Drilling multiple-segment plugging, fracturing, grouting and water injection integrated equipment, and using method thereof

A cracking and equipment technology, applied in the field of mining equipment, can solve problems such as cracking and plugging, and achieve the effect of simple and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

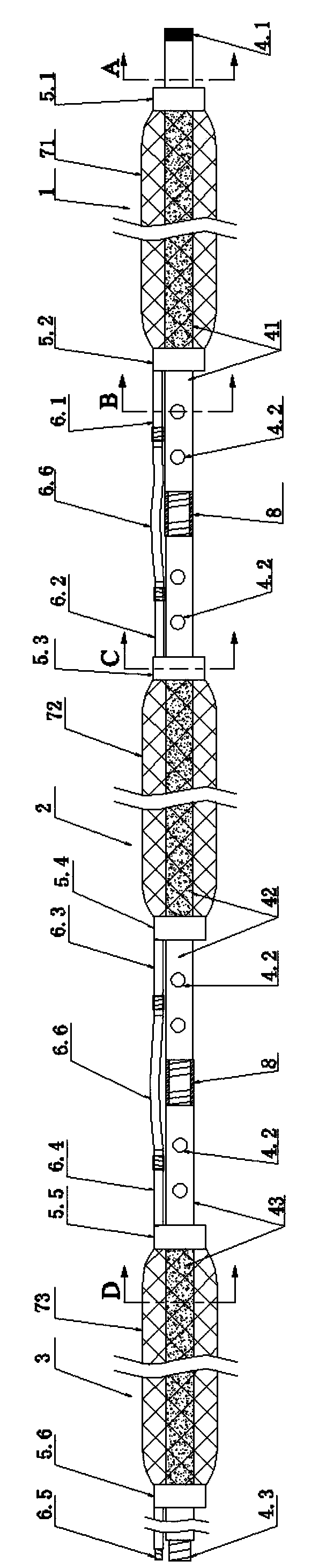

[0044] Such as Figures 1 to 7 As shown, the drilling multi-stage plugging, fracturing, grouting, and water injection integrated equipment includes a pre-sealing device 1 and several transitional sealing devices 2 connected to the pre-sealing device 1 through connectors 8, And the rear sealer 3 connected with the last transitional sealer 2 through the connector 8. When the borehole diameter is relatively short, the transitional hole sealer 2 in the middle may not be used, and the quantity of the transitional hole sealer 2 may be selected according to the actual situation for a longer borehole.

