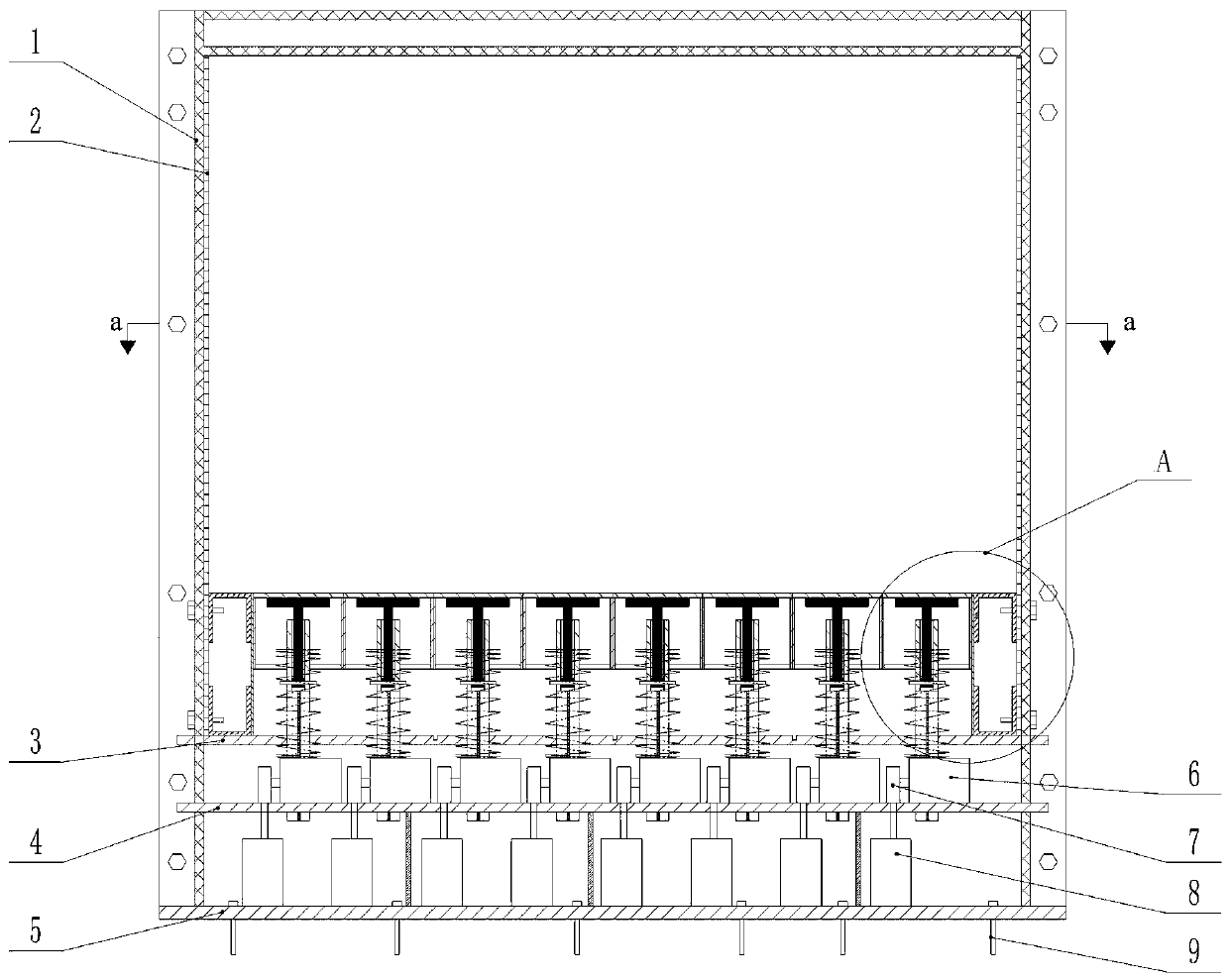

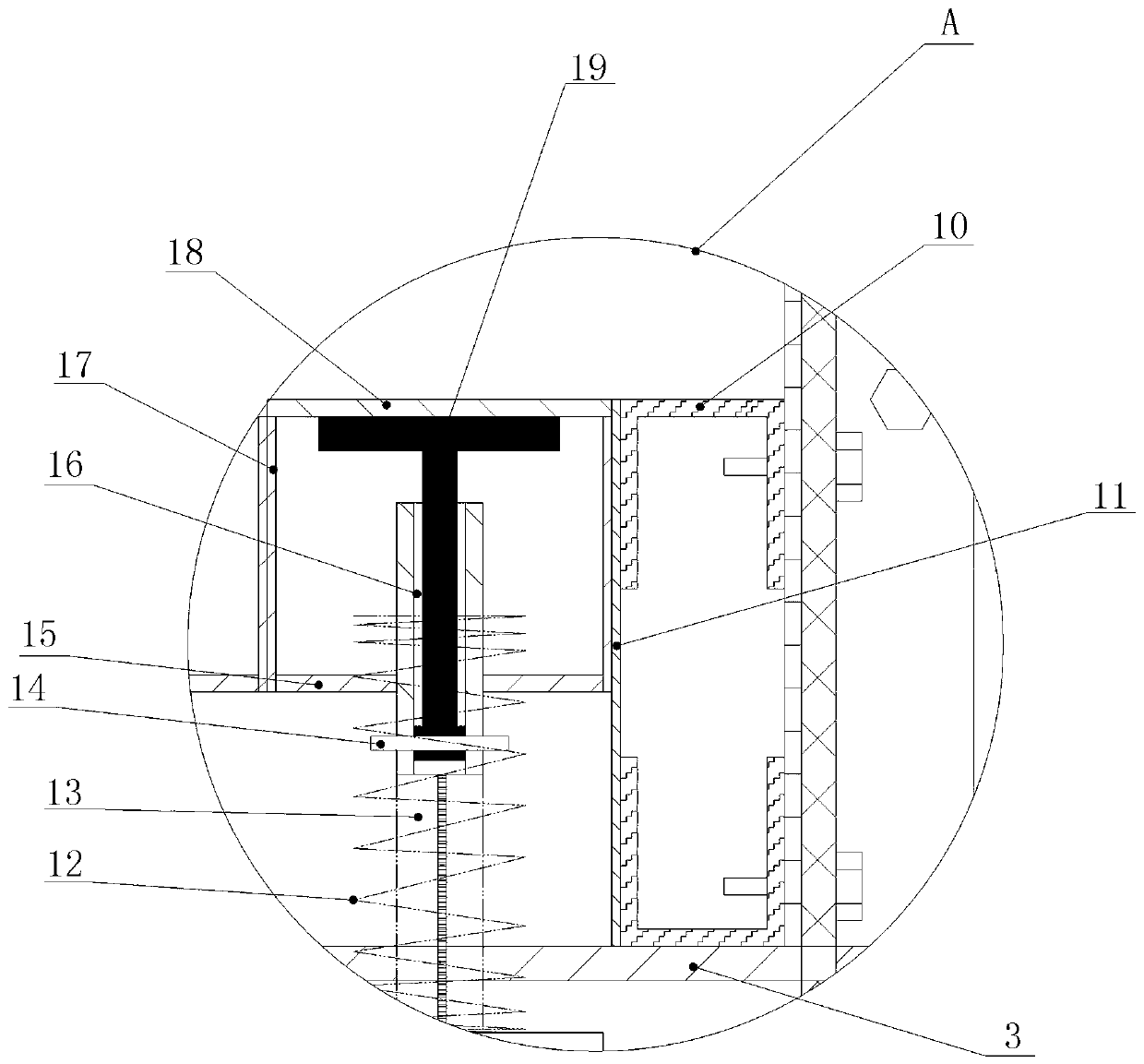

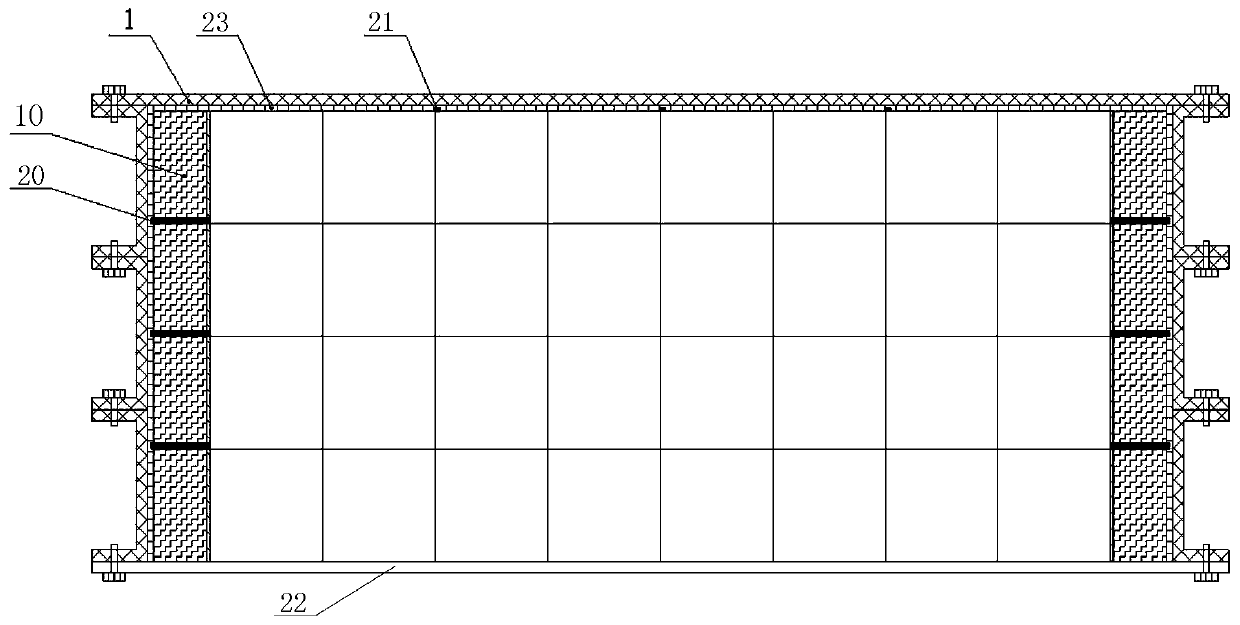

[0034] Such as figure 1 , figure 2 , image 3 Shown:

[0035] A modular differential settlement precision control device, including a model box frame 1, the size of the model box frame 1 (length × width × height) is 2000mm × 850mm × 2000mm, and the bottom plate 5 of the model box frame 1 is provided with 8× 4 variable speed motors 8, the first support plate 4 is fixed on the top of the variable speed motor 8, and the upper surface of the first support plate 4 is correspondingly provided with 8×4 screw lifters 6, and the output shaft of each variable speed motor 8 passes through the first support The plate 4 is connected to the corresponding screw lifter 6 through the diverter 7, the second support plate 3 is fixed above the screw lifter 6, the upper surface of the second support plate 3 is covered with a test box 2 with upper and lower ends opening around it, and the test box 2 The size (length×width×height) is 1800mm×800mm×1200mm. Two rows of side piers 10 are fixed on bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com