Pollution source coagulable particulate matter sampling device and method

A sampling device and particle technology, applied in the field of testing, can solve the problems of different graded particles, the same cutting point, accurate measurement of condensable particles, etc., and achieve the effect of reducing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the drawings.

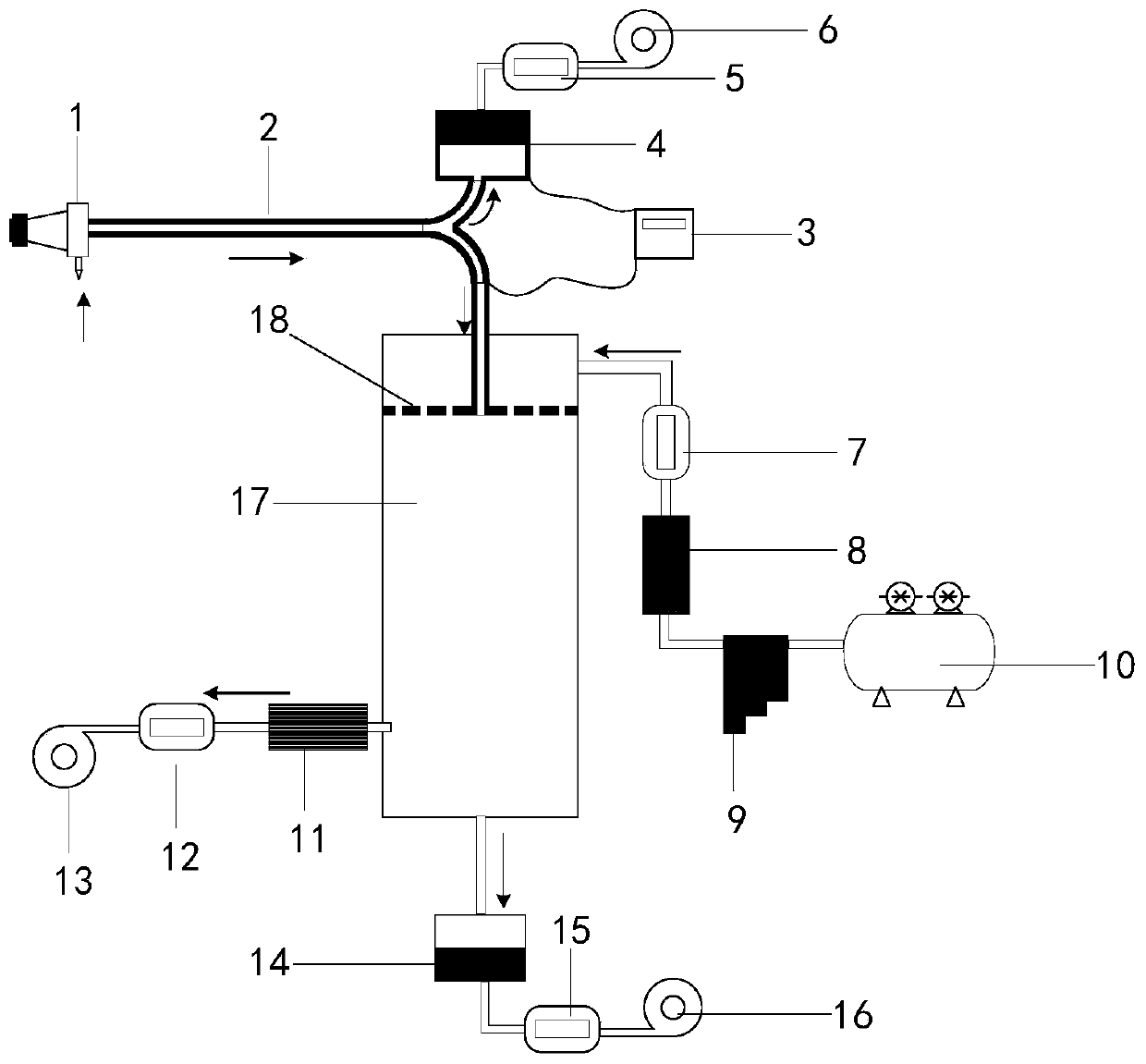

[0031] Such as figure 1 The illustrated embodiment of the present invention includes: particulate classification device 1, flue gas pipeline 2, heating and heat preservation device 3, filterable particulate matter collection device 4, filterable particulate matter flow meter 5, filterable particulate matter extraction device 6, dilution air Flow meter 7, dilution air particulate filter device 8, dilution air organic matter and water vapor removal device 9, dilution air supply device 10, bypass air particulate filter device 11, bypass air flow meter 12, bypass air extraction device 13, The total particulate matter collection device 14, the total particulate matter flow meter 15, the total particulate matter extraction device 16, the dilution chamber 17 and the air distribution plate 18; wherein the particulate matter classification device 1 is connected to the air distribution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com