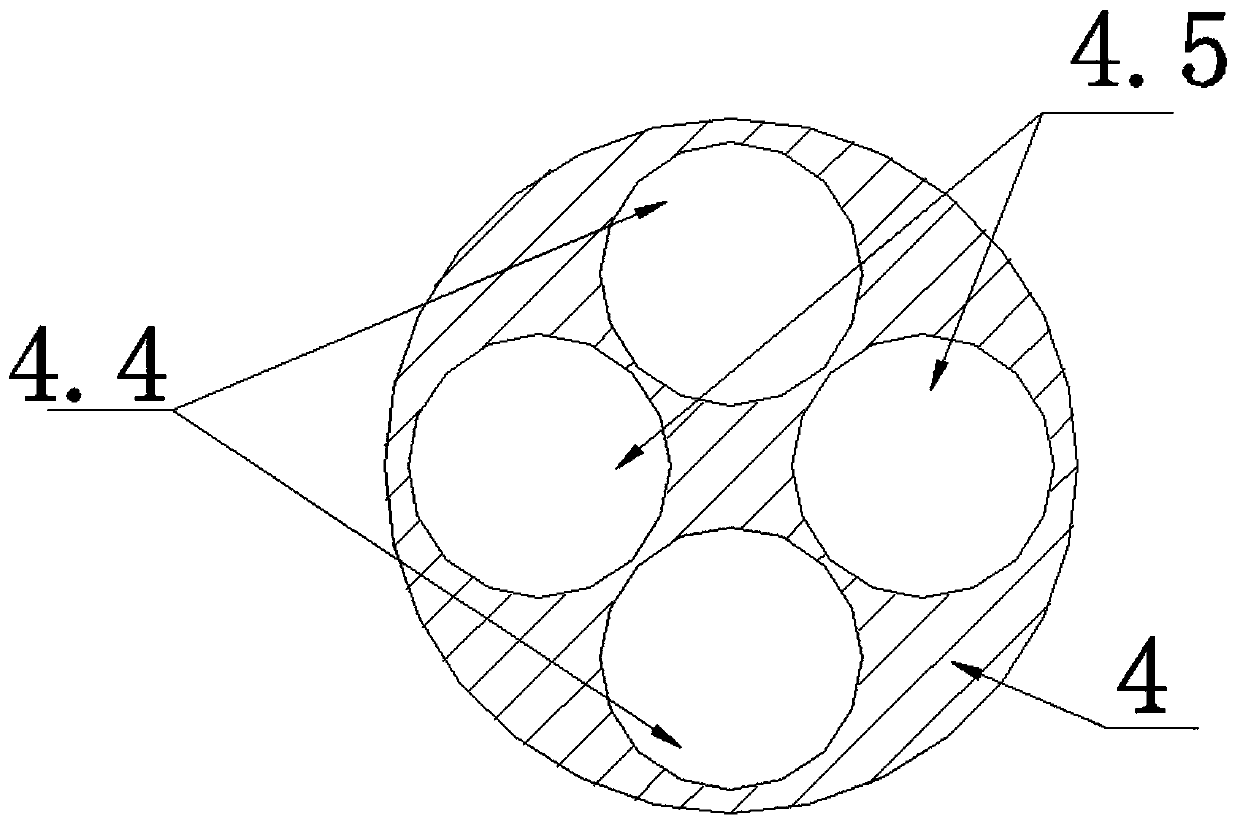

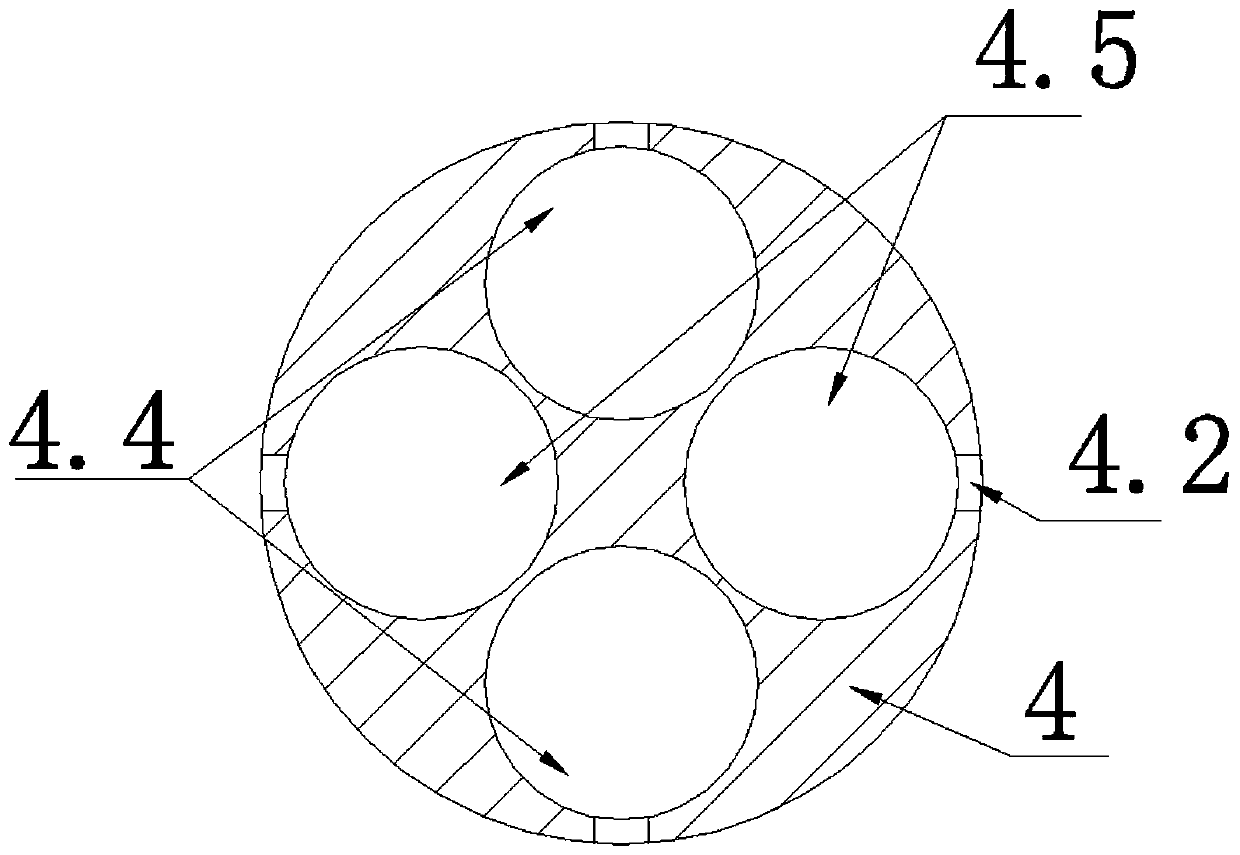

[0045] The pre-sealing device 1 includes: a pre-pumping pipe 41; a water plug 4.1 is sealed at one end of the pre-pumping pipe 41; The two ends of the expansion capsule 71 are sealed and connected to the front pumping pipe 41 through the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com