Full-automatic numerical control cutter grinding machine with inner hole and outer circle grinding function

A tool grinding machine and inner hole grinding technology, applied in the direction of grinding machine, grinding machine parts, workpiece feed motion control, etc., can solve problems affecting workers' physical and mental health, etc. The effect of reducing body damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

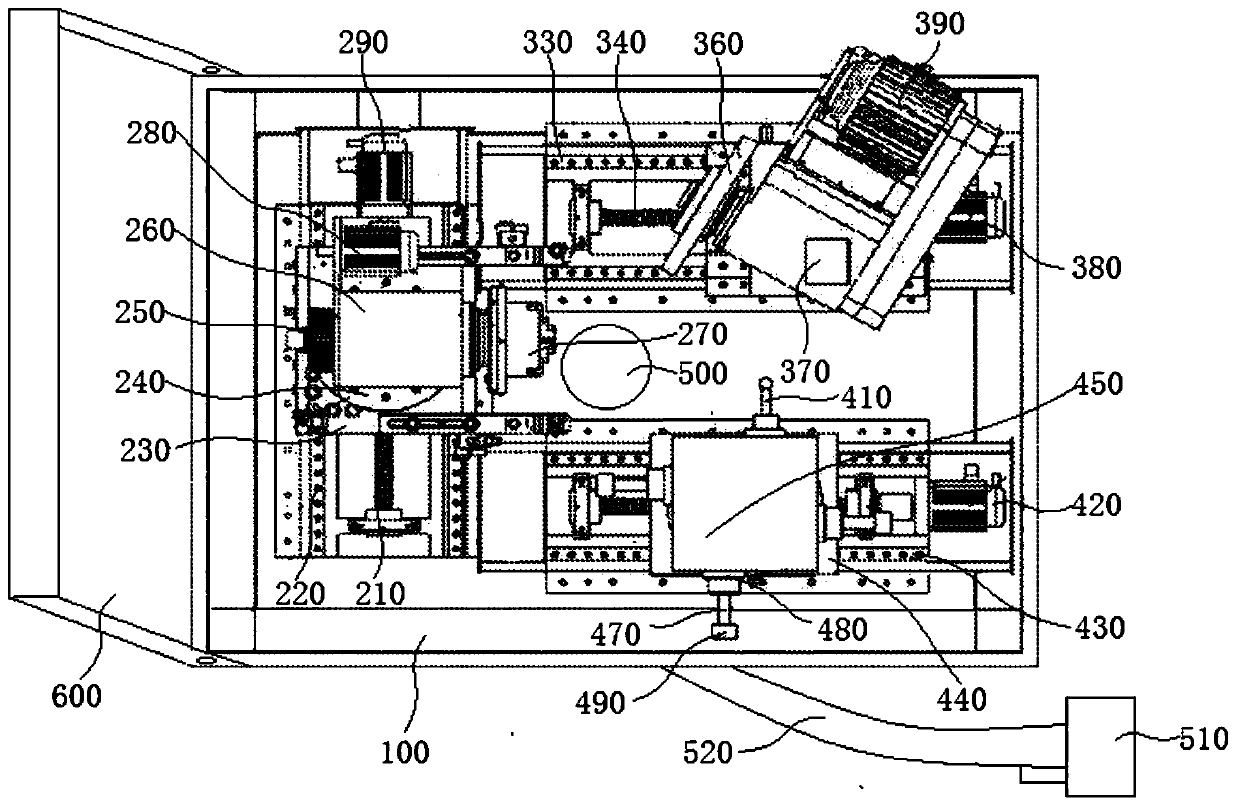

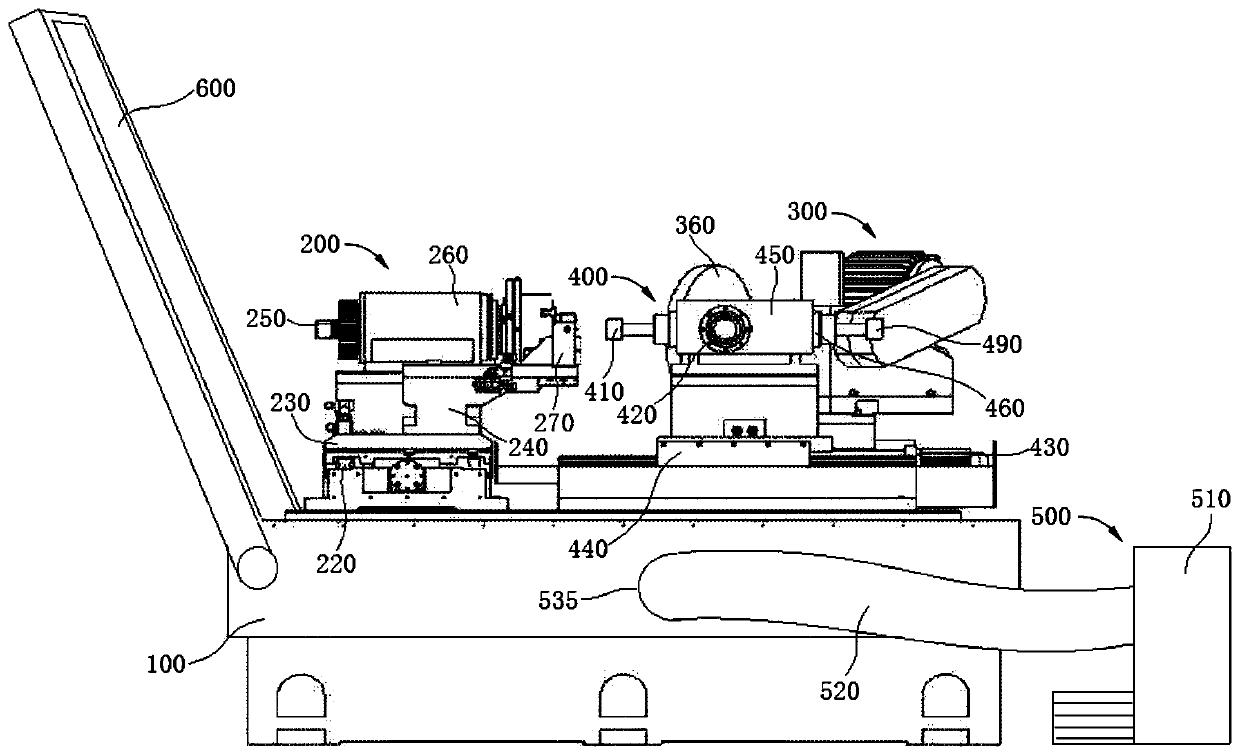

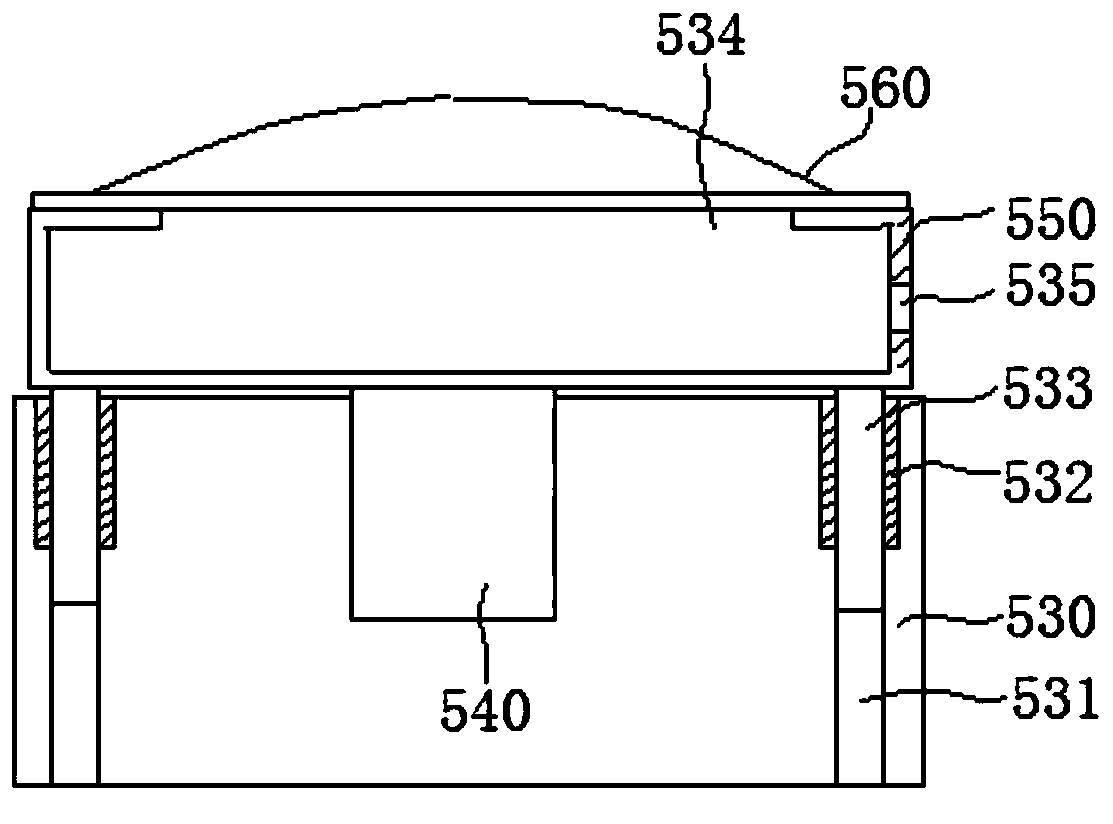

[0045] Such as Figure 1 to Figure 4 As shown, a fully automatic CNC grinding machine for inner holes and outer circle cutters includes: a frame 100, which bears the weight of the entire grinding machine; For fixing the workpiece to be processed; the cylindrical grinding unit 300, which can be relatively movable, is arranged on the frame 100, close to the workpiece to be processed, and performs cylindrical processing on the workpiece to be processed; the inner hole grinding unit 400, which can be relatively The mobile device is installed on the frame 100, and extends into the inner hole of the workpiece to be processed to process the inner hole; the adsorption unit 500, which is placed under the engaging unit 200, absorbs dust and iron filings The control unit, which is a PLC controller, can be placed in the front end or the central control room of the grinding machine frame, and is electrically connected with the engaging unit 200, the cylindrical grinding unit 300, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com