Plastic woven bag crushing equipment

A technology of plastic woven bags and crushing equipment, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of poor crushing effect and uncontrollable feeding speed, and achieve the effect of increasing crushing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

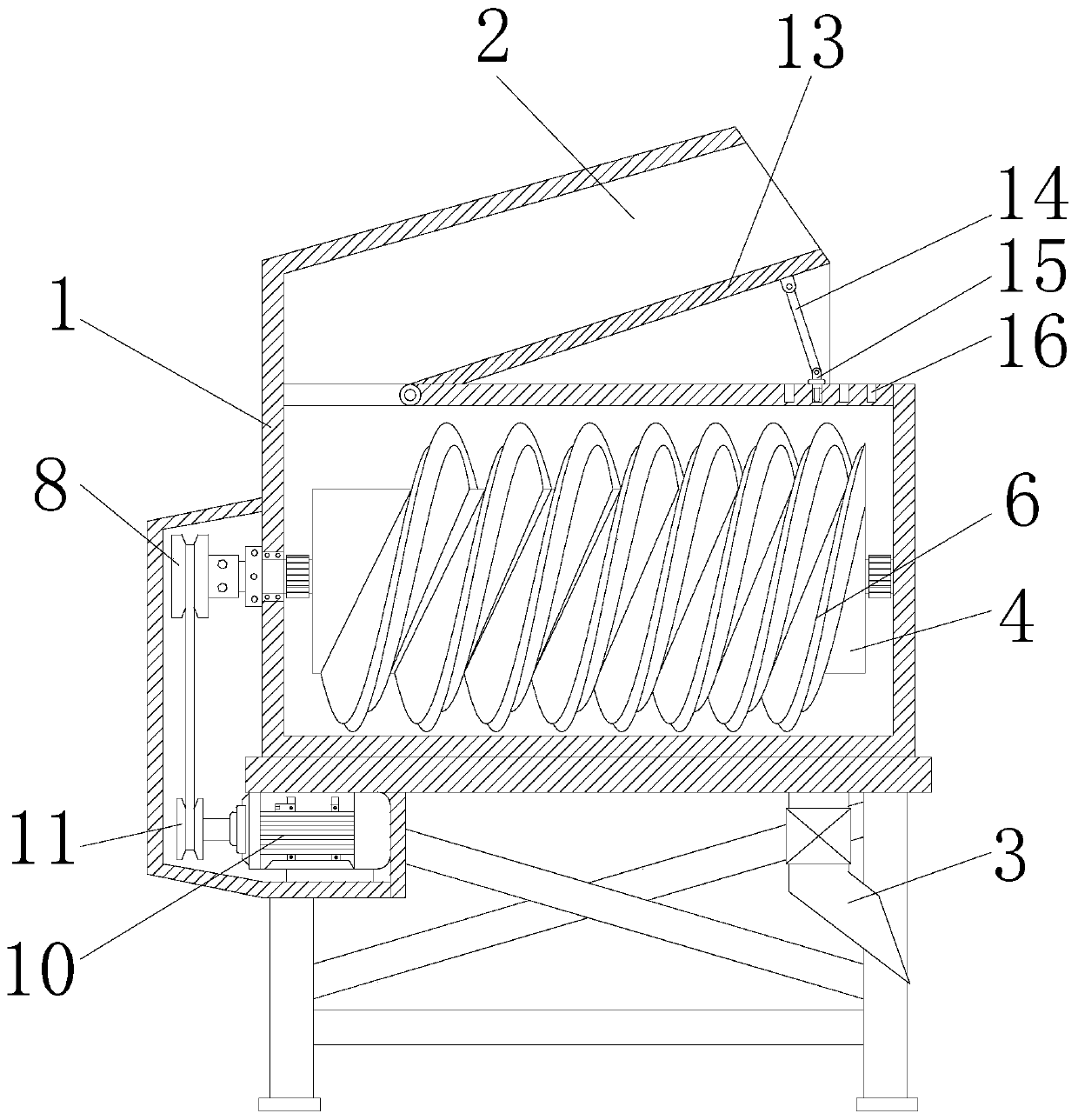

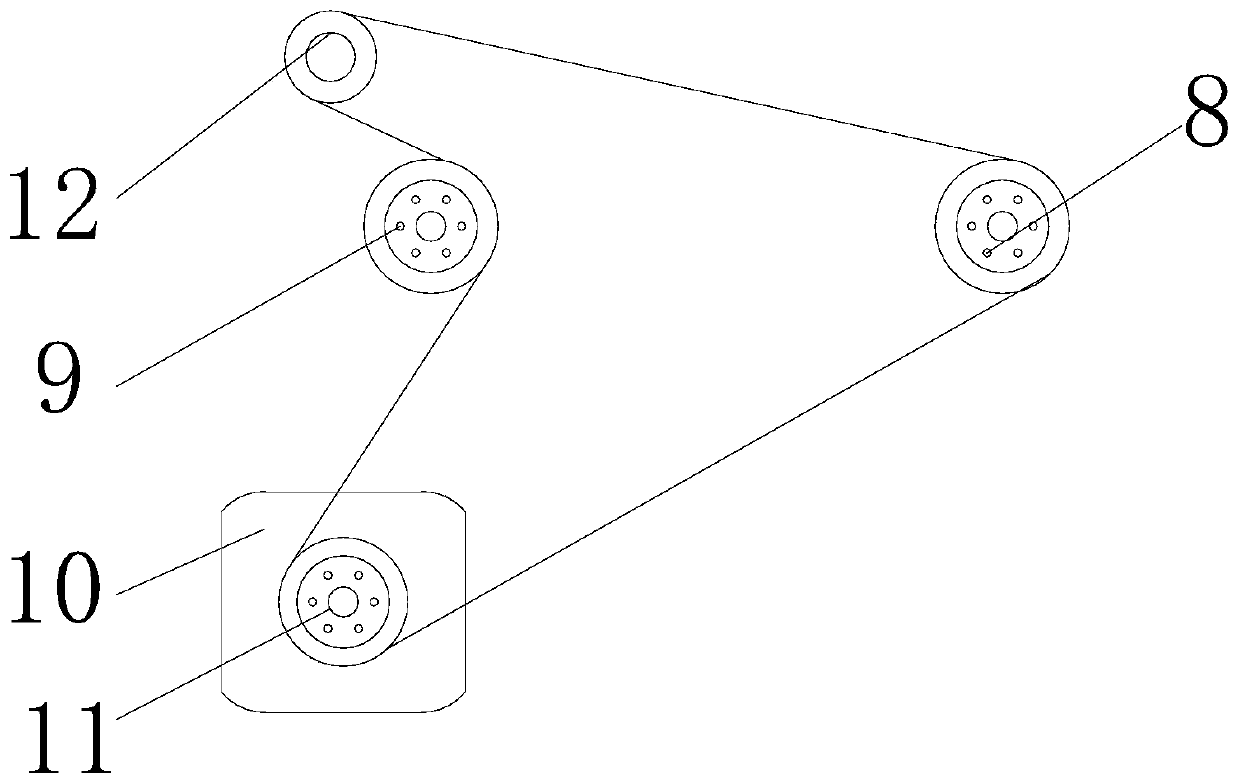

[0024] As a specific embodiment of the present invention, a pinch pulley 12 is provided on the left outer wall of the box body 1 and above the second pulley 9 .

