Semi-permanent dam foundation structure of rubber dam for river regulation

A semi-permanent, rubber dam technology, applied in infrastructure engineering, sea area engineering, construction, etc., can solve problems such as reduction, achieve the effects of reducing dredging frequency, beautifying the environment, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

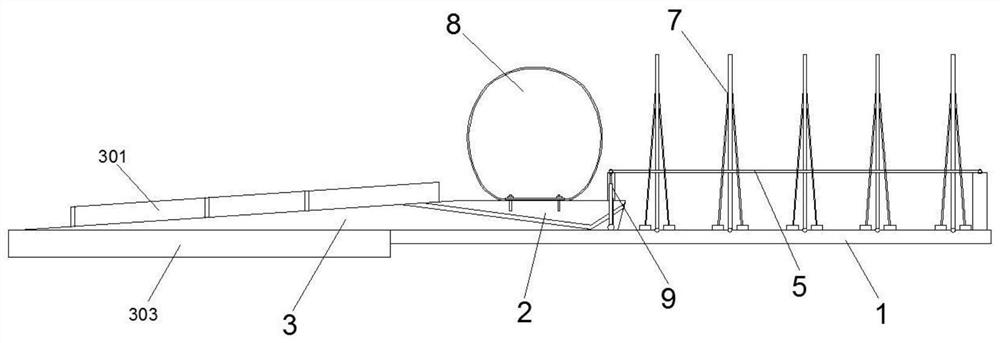

[0037] like figure 1 and 2 As shown, a semi-permanent dam foundation structure of a rubber dam for river management includes a raised base 2 that carries a rubber dam 8 in the river, that is, the rubber dam 8 is fixedly installed on the raised base 2, and the raised base 2 cuts off the river, so The upstream of the raised base 2 is provided with an anti-silting area 1, and the downstream is provided with a settlement drainage area 3. The raised base 2, the anti-silting area 1 and the settlement and drainage area 3 are all built with cement concrete on the river bed. The height of the anti-silting area 1 is The lowest, generally 2-5cm thick cement concrete layer is sufficient. The raised base 2 protrudes from the anti-siltation zone 1, and its height depends on the water flow of the river. The upstream of the drainage area 3 is connected with the lifting base 2, and the downstream is gradually lowered. There are several lever assemblies 7 distributed on the anti-siltation area...

Embodiment 2

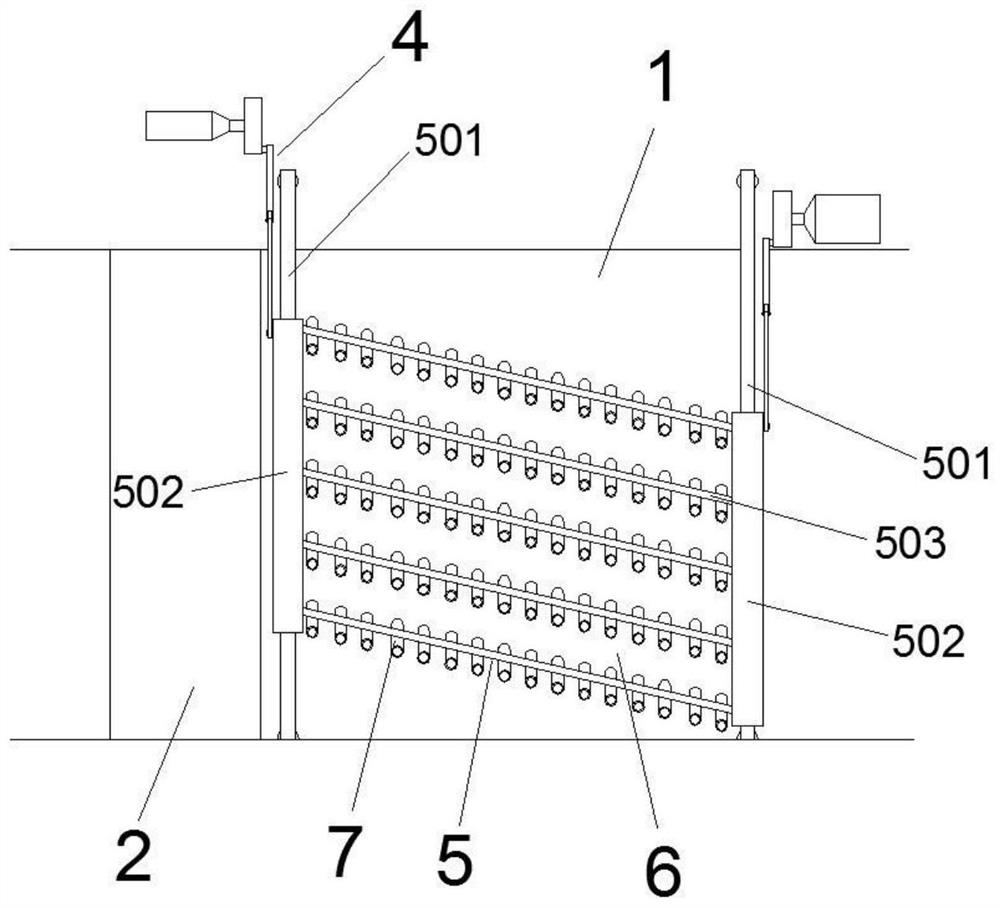

[0043] This embodiment is an improvement scheme made on the basis of Embodiment 1, and its main structure is the same as that of Embodiment 1. The improvement points are as follows: image 3 , 4 As shown in and 5, the reciprocating toggle mechanism 5 includes two horizontal support rods 501 spanning the width direction of the river. The horizontal support rods 501 are generally stainless steel pipes, and are located below the water surface after the rubber dam 8 is installed and stored, and in the middle. and both ends are supported by stainless steel pipes 504, the length of which is determined by the width of the river. One of the two horizontal support rods 501 is located on the water-facing side of the rubber dam 8, and the other is located further upstream. Two horizontal support rods An anti-siltation zone 1 is formed between 501, and each horizontal support rod 501 is provided with two sleeves 502 slid symmetrically along the center of the river. , so as to ensure that...

Embodiment 3

[0045] This embodiment is an optimization scheme made on the basis of Embodiment 2, and its main structure is the same as that of Embodiment 2. The optimization point is that the two casings 502 located on the same side of the river move in the same direction and move in the same direction. Movement means that when the two sleeves 502 are driven to and fro by the two crank-slider mechanisms 4 respectively, the movement directions are always consistent, that is, they move to the side close to the river bank or to the side close to the center of the river at the same time. move, and its moving speed and stroke are consistent, and the upstream one of the two sleeves 502 is closer to the center of the river than the initial position downstream; two sleeves located on the same horizontal support rod 501 The pipe 502 moves in an opposite direction. The anisotropic movement means that the two sleeves 502 on the same horizontal support rod 501 are respectively driven by the two crank-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com