Self-assembly diffusion barrier layer copper inter-connection material and preparing method thereof

A technology of barrier layer and self-assembly, applied in metal material coating process, coating, ion implantation plating, etc., can solve problems such as circuit damage and interconnection material failure, and achieve less sample impurities, low high temperature stability, Eliminates the effect of increasing the size of copper interconnect structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

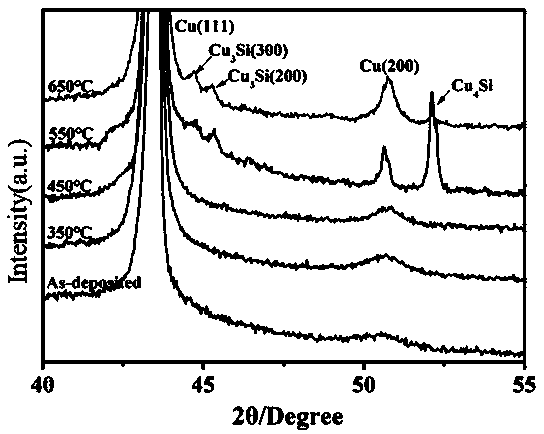

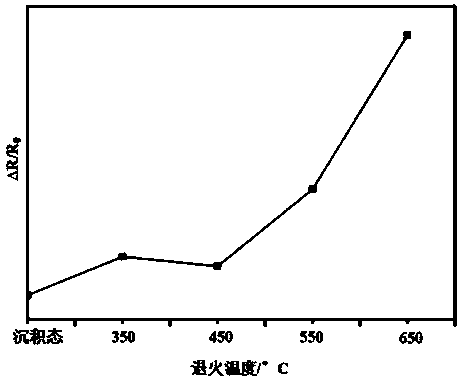

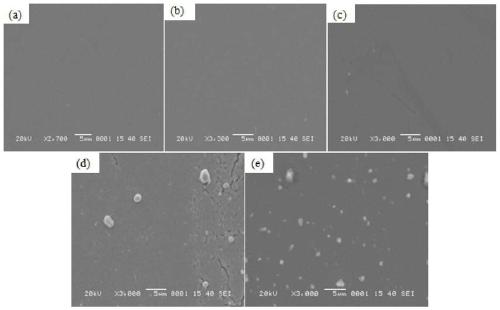

Examples

Embodiment 1

[0022] A method for preparing a self-assembled diffusion barrier layer copper interconnection material, comprising the following steps:

[0023] (1) Will 3*3*1mm 3 The W sheet is pasted on the copper target through conductive adhesive, the conductive adhesive is completely covered by the W sheet, and the position of the W sheet is 1mm away from the center of the copper target;

[0024] (2) Use acetone, alcohol and deionized water to ultrasonically clean the (100) oriented single crystal silicon wafer for 10 minutes, then take out the silicon wafer and dry it with nitrogen;

[0025] (3) Put the copper target with the W sheet and the cleaned silicon chip into the vacuum chamber, the copper target with the W sheet on the bottom, the cleaned silicon chip on the top, and sputter coating upward;

[0026] (4) Close the vacuum chamber door, and use a mechanical pump to evacuate the chamber until the air pressure is lower than 5Pa;

[0027] (5) Turn off the mechanical pump and turn o...

Embodiment 2

[0032] A method for preparing a self-assembled diffusion barrier layer copper interconnection material, comprising the following steps:

[0033] (1) Will 5*5*2mm 3 The W sheet is pasted on the copper target through conductive adhesive, the conductive adhesive is completely covered by the W sheet, and the position where the W sheet is pasted is 20mm from the center of the copper target;

[0034] (2) Use acetone, alcohol and deionized water to ultrasonically clean the (100)-oriented monocrystalline silicon wafers for 15 minutes, respectively, for 3 times, and then take out the silicon wafers and dry them with nitrogen;

[0035] (3) Put the copper target with the W sheet and the cleaned silicon chip into the vacuum chamber, the copper target with the W sheet on the bottom, the cleaned silicon chip on the top, and sputter coating upward;

[0036] (4) Close the vacuum chamber door, and use a mechanical pump to evacuate the chamber until the air pressure is lower than 5Pa;

[0037...

Embodiment 3

[0042] A method for preparing a self-assembled diffusion barrier layer copper interconnection material, comprising the following steps:

[0043] (1) Will 4*4*1.5mm 3 The W sheet is pasted on the copper target through the conductive adhesive, the conductive adhesive is completely covered by the W sheet, and the position of the W sheet is 10mm away from the center of the copper target;

[0044] (2) Use acetone, alcohol and deionized water to ultrasonically clean the (100)-oriented single crystal silicon wafer for 13 minutes respectively, and the number of times of cleaning is 2 times, and then take out the silicon wafer and blow it dry with nitrogen;

[0045] (3) Put the copper target with the W sheet and the cleaned silicon chip into the vacuum chamber, the copper target with the W sheet on the bottom, the cleaned silicon chip on the top, and sputter coating upward;

[0046] (4) Close the vacuum chamber door, and use a mechanical pump to evacuate the chamber until the air pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com