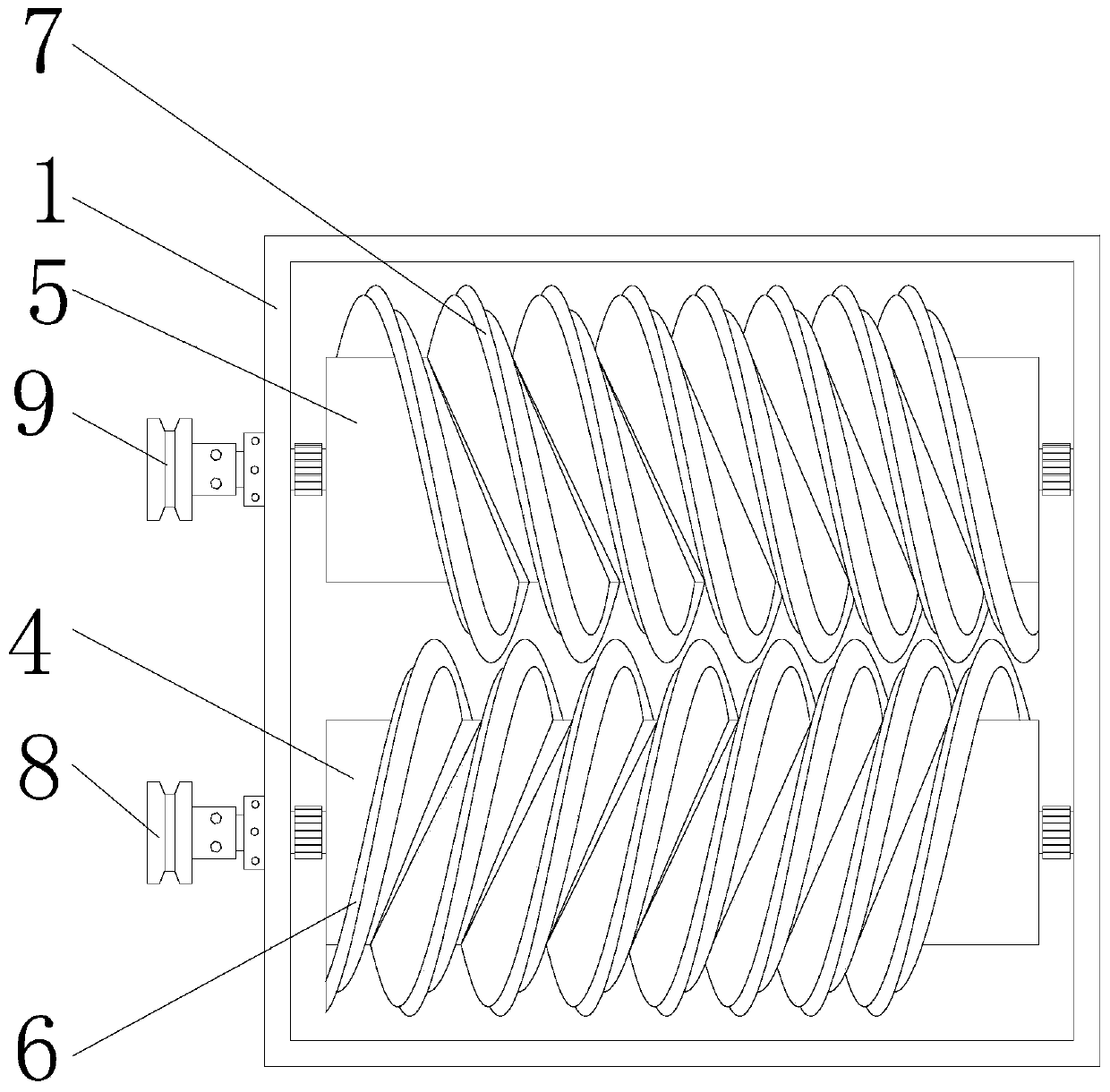

[0025] As a specific embodiment of the present invention, the first extrusion roller 4 rotates counterclockwise, the second extrusion roller 5 rotates clockwise, and the first extrusion roller 4 and the second extrusion roller 5 can be The force of mutual extrusion is formed, and the cutting by the first spiral hob 6 and the second spiral hob 7 accelerates the crushing speed of raw materials.

[0026] As a specific embodiment of the present invention, the discharge port 3 is located at the top of the box body 1, the position of the discharge port 3 is also provided with a blanking plate 13, and the blanking plate 13 is located at one end of the box body 1 and Hinged, the position between the end of the blanking plate 13 away from the box body 1 and the box body 1 is provided with a support frame 14, the support frame...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap