high performance gynecological forceps

A high-performance, gynecological technology, applied in the field of medical devices, can solve the problems of poor control of the gripping force of the fetal head, easy injury to the fetus and the mother, and achieve the effects of simple structure, safety and ease of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

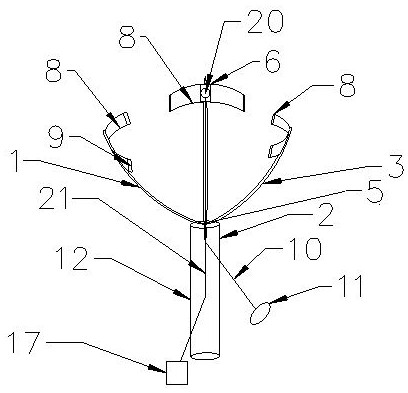

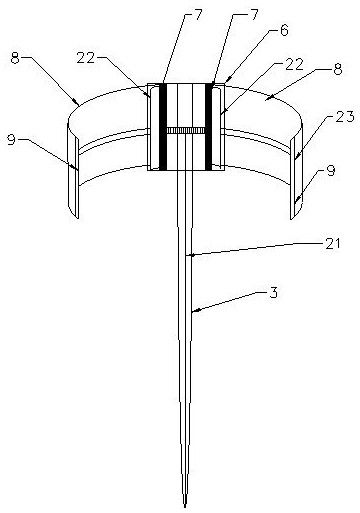

[0022] During specific implementation, a kind of high-performance gynecological forceps, such as figure 1 As shown, it includes a clamping part 1 and a tightening part 2 whose centers of gravity are on the same axis. The top edge of the tightening part 2 fits against the bottom outer wall of the clamping part 1. Three clamping rods 3 are distributed, and the clamping rods 3 are arc-shaped supports 4 bent upwards from the bottom, so that the three clamping rods 3 form a funnel shape, and the bottoms of the arc-shaped supports 4 are gathered and fixed at the joint 5 , the connection 5 is located on the central axis of the tightening part 2, the other end of the connecting part 5 is fixed with a pole 10, the other end of the pole 10 is fixed with a handle 11, the tightening part 2 The outer wall is provided with a handle 12, and a limit stop is provided between the joint 5 and the pole 10 to ensure that the joint 5 is always located on the central axis of the tightening part 2 wh...

Embodiment 2

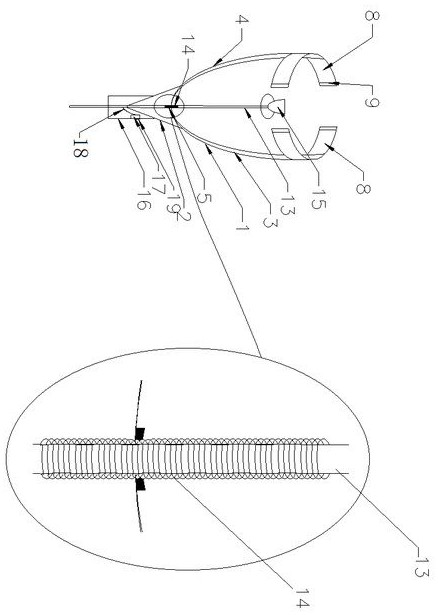

[0027] In another embodiment, a high-performance gynecological forceps, such as image 3 As shown, the difference from Example 1 is that the tightening part 2 is provided with two symmetrical clamping rods 3, the tightening part 2 is an inverted triangular pyramid, and the top of the tightening part 2 The edge fits against the outer wall of the bottom of the clamping part 1. The lower end of the tightening part 2 is connected with a handle part 16, and its bottom cone is embedded in the inside of the handle part 16. The clamping part 1, the tightening part 2, the handle The position of the center of gravity axis of the part 16 is provided with a shrink tube 13. The shrink tube 13 is made of hard material, the inside is hollow, and has a certain tensile strength. The bottom end of the clamping part 1 passes through the shrink tube 13. It is clamped with the tightening part 2, and the connection 5 between the shrink tube 13 and the clamping part 1 is provided with a correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com