Construction method of wading open cut foundation pit combined type steel sheet pile cofferdam

A technology of steel sheet pile cofferdam and construction method, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems affecting the construction quality, water insulation effect and stability of steel sheet pile cofferdam, the difficulty of airtight water insulation, and no dynamic stability involved. Control and other issues to achieve the effect of reuse, improve quality, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principles of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

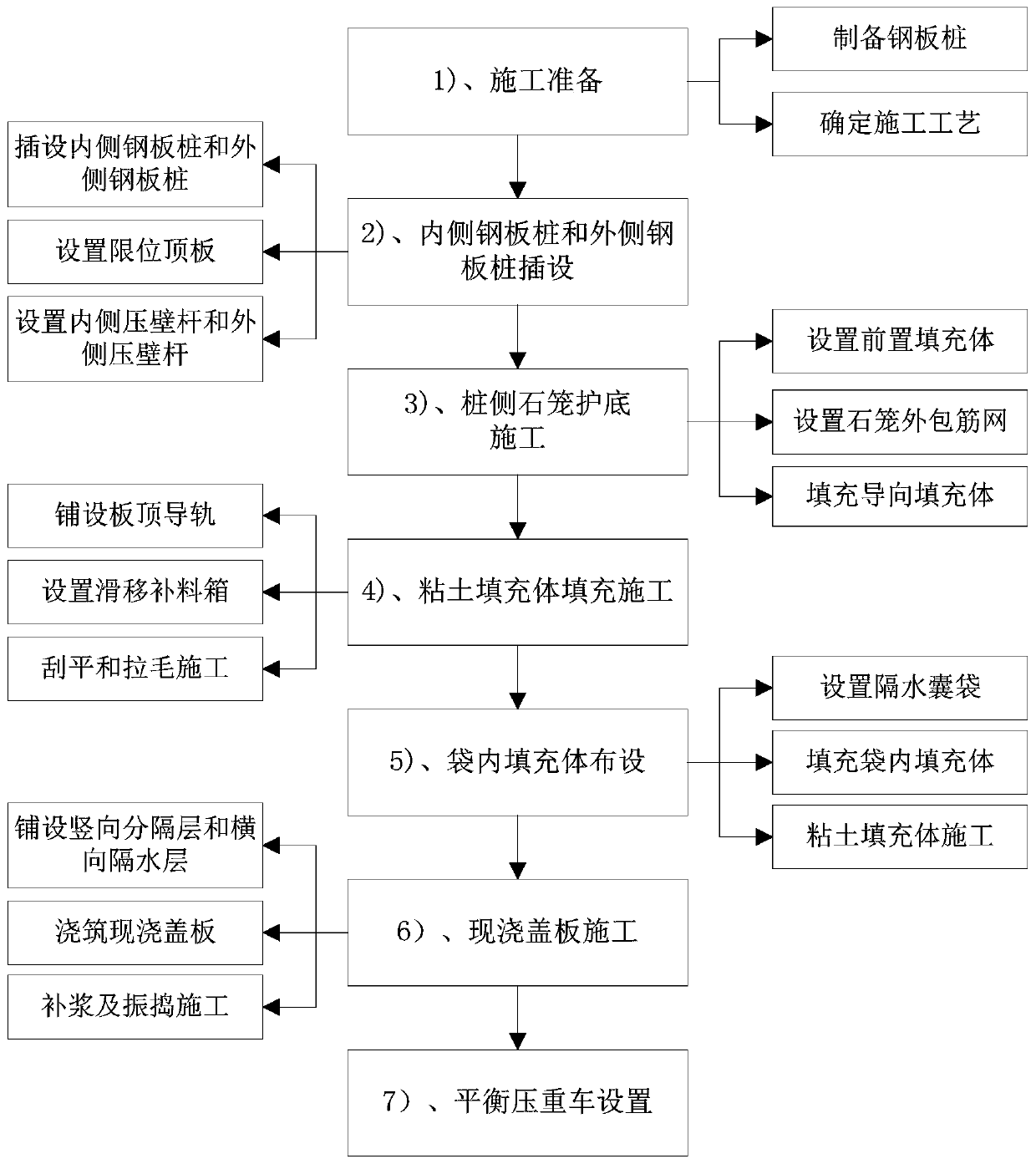

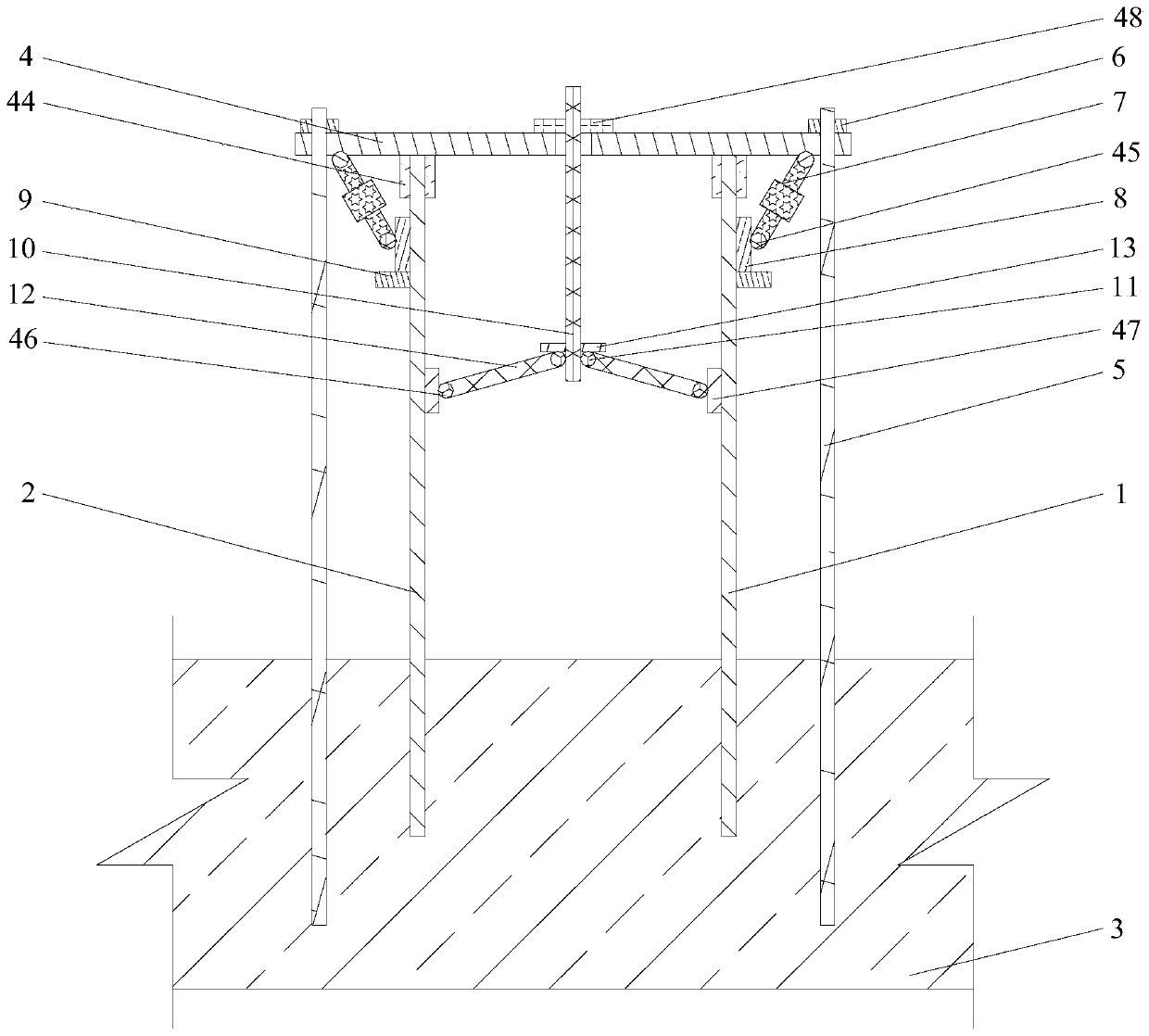

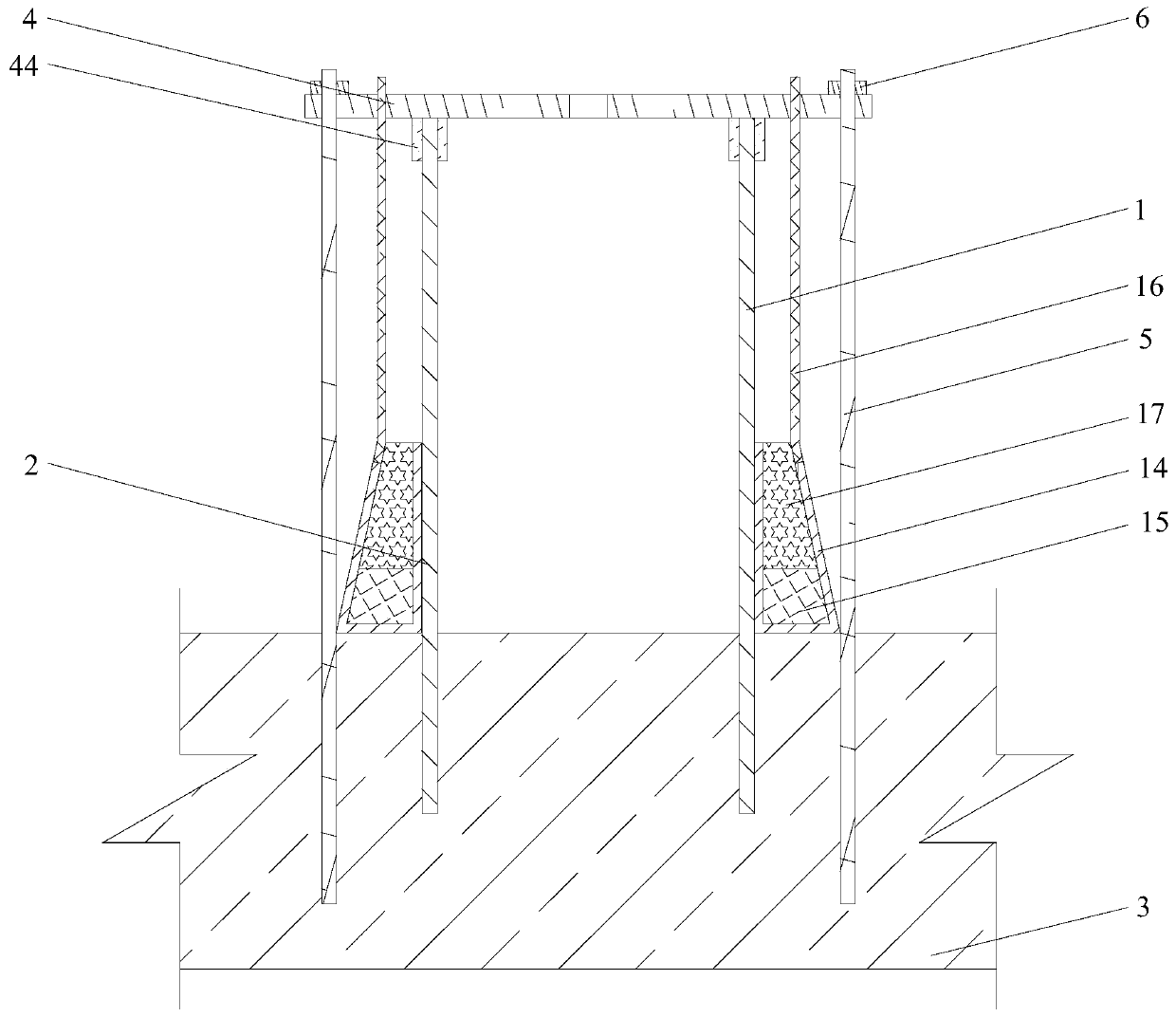

[0039] refer to figure 1 As shown, the construction method of the composite steel sheet pile cofferdam for open excavation pits in water includes the following construction steps:

[0040] 1) Construction preparation: Prepare the inner steel sheet pile 1 and the outer steel sheet pile 2, remove the soft soil in the cofferdam construction area, determine the construction process and concrete mix ratio on site, and prepare the materials and devices required for co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap