Method for manufacturing optical cable

A manufacturing method and technology of optical cables, applied in transportation and packaging, fiber mechanical structure, loading/unloading, etc., can solve problems such as easy blockage of pipelines, material supply failure, heavy workload, etc., to ensure stable work and reduce workload , The effect of reducing the frequency of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

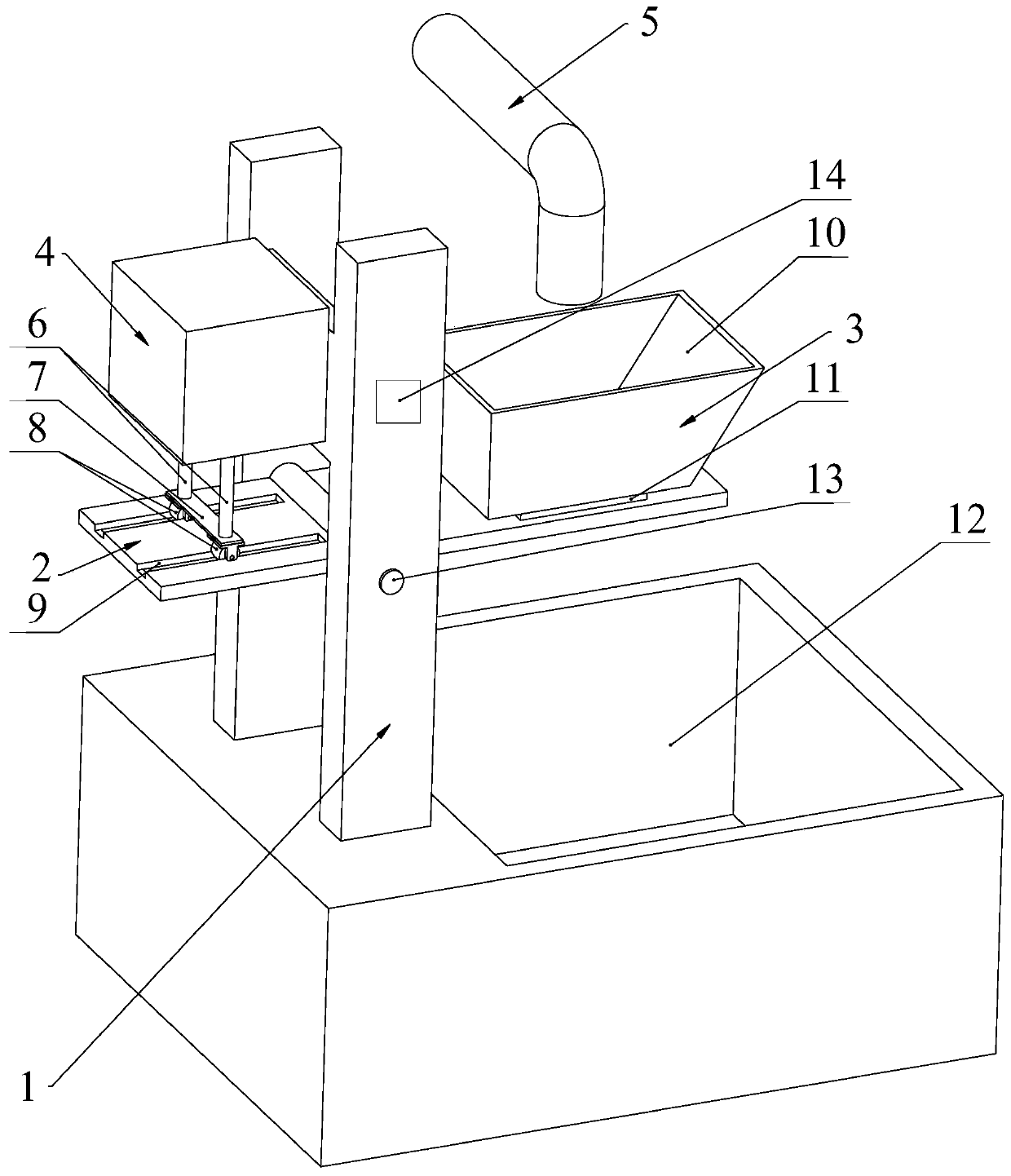

[0040] Below in conjunction with each accompanying drawing, the present invention is described in detail.

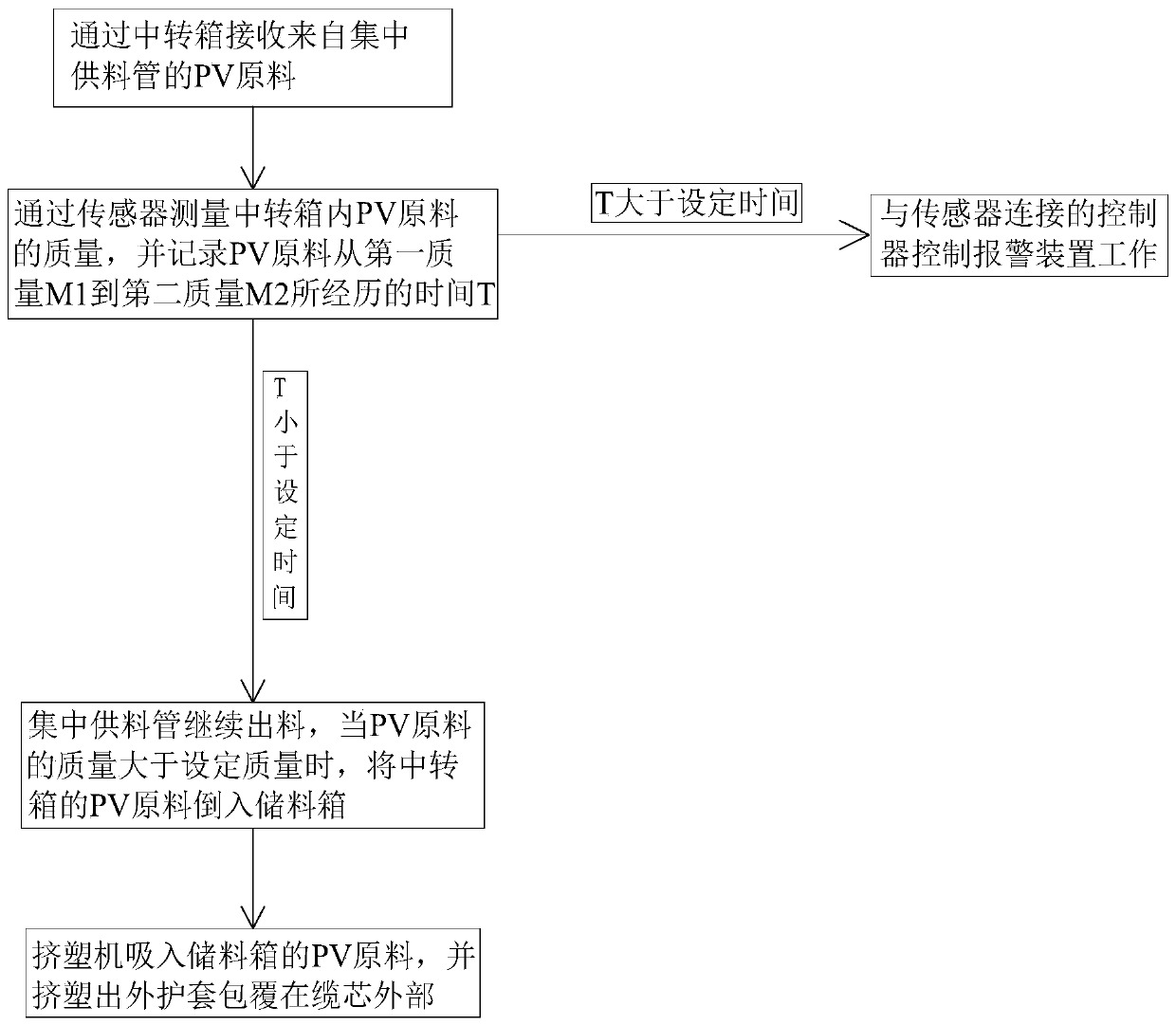

[0041] Such as figure 1 Shown, a kind of manufacturing method of optical cable, comprises the following steps:

[0042] 1) Receive the granular sheath raw material from the centralized feeding pipe through the transfer box;

[0043] 2) Measure the quality of the sheath material in the transfer box through the sensor, and record the time T that the sheath material passes from the first mass M1 to the second mass M2. When the time T is greater than the set time, the controller connected to the sensor Control the work of the alarm device;

[0044] 3) The centralized feeding pipe continues to discharge materials. When the quality of the sheath raw material is greater than the set quality, pour the sheath raw material in the transfer box into the storage box;

[0045] 4) The extruder sucks the sheath raw material from the storage box, and extrudes the outer sheath to cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com