Photoelectric detection method of powder spreading amount for rapid prototyping

A detection method and photoelectric technology, applied in the direction of weighing equipment, weighing and measuring devices of materials with special properties/forms, can solve the problems of incomplete powder spreading, difficult accurate measurement, and scrapping in the powder spreading area. The effect of improving forming accuracy and quality, simple method steps and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

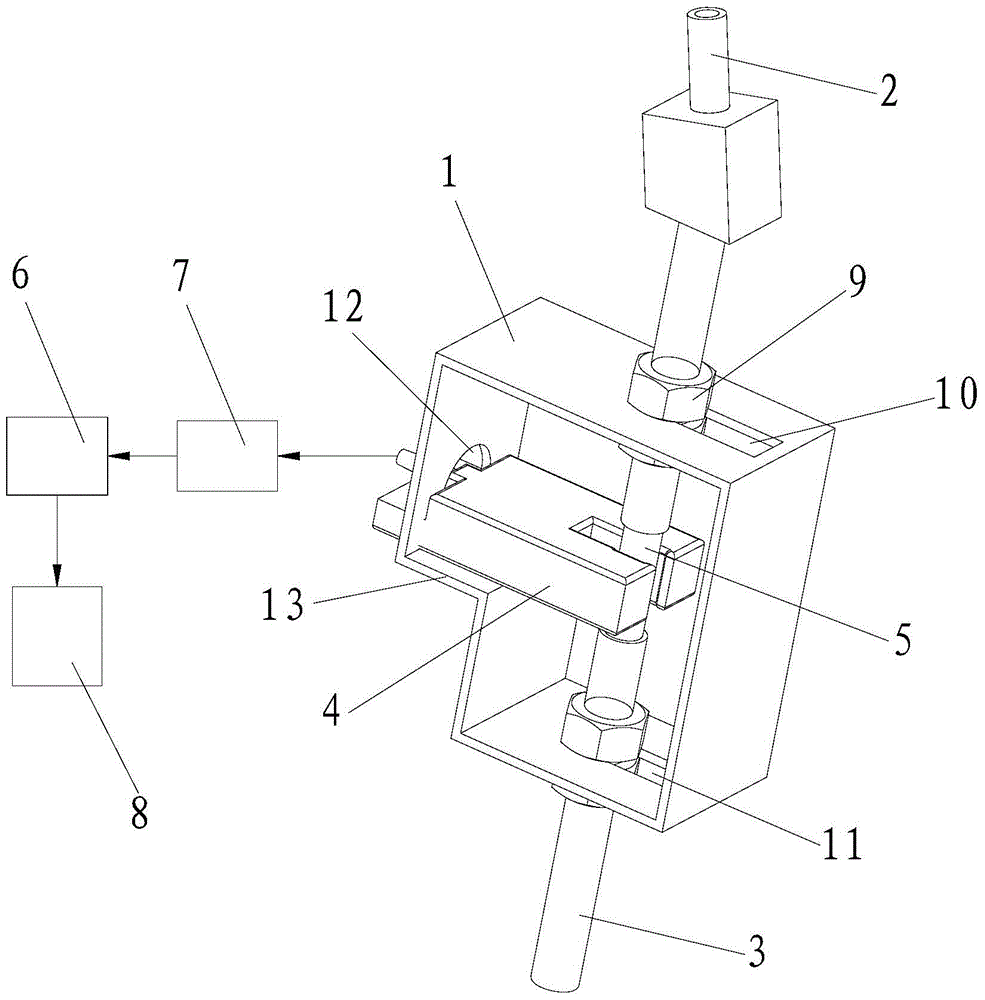

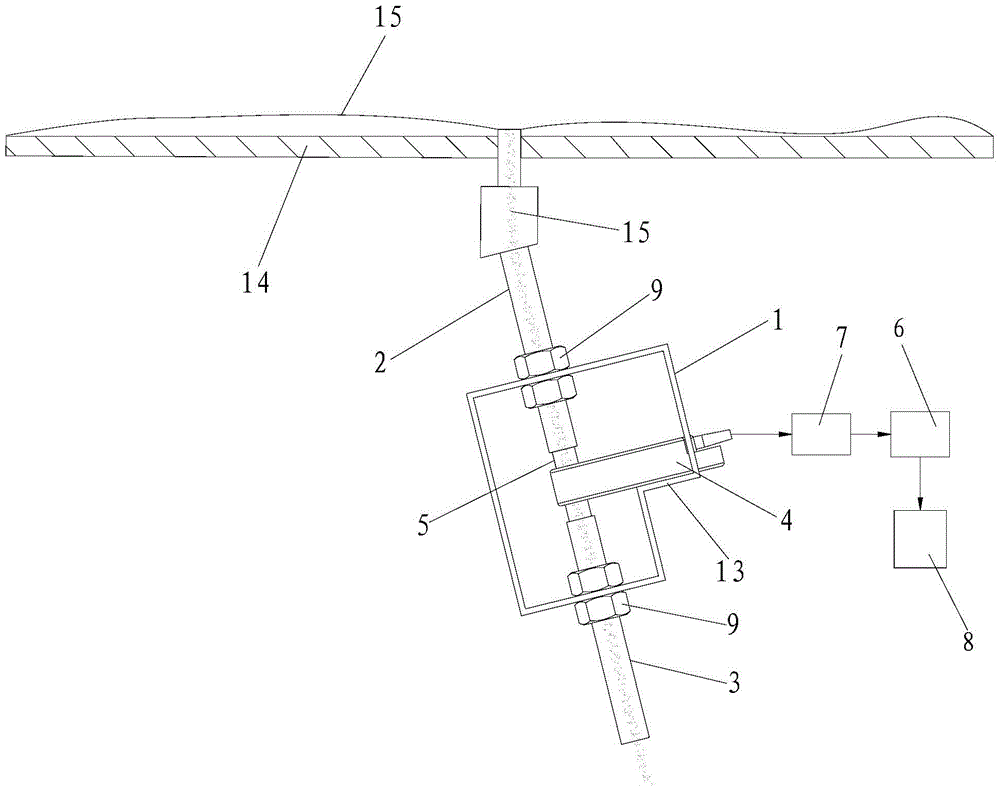

[0040] like figure 1 As shown, the rapid prototyping powder spreading amount photoelectric detection system of the present invention includes a powder flow detection mechanism, a controller 6 and a computer 8 connected to the controller 6, and the powder flow detection mechanism includes a fixed bracket 1 and a fixed connection On the fixed support 1, the upper and lower powder tube 2, the lower powder tube 3 and the photoelectric sensor 4, the light-transmitting tube 5 is connected between the upper and lower powder tube 2 and the lower powder tube 3, and the emission of the photoelectric sensor 4 The end and the receiving end are respectively located on both sides of the transparent tube 5, the input end of the controller 6 is connected with a timer 7, and the signal output end of the photoelectric sensor 4 is connected with the signal input end of the timer 7.

[0041] like figure 1 As shown, in this embodiment, the upper and lower powder pipes 2 and 3 are vertically and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com