A method for producing an electroplated lamp holder

A production method and technology of lamp holders, which are applied in the direction of electrolytic components and electrolysis processes, etc., can solve problems such as the top of the lamp holder being stuck into the bottom of other lamp holders, uneven plating, and many defective products, so as to improve market competitiveness, lower production costs, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

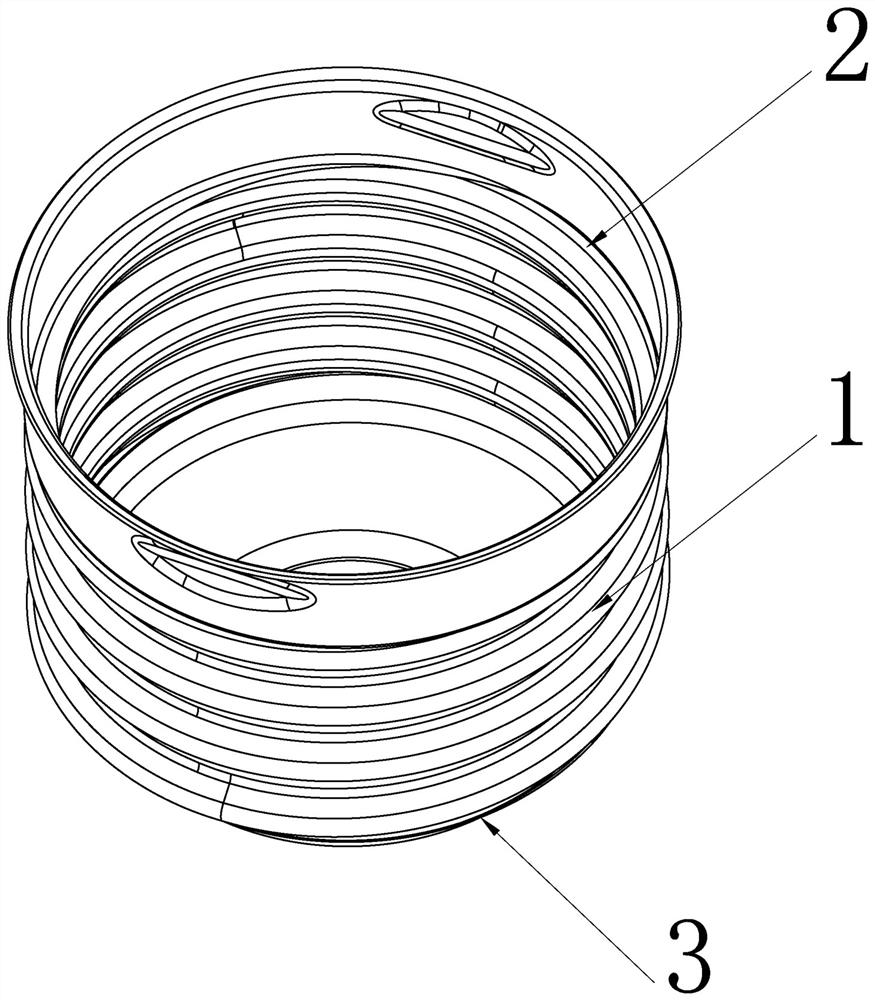

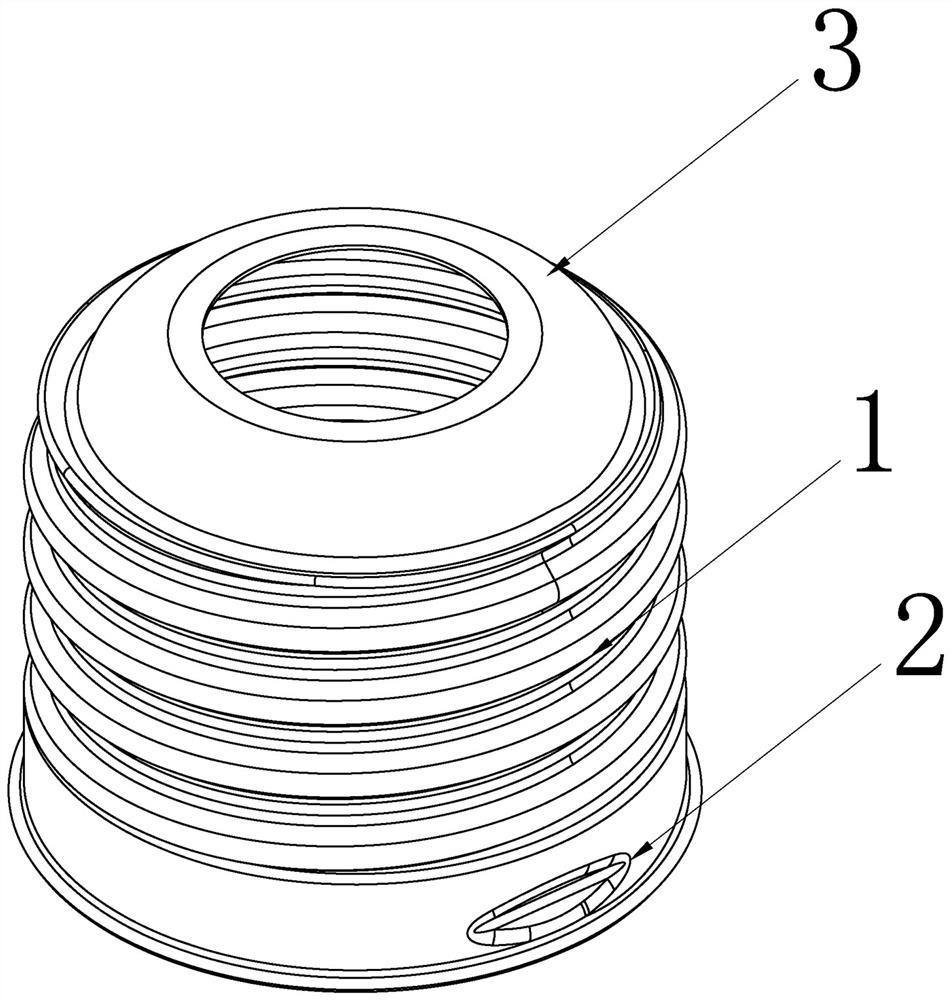

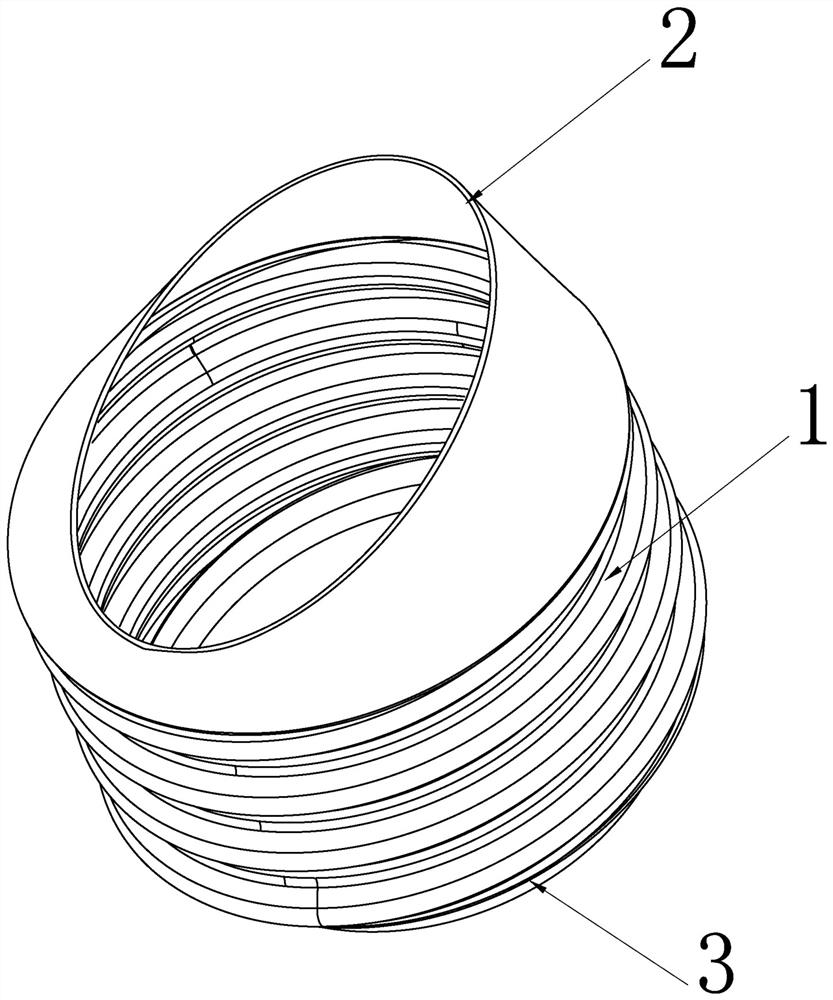

[0021] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A method for producing an electroplated lamp cap, characterized in that it comprises the following steps:

[0022] A: Put the molded lamp holder 1 into the flattening mold;

[0023] B: The flattening mold crushes the top 2 of the lamp cap 1. After the top 2 of the lamp cap 1 is flattened, the minimum width of the opening is smaller than the diameter of the bottom 3 below the lamp cap 1; after the top 2 of the lamp cap 1 is flattened , with an oval opening.

[0024] C: Place the flattened lamp cap 1 randomly into the drum;

[0025] D: put the roller with the lamp cap into the electroplating tank for barrel plating;

[0026] E: Clean the lamp holder after electroplating;

[0027] F: Place the electroplated lamp cap 1 into a rounding mold for rounding, so that the top 2 of the lamp cap 1 returns to a round finished product.

[0028] Described steps C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com