Water-based pearlescent medium used for water-based printing ink of decorative paper and preparation method of medium

A decorative paper and printing ink technology, which is applied in the field of ink and ink, can solve the problems of affecting the printing pearlescent effect of finished decorative paper, high viscosity of printing ink, and inability to print on the machine smoothly, so as to achieve printing clarity, good compatibility, and guarantee The effect of pearlescent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

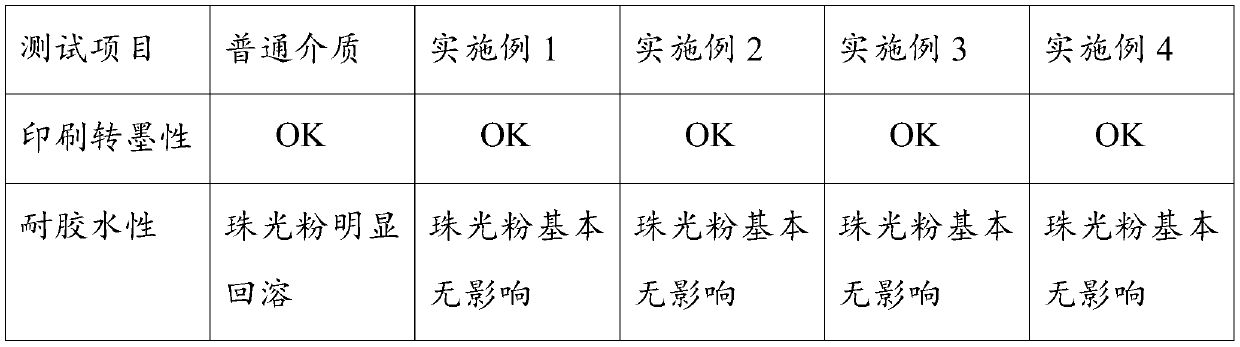

Examples

Embodiment 1

[0025] A water-based pearlescent medium used for water-based decorative paper printing ink, the raw material components are: 4% casein, 76% water, 1.7% caprolactam, 0.8% pH regulator, 14% water-based polyurethane resin, disinfectant Foam agent 1.8% and water-based preservative 1.7%.

[0026] The synthesis steps are as follows:

[0027] The first step: add water (mass percentage 16%), pH regulator, caprolactam and fresh milk grade casein into the mixing vessel in turn and stir, the stirring speed is 300rpm, and the stirring time is 20min to obtain a homogeneous mixture of the components I;

[0028] Step 2: Heat the above-mentioned stirring container so that the temperature inside the container rises to 60°C, and keep it within this temperature range for 60 minutes. During this process, continue stirring according to the above-mentioned stirring speed;

[0029] Step 3: Add water (60% by mass) into the stirring container, and start to cool down to 30°C at the same time, and con...

Embodiment 2

[0032] A water-based pearlescent medium used for water-based decorative paper printing ink. The raw material components are: 4.3% of casein, 80% of water, 1.0% of caprolactam, 1.0% of pH regulator, 12% of water-based polyurethane resin, disinfectant Foaming agent 0.5% and water-based preservative 1.2%.

[0033] The synthesis steps are as follows:

[0034] Step 1: Add water (20% by mass), pH adjuster, caprolactam and fresh milk grade casein into the mixing container in sequence and stir at a stirring speed of 400 rpm for 20 minutes to obtain a homogeneous mixture of the components I;

[0035] Step 2: Heat the above-mentioned stirring container so that the temperature in the container rises to 62°C, and keep it within this temperature range for 60 minutes. During this process, continue stirring according to the above-mentioned stirring speed;

[0036] Step 3: Add water (60% by mass) into the stirring container, and start to cool down to 28°C at the same time, and continue stir...

Embodiment 3

[0039] A water-based pearlescent medium used for water-based decorative paper printing ink, the raw material components are: 5.0% of casein, 73% of water, 2.0% of caprolactam, 1.0% of pH regulator, 15% of water-based polyurethane resin, disinfectant Foam agent 2% and water-based preservative 2%.

[0040] The synthesis steps are as follows:

[0041] Step 1: Add water (15% by mass), pH adjuster, caprolactam and fresh milk grade casein into the stirring vessel in sequence and stir at a stirring speed of 200 rpm for 20 minutes to obtain a homogeneous mixture of the components I;

[0042] Step 2: Heat the above-mentioned stirring container so that the temperature inside the container rises to 64°C, and keep it within this temperature range for 60 minutes. During this process, continue stirring according to the above-mentioned stirring speed;

[0043] Step 3: Add water (58% by mass) into the stirring container, and start to cool down to 25°C at the same time, and continue stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com