Novel dry-cleaning liquid purifier

A technology of dry cleaning liquid and purifier, which is applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of waste of dry cleaning solvent, time-consuming and laborious, expensive dry cleaning solvent, etc., and achieve the effect of improving effect and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

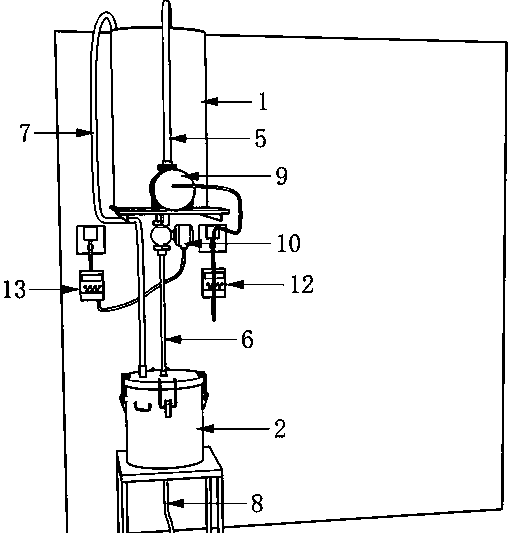

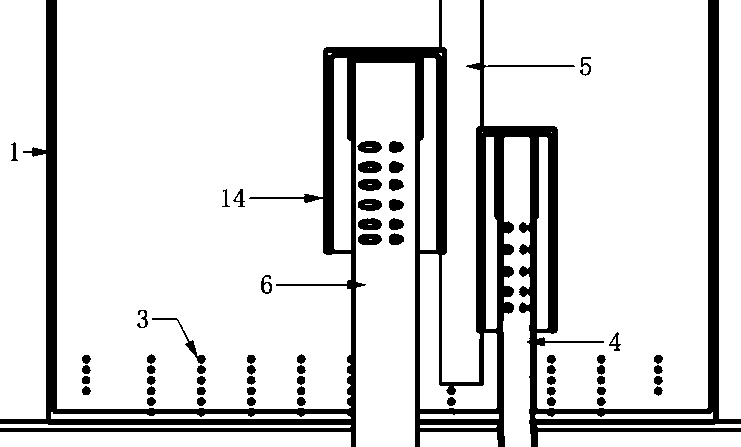

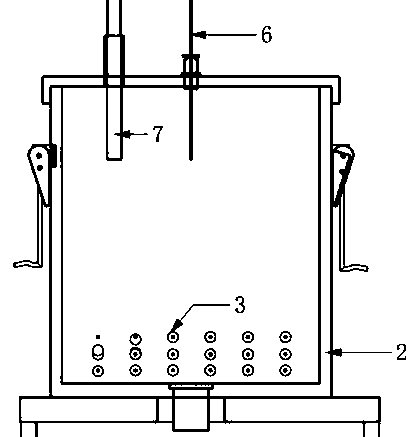

[0027] In order to better demonstrate the content of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] As shown in the figure, a new type of dry cleaning liquid purifier includes a primary filter barrel 1, a secondary filter barrel 2, activated carbon 3, a first pipeline 4, a second pipeline 5, a third pipeline 6, a fourth pipeline 7, and a fifth pipeline. Pipeline 8, water pump 9, water control solenoid valve 10, filter screen 11, first timer 12, second timer 13, dirty and clean separator 14, valve 15; the primary filter barrel 1 is the purification container of the first process, And it is fixed at a position higher than the dry cleaning machine 16; activated carbon 3 is placed at the bottom of the primary filter bucket 1, and the activated carbon 3 can play the role of adsorption and filtration; during use, it is found that the activated carbon 3 in the primary filter bucket 1 is in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com