Perpendicularity verification device used in reaming process of reamer and processing method and verification method

The technology of a calibration device and processing method is applied in the direction of thread cutting devices, metal processing equipment, metal processing machinery parts, etc., and can solve the problems such as difficult calibration of the verticality of threaded holes, so as to facilitate later use, facilitate calibration, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0039] Embodiments of the verticality verification device (hereinafter referred to as the verification device) of the reamer reaming process of the present invention:

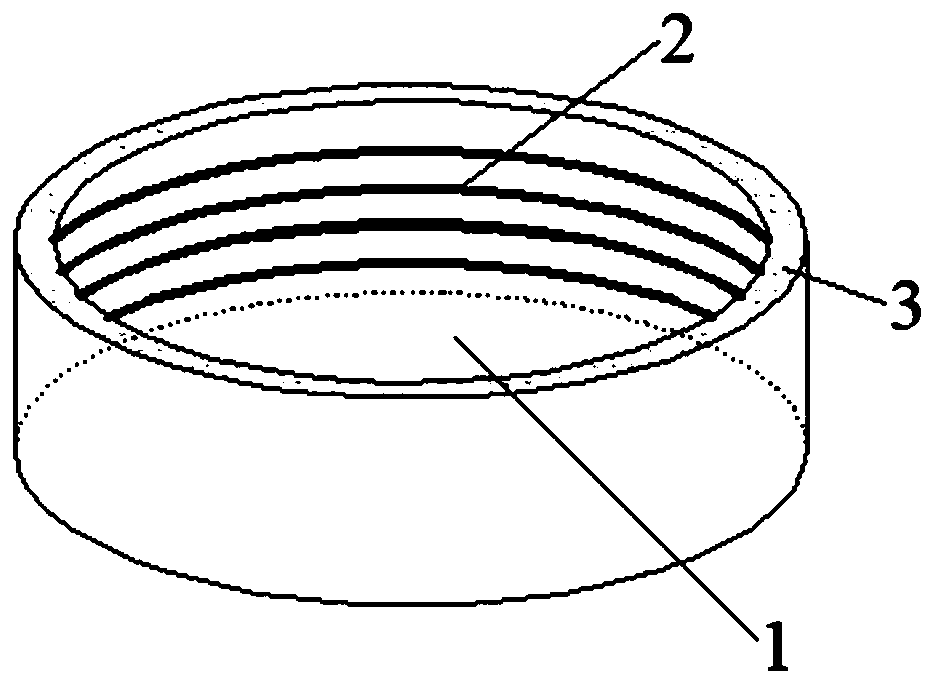

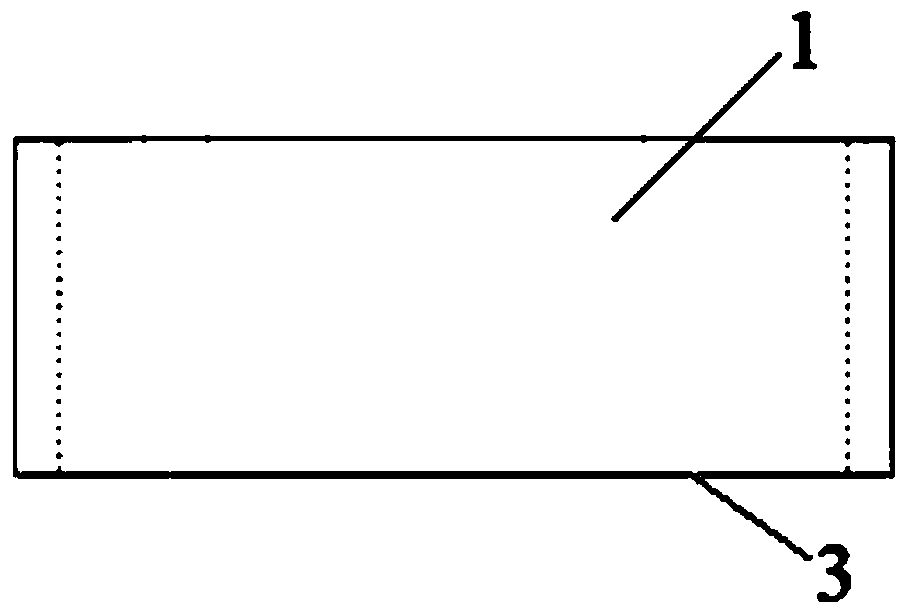

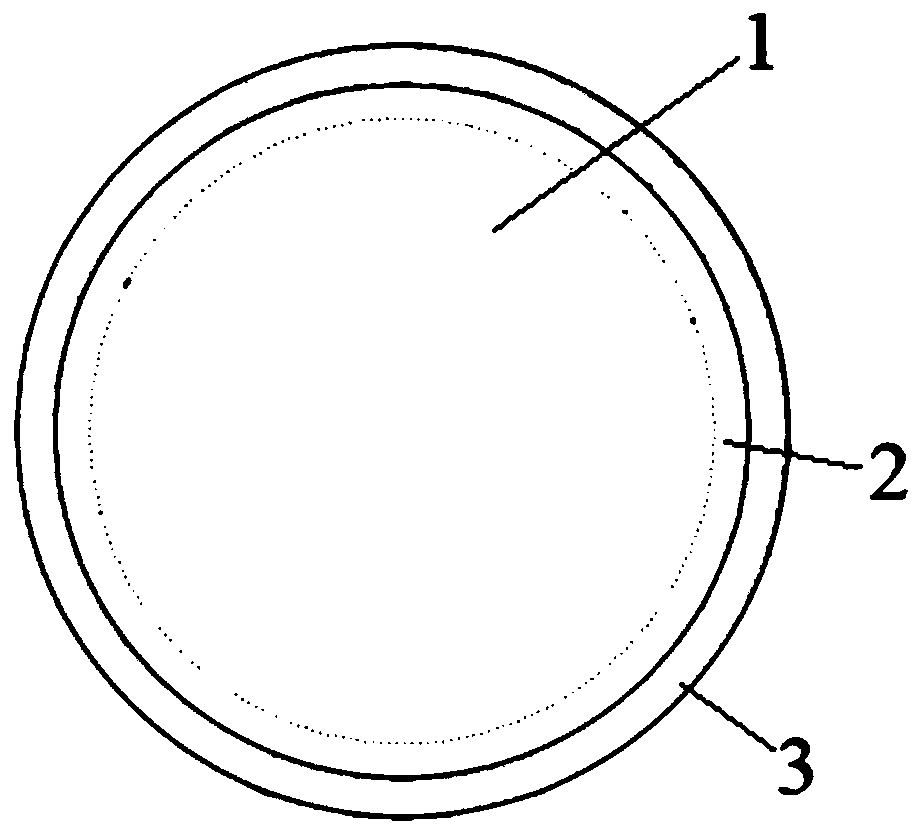

[0040] Such as Figure 1 to Figure 3 As shown, the verification device includes an annular body, and a threaded hole 1 is arranged in the annular body, and the threaded hole 1 is used for threading assembly with the external thread of the corresponding reamer 4, and at least one side port position of the threaded hole 1 is An annular datum plane 3 is provided, said annular datum plane 3 is perpendicular to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com