Online detection device for abrasion loss of radial sliding bearing based on pressure detection

A technology of radial sliding and bearing wear, applied in the field of detection, can solve the problem of not being able to obtain the wear amount of radial sliding bearings, and achieve the effect of eliminating external interference, improving measurement accuracy and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

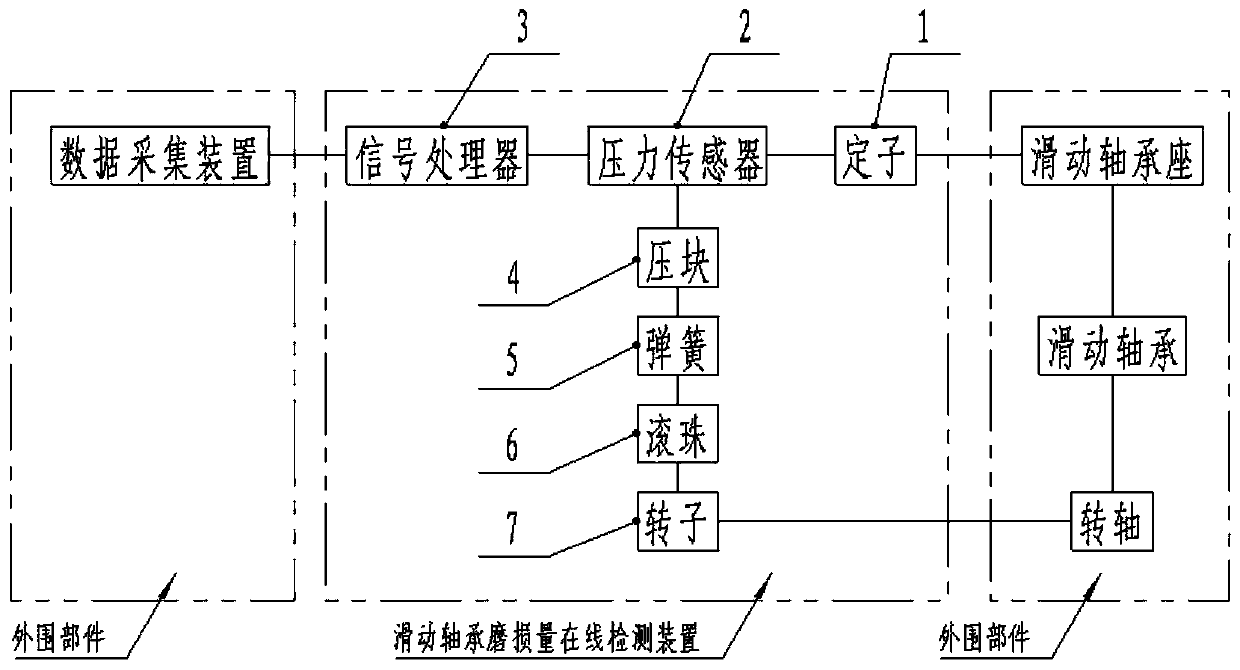

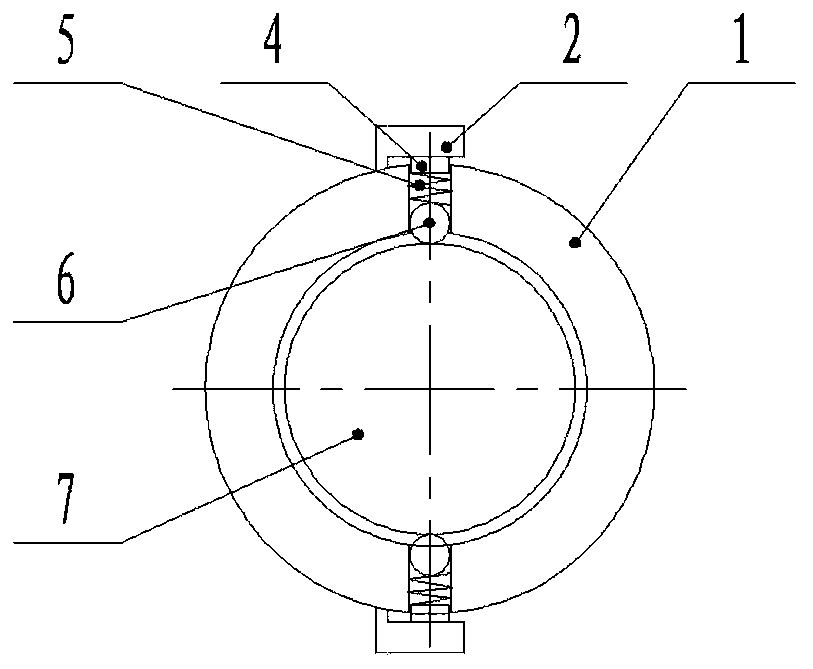

[0016] Such as figure 1 , 2 As shown, an online detection device for radial sliding bearing wear based on pressure detection includes a stator 1, a rotor 7, a pressure sensor 2, a pressure block 4, a spring 5, a ball 6 and a signal processor 3, and the stator 1 It is coaxially connected with the sliding bearing seat, the rotor 7 is coaxially connected with the rotating shaft, the stator 1 is provided with radial through holes, and the radial through holes are two and arranged symmetrically on the circumference; the pressure sensor 2. There are two pressing blocks 4, springs 5 and balls 6; the pressure sensor 2 is fixedly arranged at the outer port of the radial through hole, and the ball 6 is placed in the radial through hole and In contact with the rotor 7, the pressure block 4 is placed under the pressure sensor 2, and the spring 5 is placed between the pressure block 4 and the ball 6 to ensure that the ball 6 is in close contact with the rotor 7 and ensures that The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com