Treatment method to improve the curing quality of flooded tobacco leaves

A processing method and technology of tobacco leaves, which are applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of long time for gluten change, reduction of tobacco farmers' enthusiasm for planting tobacco due to disasters, and improper grasp of harvesting timing and method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

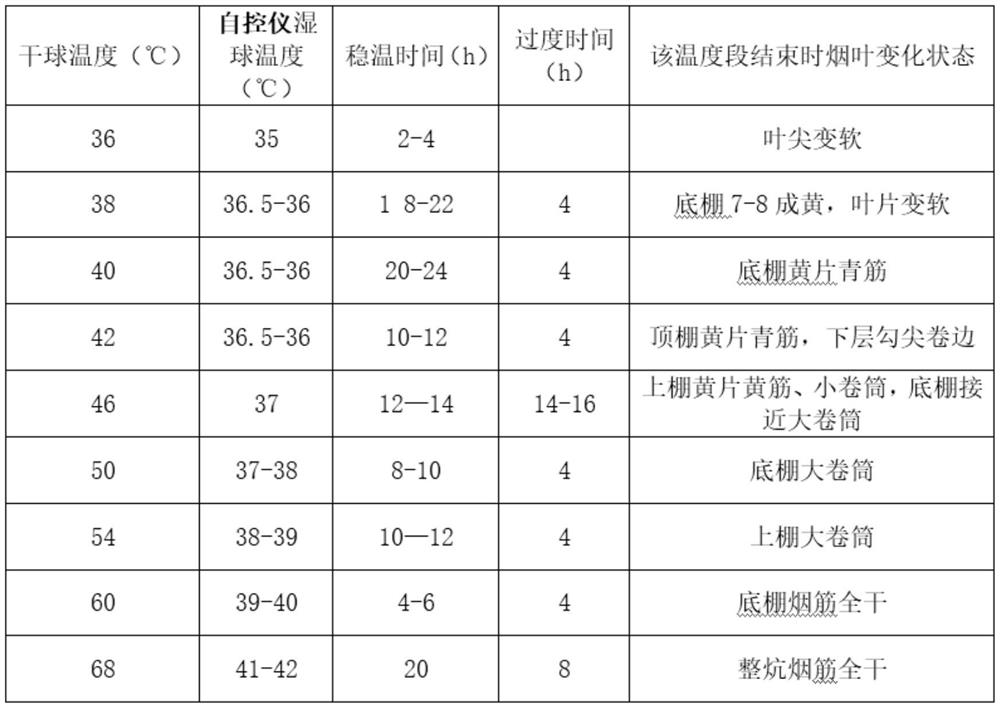

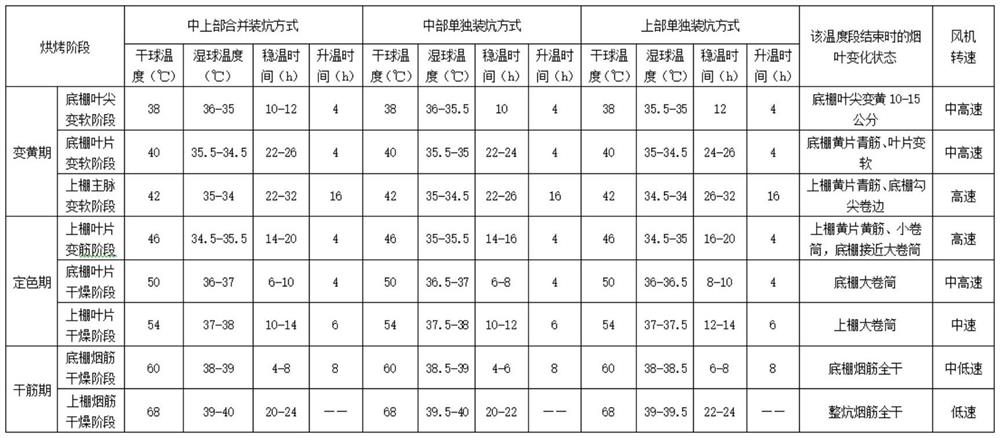

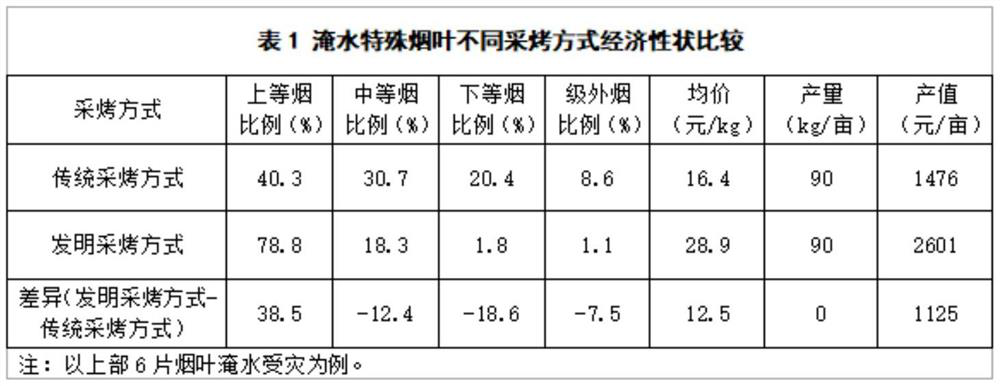

[0059] Aiming at the quality characteristics of tobacco leaves such as insufficient accumulation of dry matter, insufficient maturity, and poor roasting resistance of special waterlogged tobacco leaves, the present invention adopts the method of "sorting and rushing to collect before dehydration and withering, and sorting tobacco according to parts to pack the kang, turning yellow at high temperature and low humidity". The method of collecting and roasting special flooded tobacco leaves at the core of "fixing color", that is, for the tobacco leaves that have been flooded for more than 24 hours, the middle and upper parts of the tobacco leaves are rushed to be harvested before the leaves wither, and the middle and upper parts are divided into smoke and kang to turn the main leaves into yellow. The temperature is increased from 38-40°C to 40-42°C, which reduces the yellowing period and the wet bulb temperature in the early stage of color fixing by 1-3°C compared with the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com